Discover a professional 3D printing powder supplier

Title: 3D Printed Metal Parts: Are They Driving the Future of Cars?

(are 3d printed metal parts used in cars)

Main Product Keywords: 3D printed metal parts, cars

1. What Are 3D Printed Metal Parts?

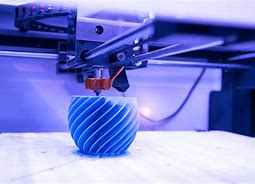

Think about a regular inkjet printer. It builds an image layer by layer using ink. Now, imagine that process, but instead of ink, it uses fine metal powder. Instead of paper, it builds a solid metal object. That’s metal 3D printing, or additive manufacturing. A powerful laser or electron beam melts the powder exactly where needed, following a digital design. Layer by thin layer, a complex metal part takes shape right before your eyes. This isn’t plastic trinkets. We’re talking strong, functional components made from titanium, aluminum, steel, even special alloys. These parts are born from a digital blueprint, not carved from a block of metal. This freedom allows shapes impossible with old methods. Intricate cooling channels inside an engine part? Lightweight lattice structures? No problem. This technology turns digital dreams into tangible, high-performance metal reality.

2. Why Use 3D Printed Metal Parts in Cars?

Car makers face constant pressure: build lighter, stronger, more efficient, and more unique vehicles faster. Traditional manufacturing often struggles here. Metal 3D printing offers solutions. First, weight. Lighter cars use less fuel or battery power. 3D printing lets engineers design parts with internal honeycomb structures or hollow sections, keeping strength but shedding pounds. Second, complexity. Need a part with twisting internal passages for better cooling or fluid flow? 3D printing builds it in one piece. Old methods might need many parts welded or bolted together. Third, customization. High-performance or luxury cars demand unique components. Making custom molds for traditional metal casting is expensive and slow for just a few parts. 3D printing excels at small batches or even one-offs without huge setup costs. Fourth, speed. Prototyping a new part design? 3D printing can turn a digital file into a testable metal prototype much faster than machining or casting. This speeds up innovation. Finally, material efficiency. Traditional machining cuts away most of a metal block. 3D printing uses only the powder needed for the part itself, wasting much less material. It’s a smarter, leaner way to build tough car parts.

3. How Are These Metal Car Parts Actually Made?

Several techniques exist, but two dominate for strong car parts. Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) are very similar. A thin layer of metal powder spreads across a build platform. A high-power laser scans the platform, melting the powder precisely where the part’s cross-section is defined. The platform lowers slightly. Another layer of powder spreads. The laser melts again, fusing to the layer below. This repeats hundreds or thousands of times until the complete part emerges from the powder bed. Electron Beam Melting (EBM) works similarly but uses an electron beam in a vacuum, often for reactive metals like titanium. After printing, the part isn’t ready. It’s still encased in unused powder. Workers carefully remove it. Then, it usually needs heat treatment. This process, called annealing or hot isostatic pressing (HIP), relieves internal stresses and makes the metal denser and stronger. Finally, some machining or surface finishing might be needed. The journey from powder to polished car component is precise, layer-by-layer magic.

4. Where Are 3D Printed Metal Parts Used in Cars Today?

You won’t find them in every family sedan yet, but they’re accelerating into high-performance and specialized areas. Formula 1 and endurance racing teams are big adopters. They use 3D printed titanium hydraulic fittings, intricate turbocharger components, and ultra-lightweight suspension parts. Every gram saved matters on the track. Luxury car makers use them for bespoke elements. Think custom metal dashboard trim, unique gear shift knobs, or lightweight structural brackets for limited editions. Under the hood, complex engine parts are emerging. This includes optimized intake manifolds, lightweight engine brackets, and parts of the cooling system with integrated channels. Exhaust systems benefit too. Lightweight, heat-resistant 3D printed components can handle extreme temperatures. Even brake calipers are being printed. Some high-end cars feature massive, lightweight aluminum calipers made additively, impossible to cast traditionally. Electric vehicles are also exploring this. Lightweight battery enclosures, cooling plates for battery packs, and specialized motor components are potential applications. The technology is moving from prototypes and racing straight into high-value production components.

5. FAQs About 3D Printed Metal Parts in Cars

People have questions about this new tech. Here are common ones:

Are they strong enough? Yes. Properly made 3D printed metal parts can be as strong as, sometimes stronger than, traditionally made parts of the same material. The key is the right process, material, and post-processing. Aerospace already uses these parts for critical systems.

Aren’t they way too expensive? Cost is coming down. For simple, mass-produced parts, traditional methods are often cheaper. But for complex shapes, lightweight designs, or low-volume production, 3D printing can be cost-competitive. It saves money on tooling and reduces material waste. The value is in the design freedom and performance gains.

How long do they last? Just like any car part, it depends. Fatigue life (how long under repeated stress) is a focus. With good design and proper printing/post-processing, these parts meet rigorous automotive durability standards. They are engineered for the job.

Can any metal be printed? Not all, but many common automotive metals can. Aluminum alloys, titanium alloys, various steels (like stainless and tool steel), nickel superalloys, and cobalt-chrome are all printable. New materials are constantly being developed.

(are 3d printed metal parts used in cars)

Will my next car have them? Maybe not your basic model, but increasingly likely in higher-end, performance, or luxury vehicles. As costs decrease and speeds increase, expect to see more 3D printed metal components under the hood and inside the cabin, especially for complex or lightweight applications. The technology is steadily moving towards wider adoption.