Discover a professional 3D printing powder supplier

Can Your 3D Printed Steel Take the Warm? Welding Realities Disclosed! .

(are 3d printed metal parts weldable)

Think of crafting a complicated metal component layer by layer, a task of modern design magic. Currently envision needing to fuse that component to another piece of metal making use of excellent old-fashioned welding. Does this advanced production hold up under the intense embrace of soldering iron? The solution is an unquestionable yes, but it requires cautious factor to consider. Let’s explore the interesting globe of welding 3D printed steel components.

Key Item Keywords: Weldable 3D Printed Metal Parts.

1. What Exactly Are Weldable 3D Printed Metal Components? .

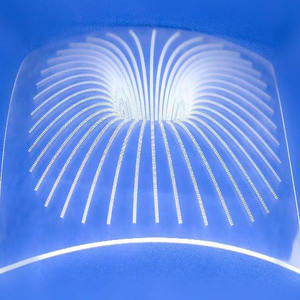

Start with the fundamentals. Weldable 3D published steel parts are elements developed making use of additive manufacturing (AM) methods. These methods fuse metal powder or cable layer by layer based on an electronic layout. Usual approaches consist of Powder Bed Combination (like Careful Laser Melting – SLM or Electron Light Beam Melting – EBM) and Directed Power Deposition (DED). The essential aspect is the product. Not all 3D published metals bonded easily. The most typical weldable products know alloys also utilized in standard welding. Assume stainless steels (like 316L), titanium alloys (like Ti-6Al-4V), nickel-based superalloys (like Inconel 718), and some device steels. These products possess inherent weldability because of their metallurgical residential or commercial properties. The printed part itself must additionally have an ideal microstructure and density. High porosity or internal problems can trigger huge issues during welding. So, weldable 3D printed steel parts are essentially complicated shapes made from tried and tested weldable alloys utilizing AM, possessing the necessary structural honesty to withstand the welding process.

2. Why Would Certainly You Also Intended To Weld 3D Printed Steel? .

This is a fair concern. Why go through the initiative of publishing a component only to weld it later? Numerous strong factors exist. Initially, dimension matters. Industrial metal 3D printers have build quantity limitations. Need a component bigger than the printer? Publish it in sections and weld them with each other. This opens doors for large elements. Second, hybrid production beams here. In some cases, combining AM with typical methods makes ideal sense. Publish a complex feature onto a conventionally made base plate. Bonded a printed cooling channel assembly right into a bigger structure. This leverages the best of both globes. Third, fixings are critical. A high-value published element gets damaged. Repairing it through welding may be far more affordable and faster than printing an entire new one. This is especially real for aerospace or power generation components. Fourth, integrating basic elements is simpler. Weld a threaded insert, a flange, or a sensor place straight onto the printed component. Lastly, style adaptability rises. Designers aren’t restricted entirely by the printer’s dimension. They can develop settings up that are published and then joined. Welding supplies a robust signing up with method for these settings up.

3. Exactly how Do You Efficiently Bonded 3D Printed Metal? .

Welding published metal isn’t exactly like welding wrought steel. You require added treatment. Preparation is king. Cleansing is non-negotiable. Remove all powder deposit, oils, and oxides from the surfaces to be bonded. Any kind of contamination invites flaws. Surface condition matters too. Rough as-printed surfaces may catch contaminants. Machining or grinding the weld joint location smooth is frequently advised. This makes sure good get in touch with and combination. Picking the ideal welding process is important. Some methods work far better than others. Gas Tungsten Arc Welding (GTAW/TIG) is often the leading option. It offers exceptional control over warmth input, which is crucial. Various other alternatives include Gas Steel Arc Welding (GMAW/MIG) and Laser Light Beam Welding (LBW). Electron Beam Welding (EBW) functions well in a vacuum. Friction-based approaches like Rubbing Stir Welding (FSW) also reveal promise. Managing warm input is absolutely crucial. Printed steels can have various thermal properties than their wrought counterparts. Way too much heat can warp the component. It can likewise cause porosity problems or alter the meticulously engineered microstructure near the weld. Pre-heating and post-weld warm treatment (PWHT) might be essential. This depends heavily on the details alloy and the application’s needs. Constantly comply with qualified welding treatments. Checking the procedure on example vouchers printed similarly is highly recommended.

4. Where Are Bonded 3D Printed Steel Parts Made Use Of? (Applications) .

This combination of technologies is finding amazing real-world uses. Aerospace leads the charge. Assume complex fuel nozzles with bonded installations. Think of light-weight structural braces welded into airframe settings up. Fixing pricey turbine blades making use of AM and welding conserves considerable expenses. The power sector benefits as well. Custom components for oil and gas removal manage extreme environments. Power generation wind turbines integrate bonded AM parts. Tooling and molds see benefits. Conformal air conditioning channels published right into mold and mildew cores boost performance. Welding enables connecting standard installing attributes to these custom-made devices. Automotive embraces it, specifically in high-performance locations. Custom consumption manifolds, exhaust parts, and light-weight architectural components make use of bonded published parts. Prototyping gains rate and versatility. Engineers quickly repeat layouts. They weld published prototypes to test assemblies or incorporate with existing systems. Medical gadget production utilizes it for patient-specific implants. Specialists may require one-of-a-kind brackets or supports welded throughout surgery. The opportunities maintain increasing as the technology grows.

5. Frequently Asked Questions: Busting Myths Regarding Welding 3D Printed Metal .

(are 3d printed metal parts weldable)

Numerous concerns swirl around this topic. Allow’s take on some usual ones. Is the weld as solid as the base metal? An appropriately carried out weld on a well-printed component can accomplish stamina really near the base published material. Matching filler metal and proper procedures are essential. Are all published steels weldable? No. Some highly specialized alloys or those prone to splitting are troublesome. Adhere to known weldable alloys like usual stainless-steels, titanium, and nickel alloys. Do I need an unique welder? Not always a “unique” welder. You need a competent welder experienced with the picked process. They need to understand the nuances of welding additively produced product. Most importantly, they have to follow a qualified procedure. Just how do I understand if my published part is weldable? Consult your metal 3D printing company or material distributor. They have information on the weldability of their processes and products. Evaluation the material certificate and printing criteria. Can I bond printed metal to normal steel? Yes, definitely. This is a common application. It’s essential to guarantee the two metals are compatible for welding. Utilize the proper filler metal and treatment made for signing up with those particular products. Does welding mess up the 3D published residential properties? The Warm Affected Zone (HAZ) near the weld experiences high temperatures. This modifies the microstructure. The degree depends upon the product and heat input. Sometimes PWHT is required to recover buildings. Correct procedure lessens unfavorable effects.