Discover a professional 3D printing powder supplier

Can Your 3D Printed Metal Take the Heat? Opening Hardness Potential

(can 3d printed metal be hardened)

People see 3D printed metal parts. They look amazing. They have intricate forms. People question their stamina. Can these components be made harder? Can they hold up against tough jobs? The answer is indeed. 3D published metal can be set. This opens up numerous doors. It makes printed components far more useful. We will discover this procedure.

1. What is 3D Printed Steel Hardening?

3D published metal solidifying is a therapy. It makes the metal more powerful. It makes the metal harder. It makes the steel last much longer. Consider a knife blade. A soft blade dulls fast. A hardened blade maintains its edge. The same concept relates to printed parts. Setting adjustments the metal’s interior framework. The small grains inside obtain repositioned. This makes the material withstand wear better. It aids the part take care of pressure without flexing. Setting is not magic. It uses scientific research. It uses regulated procedures. These processes enhance the steel’s residential or commercial properties. Hardening prevails for conventional steel parts. Currently it helps 3D published ones too. It’s an important step for serious applications.

2. Why Harden 3D Printed Steel?

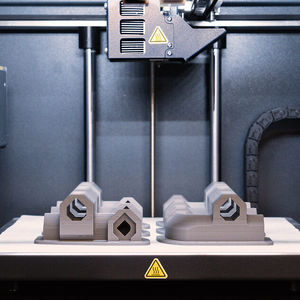

Printing metal is facility. The process entails melting steel powder. It develops layers. This develops components. These parts might not be solid enough right away. They may have small openings inside. They could have stress and anxieties. Hardening solutions these concerns. It makes the component denser. It gets rid of interior weaknesses. It increases the solidity substantially. A hardened component puts on down slower. It lasts much longer. It can handle heavy loads. It survives in harsh settings. Consider gears. They require solidity. Think of reducing tools. They require firmness. Think about parts inside engines. They need solidity. Without hardening, published components might fall short. Setting makes them reliable. It makes them all set genuine work. It changes them from prototypes right into practical parts. It adds worth. It validates the cost of printing.

3. Just How is 3D Printed Metal Hardened?

A number of approaches harden 3D published metal. Warm therapy is very common. The part enters into an unique stove. It gets warmed to high temperatures. The temperature level is specific. The time is managed. After that it cools. This air conditioning can be fast. It can be slow-moving. The technique depends on the metal. Stainless steel typically requires quenching. That means rapid air conditioning. Titanium might need slow-moving air conditioning in air. Heat therapy changes the microstructure. It makes the steel harder. One more technique is Hot Isostatic Pushing (HIP). HIP is powerful. It subjects the part to high warm. It also applies really high pressure. This stress comes from all sides. It squashes tiny internal pores. It makes the part almost strong. It gets rid of problems. HIP substantially boosts toughness. It improves exhaustion life. Sometimes both approaches are utilized. The choice depends upon the steel. It depends on the part’s objective. It relies on the required homes. Experts select the most effective procedure.

4. Applications of Hardened 3D Printed Metal

Hard 3D published steel is utilized everywhere. Aerospace is a huge customer. Plane components encounter extreme anxiety. They need to be solid. They require to be light-weight. Solidified published parts fit perfectly. Generator blades benefit substantially. Automotive uses hard parts too. High-performance automobiles need strong parts. Custom tools are printed and set. Clinical implants are printed. They are hardened for longevity. They go inside the human body. They should not stop working. Industrial devices are published. Pierce bits, reducing jigs, molds. They are solidified to stand up to wear. They last much longer. They do better. Customer items use solidified parts. Resilient sporting goods. Reliable electronics enclosures. The opportunities are large. Hardening makes published steel competitive. It replaces generally made components. It supplies layout freedom plus stamina.

5. FAQs Concerning 3D Printed Steel Hardening

(can 3d printed metal be hardened)

Many individuals have concerns. We address some common ones. Does solidifying alter the component’s shape? Normally, no. Modern procedures are accurate. Components keep their dimensions well. Small adjustments may happen. Good planning reduces this. Can all 3D published steels be hardened? Most common ones can. Stainless-steels like 17-4 PH harden well. Device steels solidify well. Titanium alloys set well. Some light weight aluminum alloys can be solidified. Examine the certain material. Not every steel reacts the very same. Is hardening costly? It includes cost. Warmth therapy costs much less. HIP costs a lot more. The cost depends on the part dimension. It relies on the process. Take into consideration the value. A solidified part lasts much longer. It executes far better. Typically the expense deserves it. Just how strong can hardened printed metal obtain? Very strong. Correctly hardened components match created steel stamina. Occasionally they surpass it. It depends upon the steel. It depends on the process. It depends on the original print quality. Do I constantly need solidifying? No. Not every component needs it. Prototypes might be fine soft. Non-critical components could be fine. Parts under heavy tons demand hardening. Parts encountering wear requirement solidifying. Parts in important applications require solidifying. Evaluate the part’s work. Choose intelligently.