Discover a professional 3D printing powder supplier

Okay, below is the blog post concentrating on steel 3D printing, written in a natural, streaming style with basic language, following your details demands.

(how does the metal 3d printing process work)

How Does the Metal 3D Printing Refine Job?

Think of building facility metal parts layer by tiny layer, straight from a digital design. That’s the magic of metal 3D printing. Forget traditional methods like reducing or casting huge blocks of metal. This innovation constructs shapes directly. It opens up doors to unbelievable styles and strong components. Let’s explore just how it works.

1 What is Metal 3D Printing? .

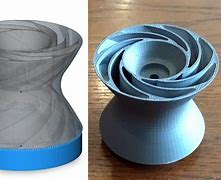

Steel 3D printing is a manufacturing method. It develops solid metal objects straight from computer data. Think about it like a very precise, powerful printer. Rather than ink, it makes use of steel. The maker builds the object slice by piece. These pieces are exceptionally thin. This layer-by-layer method is called additive production. It varies from subtractive methods like milling. Milling cuts away material from a block. Metal 3D printing includes material only where required. This lowers waste considerably. Usual names include Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). These names describe the specific ways lasers fuse steel powder. The core concept stays building layer upon layer.

2 Why Pick Metal 3D Printing? .

Why choose steel 3D printing over older strategies? It uses one-of-a-kind benefits. Style liberty is a huge advantage. You can produce forms impossible with machining or spreading. Believe elaborate lattices inside a part. Assume hollow structures or internal networks. These attributes enhance performance or reduce weight. The procedure excels at making complicated geometries. It’s ideal for prototypes. You obtain useful metal components quickly for screening. Need a personalized part? Metal 3D printing is perfect for low-volume production. It avoids expensive tooling required for spreading. Product efficiency is another plus factor. It makes use of just the steel required for the part itself. Little obtains thrown away. This conserves money on costly alloys. It enables part combination as well. You can integrate multiple components right into one published item. This streamlines setting up and enhances reliability.

3 Exactly How Does Metal 3D Printing Job? .

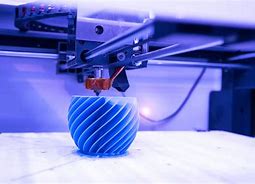

Just how does the machine actually build a steel part? The most usual approach utilizes a laser and metal powder. First, a computer system design gets sliced right into hundreds of thin layers. The equipment prepares a construct system inside a chamber. A slim layer of great steel powder spreads over this system. An effective laser checks across the powder bed. The laser light beam follows the form of the very first layer piece. The laser’s warmth melts the steel bits together. It produces a solid cross-section of the part. The construct platform after that reduces slightly. A new layer of powder spreads over the previous one. The laser thaws the brand-new powder. It additionally bonds it to the layer listed below. This cycle repeats over and over. Layer builds on layer. Gradually, the whole component forms inside the powder bed. Surrounding powder supports the structure throughout printing. After printing finishes, the chamber cools. Service technicians get rid of the block of powder consisting of the published component. They remove the component from this block. Excess powder gets reused for future use. The printed part typically requires additional steps. These steps include eliminating assistance structures. Heat therapy is common as well. It eases interior tensions. Finally, surface ending up may be applied. This achieves the desired look.

4 Where is Steel 3D Printing Used? .

Steel 3D printing finds usages throughout several demanding fields. Aerospace firms like it. They publish light-weight, strong elements for jets and rockets. Believe turbine blades or fuel nozzles. These components typically have complicated inner air conditioning networks. Medical implants profit substantially. Cosmetic surgeons obtain custom-fit hip joints or spine implants. These implants can have porous surfaces. Bone tissue turns into these pores. It produces a stronger bond. The automotive sector uses it as well. High-performance vehicles include published parts. Motorsports groups publish personalized engine elements rapidly. Tooling and manufacturing obtain an increase. Manufacturing facilities print complex injection mold and mildews or jigs. These tools frequently have built-in air conditioning lines. This boosts production rate. Even the power industry utilizes it. Companies print parts for power generation equipment. These parts endure severe temperatures and pressures. Jewelers discover artistic possibilities with precious metals. The applications maintain expanding year by year.

5 Metal 3D Printing FAQs .

(how does the metal 3d printing process work)

People typically have inquiries concerning this modern technology. Allow’s deal with some typical ones. Exactly how solid are metal published parts? They are extremely strong. Correctly printed and treated parts match the strength of commonly made steel. They fulfill sector standards. Is it expensive? The machines and materials cost more than plastic printers. Yet, for facility or custom-made components, it can be affordable general. Think about savings on tooling and product waste. What steels can you publish? Several alloys function. Typical choices consist of titanium, stainless-steel, light weight aluminum, nickel alloys like Inconel, and cobalt-chrome. New materials are continuously being developed. Just how huge can the components be? Develop quantities vary. Industrial equipments deal with parts up to several feet in size. Majorities could need signing up with after printing. How smooth is the surface area? As-printed surface areas have a harsh structure. Post-processing like machining or sprucing up develops smooth surfaces. It depends upon the final application demands.