3D баҫма порошок менән тәьмин итеүсе профессиональ асыу

PRODUCT PARAMETERS

Description

Overview of ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line

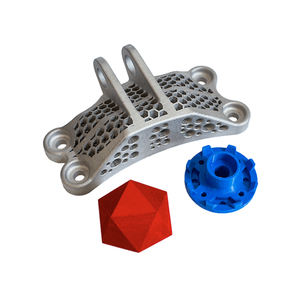

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects by depositing materials layer by layer based on digital designs. This process opens up a new world of possibilities in product design, customization, and production, revolutionizing various industries including healthcare, аэрокосмос, automotive, consumer goods, һәм башҡалар.

Customization & Personalization: One of the key advantages of 3D printing is its ability to create highly customized products tailored to individual needs or preferences, from prosthetics to fashion accessories.

Complex Geometry: 3D printing excels at producing intricate shapes and geometries that would be extremely challenging or impossible to manufacture using conventional methods, such as internal lattice structures or organic forms.

Rapid Prototyping: It significantly speeds up the product development cycle by enabling designers and engineers to quickly produce physical prototypes for testing and refinement.

On-Demand Manufacturing: The technology supports small-batch or even one-off production runs economically, reducing the need for large inventories and allowing for just-in-time manufacturing.

Material Diversity: A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, composites, and even biomaterials, each offering unique properties for specific applications.

Reduced Waste: As compared to subtractive manufacturing techniques, 3D printing only adds material where needed, leading to less waste and a more sustainable manufacturing process.

Features of ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line

Design Flexibility: The technology enables the realization of complex designs without the constraints of traditional manufacturing tools and molds.

Functional Integration: Parts can be designed with integrated features such as channels, cavities, or interlocking components, which can enhance functionality or simplify assembly.

Lightweight Structures: Advanced 3D printing techniques allow for the creation of lightweight yet strong structures through optimized designs and the use of lattice structures or composite materials.

Improved Performance: By precisely controlling material composition and structure, 3D printed parts can exhibit enhanced mechanical, thermal, or electrical properties.

Cost-Efficiency for Complexity: While 3D printing may not always compete with mass-production methods for simple parts, it becomes increasingly cost-effective as the complexity of the part increases.

Innovative Applications: From medical implants that match a patient’s anatomy perfectly to aerospace components that reduce weight and increase efficiency, 3D printing pushes the boundaries of what’s possible in product design and engineering.

(ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line)

Specification of ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line

This device makes 3D printer filament. It utilizes abdominal or PLA plastic. You feed plastic pellets right into the receptacle. The machine thaws the plastic inside the barrel. A solitary screw pushes the melted plastic forward. Heating units regulate the melting temperature level specifically. The melted plastic is compelled with a shaping die. This die forms the plastic right into a thin strand. The strand comes out hot and soft. It requires to cool quickly. Cooling containers with water draw warm away quick. This quits the filament from flawing. Specific pullers get hold of the cooled down filament. They extend it somewhat. This ensures the filament diameter stays consistent. Size control sensing units check the filament size non-stop. The equipment readjusts automatically if needed. Regular diameter is important for good 3D printing. After sizing, the filament goes onto a spool. A winding system rolls it up nicely. The spool holds the filament on-line. This arrangement is a full production line. It transforms plastic pellets into finished filament spindles. The machine is built for integrity. It competes extended periods without stopping. You obtain premium filament every time. Operators discover it very easy to utilize. Controls are uncomplicated. Changing between ABS and PLA is straightforward. Upkeep demands are reduced. This system assists you produce your own filament successfully.

(ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line)

Applications of ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line

This machine makes ABS and PLA filament for 3D printers. It takes raw plastic pellets and transforms them right into usable spindles. You need this if you make or utilize 3D printing filament. ABS and PLA prevail plastics. They are popular for lots of projects. The device heats up the plastic pellets. The pellets melt inside the extruder barrel. A solitary screw presses the thawed plastic ahead. The plastic is required via a tiny opening. This opening shapes it right into a slim hair. The strand obtains cooled off right after. Air conditioning makes it strong once more. You can manage just how thick the filament is. This control is really crucial. Consistent density makes sure great printing outcomes. The completed filament gets wound onto a spool. The spindle awaits your 3D printer. Utilizing this equipment allows you produce your own customized filament. You can select shades. You can mix materials. You can make special blends. Companies utilize these machines for production. They make large amounts of filament to sell. Makerspaces sometimes have them also. Hobbyists can produce their own plastic thread. Abdominal muscle filament is strong and hard. It deals with warm relatively well. Individuals make use of abdominal for vehicle parts, LEGO-like bricks, and functional models. PLA filament is simpler to publish. It comes from plants like corn. PLA is good for models, playthings, and food containers. Schools use PLA filament for tasks. It is safer and smells better when printing. This extrusion line supports both materials. It gives you versatility. You can switch over between abdominal muscle and PLA production. The maker is reputable for constant procedure. It assists fulfill the demand for 3D printing products.

Company Profile

3D Printing Passion is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality 3D printing powder and relative products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality 3D printing materials and relative products, please feel free to contact us or click on the needed products to send an inquiry.

Payment Methods

L/C, T/T, Western Union, Paypal, Credit Card etc.

Shipment

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

5 FAQs of ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line

People often ask about our ABS PLA 3D printer filament machine. Here are five common questions.

What materials can this machine handle? It primarily makes ABS and PLA filament. The machine is built for these popular 3D printing plastics. You can also process similar thermoplastic materials. The design focuses on these specific polymers.

How much filament can it produce? Production speed depends on the filament diameter. For standard 1.75mm filament, expect about 15-25 kilograms per hour. This output suits small to medium businesses well. It provides a good balance of size and productivity.

Is the machine hard to operate? No, the single screw extrusion line is straightforward. Our design emphasizes user-friendliness. Training is provided. Operators learn the controls quickly. It simplifies the filament making process.

How consistent is the filament diameter? Precision control ensures high consistency. The machine maintains tight diameter tolerance. Good diameter control is crucial for reliable 3D printing. You get smooth, even filament output. It minimizes printing problems.

What support comes with the machine? We offer comprehensive technical assistance. Installation guidance is included. Training helps your team operate effectively. Troubleshooting support is available. Maintenance advice keeps the line running smoothly.

(ABS PLA 3D Printer Filament Extrusion Machine/ Filament Production Line for 3D Printing Machine Single Screw Extrusion Line)