Discover a professional 3D printing powder supplier

Steel Magic: Is 3D Printing Really Making Steel Parts?

(3d printed metal?)

People discuss 3D printing plastic toys and models. Now, metal parts are joining the celebration. Fail to remember basic plastic trinkets. Visualize printing facility steel gears, custom medical implants, and even rocket engine components layer by layer. This is metal 3D printing. It sounds like science fiction. It is extremely genuine. It is altering how we make points. Allow’s explore this fascinating globe.

1. Exactly What is 3D Printed Metal? .

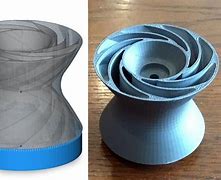

3D published steel is not magic. It is an actual production process. It builds strong metal objects directly from electronic layouts. Think of structure something complicated with microscopic LEGO bricks. Each brick is a small bit of steel. The process adds these bits layer by layer. The layers fuse together. They form a solid, functional metal part. This is various from standard techniques. Conventional methods usually cut away steel (machining). Others compel metal right into molds (spreading). 3D printing adds product just where required. This is called additive production. It allows for forms difficult to make otherwise. Components can have complex internal channels. They can have intricate lattices. They can have organic, running forms. The products used are real steels. Usual ones include stainless steel, titanium, light weight aluminum, and nickel superalloys. Even precious metals like silver and gold can be printed. The outcome is a completely dense steel component. It has the stamina and homes of its typically made counterpart. Often it is even much better.

2. Why Select 3D Printed Steel Over Conventional Approaches? .

Why bother with this new innovation? Conventional metalworking has actually offered us well for centuries. Steel 3D printing supplies unique benefits. The largest is style freedom. Designers are no more limited by the policies of machining or spreading. They can produce forms optimized for efficiency. Think of bone-like frameworks. These structures are strong yet light-weight. Inner cooling networks can comply with the precise heat account of a part. This improves effectiveness. Another vital benefit is personalization. Making a one-off custom-made part using conventional approaches is pricey. It often calls for customized tooling. 3D printing stands out right here. Each part published can be special. No extra tooling is required. This is best for personalized clinical implants. It is perfect for custom aerospace elements. It is fantastic for restricted edition products. Rate is one more variable. Establishing a complicated steel part traditionally takes months. It involves developing, making tooling, and testing models. Metal 3D printing can significantly reduce this. A digital style can end up being a physical model in days. Small manufacturing runs become practical. Complex assemblies can sometimes be printed as a solitary component. This minimizes assembly time and possible failure points. Ultimately, it can lower material waste. Machining frequently begins with a solid block of steel. Much of it gets removed. 3D printing makes use of mostly only the product required for the final part. This conserves expensive steel.

3. Just How Does Metal 3D Printing In Fact Work? .

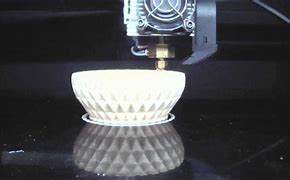

Several modern technologies exist. One of the most common for solid, dense components is Powder Bed Fusion. Visualize a thin layer of great steel powder spread across a build platform. A powerful laser or electron light beam scans the powder surface area. It adheres to the cross-section of the component for that layer. The intense warmth thaws the steel powder particles. They fuse with each other. The construct platform reduces slightly. A new layer of powder is spread. The laser thaws the following cross-section. It also bonds it to the layer below. This repeats layer by layer. The part is built inside a chamber full of inert gas. This prevents the hot metal from oxidizing. After printing, the construct chamber cools. The extra powder is eliminated. It can be recycled. The printed component is typically still attached to the construct plate. Assistance frameworks might be needed. These are eliminated. The component commonly needs warm treatment. This soothes inner anxieties. It enhances the metal’s buildings. Final machining or surface completing may be applied. Various other methods exist. Binder Jetting utilizes a liquid binder to adhesive powder fragments together. The “eco-friendly” part is after that sintered in a furnace to fuse the metal. Directed Power Deposition (DED) feeds steel powder or cable into a thaw pool produced by a laser or electron beam. This is good for repairing components or adding features.

4. Where is 3D Printed Steel Made Use Of Today? (Applications) .

This innovation is moving fast. It is discovering real-world uses. The aerospace market is a significant adopter. Weight is vital for airplane and rockets. 3D printing produces complicated, lightweight components. Gas nozzles, generator blades, and structural brackets are common instances. The clinical area advantages extremely. Surgeons can get patient-specific implants. These implants completely match a client’s composition. Think titanium head plates or hip joints. Oral crowns and bridges are also published. The automobile industry uses it for high-performance parts. Customized competing elements, light-weight prototypes, and intricate air conditioning systems are published. Tooling is another huge location. Shot molds with conformal cooling channels cool down plastic parts much faster. This quicken manufacturing. Power firms use printed components for turbines and exploration devices. Also consumer goods are showing up. High-end bikes include printed titanium lugs. Jewelers develop elaborate layouts impossible to cast. The opportunities keep increasing. It is not simply for prototypes anymore. It is making real, practical end-use parts.

5. Often Asked Questions Concerning 3D Printed Steel .

People have several inquiries regarding this brand-new tech. Let’s deal with some common ones.

Is 3D published metal solid sufficient? Yes. When done correctly, parts satisfy or go beyond the strength of cast or wrought metal. The procedure is securely regulated. Post-processing like warm treatment makes sure great homes.

Just how much does it set you back? Prices are higher than mass production techniques like spreading or marking. It is competitive for complex parts, custom things, or small sets. You stay clear of pricey tooling. Material waste is lower. As machines improve and come to be a lot more usual, costs will certainly go down.

What concerning the surface finish? Printed steel parts usually have a rougher surface area than machined parts. They could show layer lines. Post-processing like machining, polishing, or bead blasting can achieve smooth surfaces. Some applications don’t need a perfect coating.

Can I print any steel? Lots of steels are printable. Common ones are titanium alloys, stainless steels, aluminum alloys, nickel superalloys, and cobalt-chrome. Research study proceeds. More alloys are appearing. Publishing some metals like hard device steels remains challenging.

How huge can components be? Printer develop quantities vary. Desktop machines are little. Industrial printers can build components over a meter long. Larger systems exist. Very large components might be published in sections and joined.

Is it safe? Industrial metal 3D printers run in sealed chambers. Taking care of fine steel powders requires treatment. Correct safety procedures are vital. This consists of air flow and safety tools. The printing process itself is very automated and regulated.

Exactly how precise is it? Accuracy is great. It is commonly within fractions of a millimeter. It relies on the device, product, part style, and post-processing. Tolerances for vital attributes might need machining afterwards.

(3d printed metal?)

Can I print at home? Desktop computer steel 3D printers exist. They are still pricey. They need substantial proficiency. Managing steel powders securely in your home is hard. For now, it is mostly an industrial modern technology.