Discover a professional 3D printing powder supplier

just how to divide 3d metal print from print bed

(how to separate 3d metal print from print bed)

What is a 3D steel print and why does it stick so strongly to the print bed .

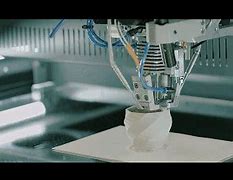

A 3D steel print is a strong object built layer by layer utilizing powdered steel and a high-energy laser or electron beam of light. This procedure happens inside a controlled chamber, usually under inert gas or vacuum cleaner. The print begins on a level surface called the print bed. During printing, the initial layer of metal powder melts and merges straight onto this bed. Since steel expands when hot and contracts as it cools down, the component bonds snugly to the bed through thermal stress and anxiety and metallurgical attachment. That solid bond guarantees the part stays put during printing however makes removal difficult later. If you are new to this area, you can learn more regarding what 3D metal printing actually goes to this overview.

Why separating the print from the bed matters .

Leaving a metal print adhered to the bed isn’t simply inconvenient– it can harm both the component and the maker. If you require it off without care, you might crack delicate attributes or warp thin wall surfaces. Worse, you might damage or damage the print bed itself, which influences future builds. A tidy splitting up protects dimensional accuracy and surface coating. It additionally conserves money and time. Reusing the construct plate without damage ways fewer replacements and regular outcomes. And also, if support structures were made use of– and they generally remain in steel printing– those require to find off easily also. Comprehending the materials made use of for those supports helps plan your elimination technique, as discussed in this source.

How to securely eliminate a 3D steel print from the print bed .

Beginning by allowing the whole develop cool off completely. Hurrying this step risks thermal shock or warping. Once cool, place the develop plate on a stable work surface. The majority of professionals make use of a band saw or cable EDM (electric discharge machining) to cut the part off close to the base. If you don’t have access to those devices, a sturdy carve and mallet can work– yet just if the part is thick enough to take care of influence. Faucet gently along the interface between the component and the bed. Never pry from the leading or sides; that invites bending or breaking. For smaller sized prints, some stores use pliers with soft jaws, however again, go sluggish. After the main part is cost-free, you’ll still have remaining stubs or support residues. These obtain cleaned up with grinding, sanding, or milling. Constantly put on security gear: handwear covers, eye security, and a respirator for metal dirt. If you’re curious about just how hot points really obtain during printing– which influences how stubborn that bond ends up being– take a look at this short article.

Applications where clean separation makes a real difference .

In aerospace, also a tiny distortion from harsh elimination can mess up a turbine blade or fuel nozzle. Medical implants like hip stems should satisfy rigorous surface area smoothness standards– any gouge from careless detachment might cause denial inside the body. Automotive firms utilize steel 3D printing for lightweight brackets and custom fittings; these usually go straight right into performance testing, so geometry has to remain true. Even in tooling and mold-making, where interior cooling networks are common, a clean break makes sure those great passages aren’t squashed or obstructed. In all these instances, the method you pick to separate the print straight impacts function, security, and expense. That’s why skilled teams treat removal as a vital action– not an afterthought.

Frequently asked questions concerning dividing 3D metal prints from the print bed .

1. Can I simply draw the component off by hand.

No. Steel prints are merged at a tiny level. Trying to tug them off will likely break thin sections or leave portions behind.

2. Do all metal 3D printers use the exact same kind of bed.

The majority of use flat steel or light weight aluminum plates, but some systems use recyclable substratums or customized components. Always check your device’s guidebook.

3. Is heat ever utilized to help removal.

Some stores warm up the develop plate somewhat to ease stress, but this is unusual and risky. Overheating can harden the component or deteriorate it.

4. Suppose the part won’t move also after cutting.

That normally implies the preliminary cut wasn’t deep enough. Return with your saw or EDM and cut closer to the bed surface area. Perseverance repays.

5. Can I reuse the print bed as soon as possible after elimination.

Just if it’s completely level and clean. Examine for damages, scrapes, or leftover material. Light machining or polishing may be needed prior to the following work.

6. Exist unique devices simply for this job.

Yes. Devoted component elimination stations exist, typically with clamps and directed cutters. Yet numerous tiny stores take care of well with typical workshop devices and careful method.

7. Does the type of metal affect just how tough it is to get rid of.

(how to separate 3d metal print from print bed)

Absolutely. Stainless-steel sticks differently than titanium or aluminum. Each alloy has its own thermal habits and bonding strength. Recognizing your material assists you pick the ideal elimination approach. You can discover common printing products in even more information at this page.