Discover a professional 3D printing powder supplier

Can You 3D Publish a Piece of Metal?

(can you 3d print a piece of metal)

That concern turns up a great deal. Individuals see plastic trinkets made on desktop computer makers. They wonder if steel works the same way. The brief solution is indeed. Absolutely. You can 3D print metal. It’s not science fiction anymore. It’s genuine production. This technology is altering how we make points. It opens doors to styles as soon as assumed impossible. Let’s dive into the interesting world of metal 3D printing.

1. What is Metal 3D Printing? .

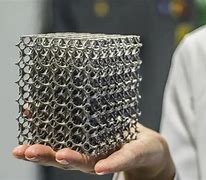

Metal 3D printing isn’t spraying fluid metal from a nozzle. It’s even more complicated. Think of it like welding, yet regulated by a computer. We develop metal items layer by layer. Each layer is extremely thin. It starts with digital design. A 3D design guides the equipment. The machine includes material precisely. It fuses little bits with each other. This blend produces strong metal components. There are different means to do this. Some approaches use lasers. Others make use of electron beams or binders. The objective coincides. Create strong, functional steel parts straight from a computer system file. It’s additive manufacturing for metal. Neglect carving away product. We add it only where required. This process allows incredible flexibility. Picture detailed lattices inside a part. Or complex air conditioning channels winding through a turbine blade. Traditional approaches struggle with these. Metal 3D printing succeeds. It makes the impossible possible.

2. Why Choose to 3D Publish Steel? .

Why trouble? Standard metalworking exists. Casting, machining, building job well. So why include another method? Steel 3D printing provides special advantages. Design liberty covers the checklist. Complex geometries are simple. Think hollow structures. Internal attributes. Organic shapes influenced by nature. These styles are usually stronger and lighter. Weight decrease is important. Aerospace and automobile sectors like this. Lighter parts imply far better fuel efficiency. Next off, it reduces waste drastically. Machining remove up to 90% of the original product. Printing makes use of just the metal needed for the component. This conserves material costs. It’s also more sustainable. Personalization is an additional big win. Required an one-of-a-kind part? Publish one. Required 10 a little different variations? Print them. No costly tooling adjustments called for. This is perfect for models. Also for bespoke medical implants customized to a client’s bone. Rate can be an element as well. For complicated components, printing could be quicker than typical methods. It simplifies assembly. Publish numerous components as one item. This minimizes prospective failure points. It enhances dependability. These benefits drive its fostering throughout industries.

3. Just How Does Metal 3D Printing Work? .

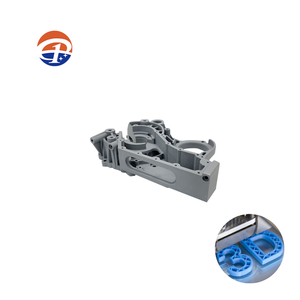

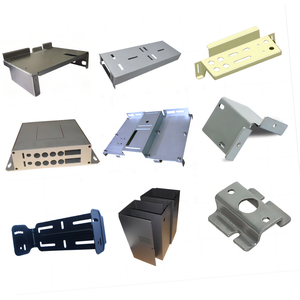

Just how do we transform digital bits right into strong metal? A number of strategies exist. Powder Bed Fusion is really usual. It begins with a bed of fine metal powder. A laser or electron light beam scans the powder bed. It thaws the powder complying with the part’s cross-section. This integrates the fragments right into a solid layer. The build system lowers a little. A new layer of powder spreads over the previous layer. The laser scans once more. This repeats layer by layer. When done, the component sits buried in extra powder. Workers dig it out. This unused powder is frequently reused. Direct Power Deposition works in different ways. Below, a nozzle down payments steel powder or wire. All at once, a laser or electron light beam melts the deposited material. This develops the part. It’s like welding material onto a surface area. This method is great for adding features to existing components. It’s likewise great for large components. Binder Jetting is one more approach. A print head deposits a fluid binder onto a powder bed. The binder glues the powder particles together. This creates a “green” component. Later on, this part goes into a heating system. The binder burns away. The metal particles sinter or melt together. This creates the final metal things. Each approach has its toughness. The selection depends upon the component and its use. Post-processing is usually needed. This includes removing support frameworks. Warmth therapy enhances strength. Surface ending up guarantees smoothness. The journey from data to last component entails several actions. Each step is important.

4. Applications of Metal 3D Printing .

Where is this technology utilized? Everywhere requiring markets press boundaries. Aerospace is a significant player. Gas nozzles with intricate inner channels. Light-weight braces. Generator blades with intricate cooling flows. These components fly in jets and rockets. Weight cost savings here convert directly to sustain cost savings. The medical field embraces it also. Assume personalized hip implants. Patient-specific implants fit flawlessly. Specialists get better end results. Dental crowns and bridges benefit from the precision. Automotive makers use it. Creating lighter elements for electric vehicles extends variety. High-performance auto racing components get printed. Tooling is one more location. Mold and mildews with conformal air conditioning networks cool down quicker. This accelerate production cycles. Energy firms take advantage of it. Printing complicated parts for generators. Parts for oil and gas removal. Even consumer goods see its influence. Premium bicycles make use of printed parts. Custom-made fashion jewelry obtains developed. The applications keep expanding. As costs decrease and materials enhance, a lot more industries will embrace it. It addresses problems typical methods can not.

5. Frequently Asked Questions concerning Steel 3D Printing .

(can you 3d print a piece of metal)

People have concerns. Allow’s deal with some typical ones. Are the parts solid? Yes. Printed steel parts can be very strong. Usually as solid as traditionally made parts. Occasionally more powerful. It relies on the product and process. Post-processing like warmth treatment is crucial. Are they dense? Excellent processes create parts with over 99% density. They execute like functioned metal. Is it pricey? It can be. The makers cost a whole lot. Material prices are more than bulk steel. However, for complex parts, the total price can be reduced. You minimize product waste. You minimize machining time. You save on tooling. The worth remains in the design liberty. What steels can you print? Several. Common ones include stainless-steel, titanium, light weight aluminum, nickel alloys like Inconel. Copper and tool steels are additionally. The list grows continuously. New materials are created. Is it secure? Safety is paramount. Managing fine steel powders calls for care. Operators require training. Appropriate air flow is vital. Equipments run under inert gas for some processes. This avoids oxidation. With correct treatments, it’s secure. How specific is it? Extremely accurate. Resistances are tight. Surface surface may require renovation after printing. Yet the dimensional precision is superb. It measures up to typical machining.