Discover a professional 3D printing powder supplier

What Is Steel 3D Printing? .

(can you print metal on a 3d printer)

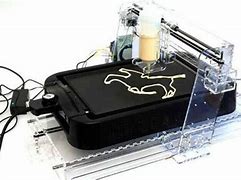

When people ask “can you publish metal on a 3d printer,” they are generally envisioning a regular desktop maker spewing out glossy steel components like magic. The reality is extra nuanced. Yes, you can print steel– but not with the exact same setup you utilize for plastic toys or prototypes. Metal 3D printing makes use of specialized commercial equipments that work extremely in different ways from typical FDM printers. These systems commonly count on lasers or electron beam of lights to melt fine metal powder layer by layer, developing strong metal objects from electronic models. This process passes names like Straight Steel Laser Sintering (DMLS) or Discerning Laser Melting (SLM). While it seems complicated, the core idea is basic: turn electronic designs right into real metal parts without conventional machining. If you’re curious regarding which innovations actually handle steel, have a look at this thorough overview on what sort of 3D printing can publish steel.

Why Publish Steel Instead of Plastic or Machined Components? .

Steel 3D printing fixes issues various other approaches can not. Standard production– like casting or CNC machining– typically wastes product, takes weeks, and battles with complex shapes. Steel printing cuts waste considerably since it only makes use of the product required for the part. It also unlocks geometries impossible with older methods: believe inner air conditioning channels in turbine blades or lightweight latticeworks in aerospace braces. And also, it’s quick for one-off or personalized parts. A cosmetic surgeon requiring a patient-specific dental implant doesn’t need to wait months; a metal printer can generate it in days. Rate, design freedom, and material performance make steel printing important in high-stakes industries. Also enthusiasts occasionally blend metal-like finishes into their projects making use of composite filaments– though these aren’t pure steel. For suggestions on accomplishing that metallic appearance with basic printers, see how to repaint metal filament 3D printing for convincing outcomes.

Exactly How Does Metal 3D Printing Really Function? .

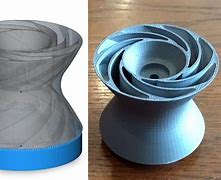

One of the most typical method starts with a slim layer of metal powder spread throughout a build plate. A high-powered laser after that traces the cross-section of the component, thawing the powder into a solid layer. The platform goes down somewhat, one more layer of powder is added, and the process repeats until the item is complete. After printing, the component sits inside a powder bed and must be carefully gotten rid of, cleansed, and frequently heat-treated to ease inner stress and anxieties. Some systems even print in vacuum cleaner chambers using electron light beams instead of lasers– suitable for responsive metals like titanium. These machines cost hundreds of hundreds of bucks and require trained drivers, so they’re mainly found in manufacturing facilities or service bureaus. That stated, newer “bound metal” systems let smaller sized shops shape metal-infused filament or poles, then sinter them in a furnace to burn binders and fuse the steel. It’s a two-step dancing, yet much more accessible. If you’re checking out crossbreed methods, you may also take into consideration adding real metal parts like springs post-print– discover exactly how at how to include steel springtimes to 3D published models.

Where Is Steel 3D Printing Utilized Today? .

Aerospace leads the charge. Jet engines currently include gas nozzles printed as single pieces instead of loads of welded components– lighter, stronger, and much more trustworthy. In medicine, custom titanium hip implants match individuals’ composition flawlessly, boosting healing times. Automotive business utilize steel printing for quick prototyping of engine parts and even limited-run efficiency parts. Tooling is one more big area: injection molds with conformal cooling channels improve production rate and component high quality. Even jewelry manufacturers adopt it for complex, unique styles that would certainly be also costly or breakable to cast. While consumer access remains restricted as a result of cost and intricacy, the ripple effects touch day-to-day life– from much safer airplanes to much better medical care. As devices obtain less costly and easier to run, anticipate to see more little suppliers taking on metal printing for specific niche yet crucial applications.

FAQs About Printing Metal on a 3D Printer .

Can my home 3D printer print real metal?

No. Requirement FDM printers thaw plastic, not metal. Some filaments include steel powder mixed with plastic, however after printing, they still need unique processing (like sintering) to become solid steel– and most home customers do not have heaters efficient in getting to the needed temperature levels.

Is metal 3D printing expensive?

Yes, especially ahead of time. Industrial equipments set you back $200,000 to over $1 million. However, for facility or low-volume parts, it can be less costly than standard techniques when you factor in decreased labor, tooling, and material waste.

What metals can be printed?

Usual alternatives consist of stainless-steel, titanium, aluminum, cobalt-chrome, and nickel alloys like Inconel. Each has details properties fit to different atmospheres– deterioration resistance, high-temperature stamina, biocompatibility, and more.

Exactly how solid are 3D-printed metal components?

Typically as solid as– or stronger than– built or cast matchings, given they’re printed and post-processed appropriately. Thickness usually exceeds 99.5%, making them appropriate for structural and safety-critical roles.

Do I require special software program?

Yes. You’ll require slicing software program suitable with metal systems, plus devices for support generation, thermal simulation, and distortion forecast. Several commercial systems come with proprietary suites developed for their certain hardware.

Can I incorporate steel and plastic in one print?

(can you print metal on a 3d printer)

Not in a single process. But you can design settings up that join published steel and plastic parts later. Some progressed study checks out multi-material printing, but it’s not yet traditional or inexpensive for a lot of users.