Discover a professional 3D printing powder supplier

Can Metal 3D Printing Escape the Support Structure Catch? .

(are support structures required in 3d metal printing?)

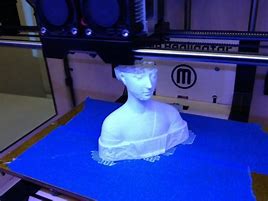

Steel 3D printing, especially laser powder bed fusion, develops complex components layer by marvelous layer. It seems like pure magic. Yet any individual who has seen a construct unravel understands it’s not always smooth sailing. Parts often need extra scaffolding– those assistance frameworks. Are they constantly mandatory? Allow’s explore this necessary element of metal additive production.

1. Just What Are Support Structures in Metal 3D Printing? .

Think about support structures as short-term scaffolding for your steel component. They are printed along with the actual component throughout the build procedure. They aren’t component of the last layout. Their job is simply functional during printing.

These supports literally link to particular locations of the part. They give a solid structure for layers above. Without them, functions hanging over empty space would certainly have nothing to build on. The liquified steel would just drop or droop into the powder bed listed below. The result would certainly be a messy, stopped working print.

Supports appearance various relying on their purpose. Some are thin, lattice-like frameworks touching delicate overhangs. Others are strong blocks anchoring the component strongly to the develop plate. Their shape and thickness are carefully computed by the printing software program. They are made from the very same metal powder as the component itself. This guarantees they bond correctly throughout printing.

2. Why Can Not We Simply Publish Without Assistances? .

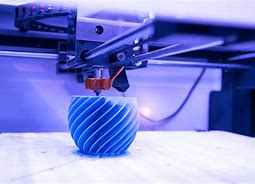

Gravity. That’s the simple, inescapable factor. Metal 3D printing melts little fragments of metal powder making use of an effective laser or electron beam. This liquified metal is unbelievably hot and fluid prior to it strengthens. Visualize trying to build a bridge beginning with the middle span with nothing beneath. It collapses.

In printing, any type of surface area angled too outstanding downwards comes to be a trouble. This is called an “overhang.” If the overhang angle is as well severe (normally past about 45 levels from horizontal), the new layer has insufficient product listed below it to fuse to properly. It requires something solid beneath immediately. Supports give that important structure.

Thermal anxiety is another big element. As layers rapidly thaw and cool, considerable interior stress and anxieties develop within the part. These stress and anxieties can create warping, breaking, or even the part detaching totally from the construct plate. Tactically put supports act like supports. They hold the component strongly in place. They take in some of these tensions. They help keep the part’s specific shape and setting throughout the intense heating and cooling cycles.

3. Just how Do We Layout and Usage Supports Successfully? .

Assistance layout is an essential step in preparing a part for metal 3D printing. It’s not automatic. It calls for skill and experience. Designers use specialized software program to evaluate the 3D version. The software program recognizes locations needing support based upon overhang angles and possible thermal stress and anxiety points.

The objective is constantly “very little but sufficient.” Too many assistances waste product, increase print time, and make post-processing a nightmare. As well few assistances take the chance of print failure or part distortion. Engineers fine-tune several things:.

Kind: Selecting in between fine latticework supports for fragile attributes or strong block supports for high-stress locations.

Placement: Placing supports just where definitely needed, avoiding essential surfaces when possible.

Contact Points: Creating just how the support touches the component. Decreasing call location reduces scarring yet should make sure security.

Density: Readjusting exactly how solid the assistance framework is internally.

Removability: Designing supports that escape easily without damaging the component surface.

Software application helps create assistances, yet experienced judgment is important. The developer needs to understand the product behavior, the printing process specifics, and the component’s last application. Occasionally, a little style adjustment to the component itself can significantly reduce the requirement for complex supports.

4. Where Are Support Frameworks The Majority Of Important? (Applications) .

Support needs differ wildly relying on what you’re publishing and its geometry. Some applications heavily rely upon them, others much less.

Facility Internal Networks & Cavities: Parts like intricate warmth exchangers or gas injectors typically have deep, encased flows. Supports are vital inside these voids to stop collapse during printing. Removing them after that is tough however required.

Large Overhangs & Cantilevers: Features like vast braces, wing-like structures, or any considerable forecast extending flat call for durable assistance underneath. Think of the wings on a steel dragon sculpture– they need strong scaffolding.

Great Features & Thin Walls: Delicate frameworks, like slim fins or latticework networks, are susceptible to warm distortion. Light-weight, accurate assistances help maintain them during the build.

Construct Plate Anchoring: Virtually every component needs some kind of support structure connecting it straight to the build plate. This prevents bending and detachment caused by thermal anxieties. This base assistance is normally the thickest and strongest.

Minimizing Distortion in Essential Areas: Also get rid of relatively great angles might require assistances in details zones prone to bending. This is common near sharp edges or abrupt changes in cross-section.

On the other hand, get rid of mainly gentle inclines upwards (like a pyramid) or straightforward vertical walls typically require marginal support, mostly just at the base.

5. FAQs: Burning Concerns Concerning Steel Printing Supports .

Can we ever before publish metal get rid of ZERO supports? It’s exceptionally unusual for complicated components. Also basic geometries generally need some base anchoring to the construct plate to take care of stress and anxiety. Really support-free metal printing is a major research study goal but not yet a prevalent truth for most applications.

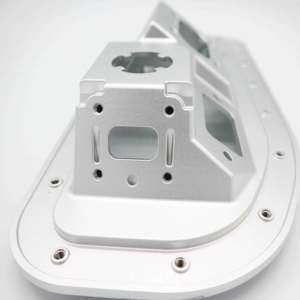

Do supports damage the part surface area? Commonly, yes. Removing supports can leave small marks, scars, or roughness where they were connected. This is a key difficulty. Mindful style lessens call location. Post-processing like machining or sprucing up is normally required on those surface areas to fulfill final high quality standards.

Is getting rid of assistances challenging? It can be! Eliminating them is a considerable component of post-processing. Approaches include cord EDM (cutting), hands-on splitting, machining, grinding, or chemical etching. It requires time, effort, and ability. Support design straight impacts exactly how tough elimination is. Supports deep inside networks are the most difficult.

Do supports waste a great deal of product? They definitely consume product. This unused metal powder in the supports is commonly recycled. But it still includes expense due to added printing time, powder handling, and post-processing energy. Reducing assistance volume is a significant emphasis for expense decrease.

Are there choices to standard assistances? Research is recurring! Concepts like utilizing various laser specifications for overhangs, specialized powder recoating, or dissolvable assistance products (typical in plastics, extremely hard in metals) are being explored. Some advanced software program can create highly maximized, marginal assistances that escape extra conveniently. But for now, traditional assistances are the conventional workhorse.

(are support structures required in 3d metal printing?)

Can split style eliminate the demand for assistances? Smart style assists a lot! Techniques consist of adding short-lived sacrificial features, developing independent angles (higher than 45 degrees), staying clear of huge level overhangs, and rounding sharp corners. Layout for Additive Production (DfAM) is vital for decreasing assistance dependence.