Discover a professional 3D printing powder supplier

The All-Plastic Firearm Fantasy: Can You Really Print a 3D Gun Without Metal?

(can a 3d gun be printed without metal plate)

The idea sounds ripped from a sci-fi thriller: download a blueprint, press print, and out pops a functional firearm made entirely of plastic. No metal plates, no serial numbers, just polymer and potential. But is this “ghost gun” dream achievable? Let’s dive deep into the reality of printing a gun without metal.

1. What is a “3D Printed Gun” and the “Metal Plate”?

A 3D printed gun is exactly what it sounds like. It’s a firearm where key components are created using a 3D printer. This machine builds objects layer by layer from materials like plastic filament (often PLA or ABS). The “metal plate” refers to a crucial part required by many designs. This isn’t just any piece of metal. It acts as the firearm’s lower receiver – the core component legally defined as the gun itself in many places. This metal plate houses critical parts like the trigger assembly and withstands immense forces when the gun fires. Think of it as the skeleton holding everything together. Without it, most common 3D printed gun designs simply cannot function. The plastic parts alone lack the necessary strength and durability.

2. Why Do People Want to Avoid the Metal Plate?

The desire to skip the metal plate stems from a few key motivations. First is the idea of a truly “untraceable” weapon. Metal components can potentially be detected by security scanners or carry serial numbers. A purely plastic gun could theoretically bypass these measures. Second is ease of access. Getting a metal plate often requires machining tools or purchasing a regulated part. Printing everything in plastic seems simpler, faster, and cheaper. Third is the allure of complete anonymity. Download a file, print it at home, and possess a firearm with no background check or record. This appeals to those seeking to circumvent laws or avoid detection. It represents the ultimate “ghost gun” ideal for some. The technical challenge itself is also a motivator for tinkerers and experimenters.

3. How Do Current Designs Handle the Metal Requirement?

Right now, achieving a functional firearm entirely from plastic is incredibly difficult and unreliable. Most viable designs absolutely require metal. The metal plate acts as the lower receiver. It holds the fire control group (trigger, hammer, disconnector). This part experiences massive stress during firing. Plastic alone usually cracks or deforms under this pressure. Designs like the popular “Liberator” pistol famously needed a simple metal nail as a firing pin. Even more robust designs, like those based on the AR-15 platform (e.g., the “FGC-9”), rely heavily on metal parts. These include the barrel liner (a metal tube inserted into the printed barrel), the bolt assembly, springs, and fasteners. The bolt slams back and forth with huge force. Plastic bolts shatter quickly. The barrel must contain the explosive pressure of the round and provide rifling to spin the bullet. Plastic barrels bulge, melt, or fail catastrophically. Attempts to make these parts from plastic alone result in guns that are dangerous to the user, prone to rapid failure, or wildly inaccurate after just a few shots. Some experiment with exotic, ultra-strong plastics or carbon fiber reinforcement, but these are expensive, hard to print, and still fall short of metal’s performance and longevity.

4. Applications: Where Does the All-Plastic Idea Stand Now?

The dream of a reliable, entirely plastic 3D printed gun remains largely science fiction. Its practical applications are severely limited. It’s a subject of intense online discussion, experimentation in hobbyist and anarchist circles, and significant concern for law enforcement and regulators. However, successful, repeatable demonstrations of durable, safe, and accurate all-plastic firearms are virtually non-existent. The technology simply isn’t there yet. Plastic polymers commonly used in affordable desktop 3D printers lack the necessary tensile strength, heat resistance, and impact toughness. The forces involved in firing a bullet are extreme. Think thousands of pounds per square inch of pressure in the chamber, intense friction in the barrel, and violent recoil forces. Common printing plastics soften well below these temperatures. Attempts often result in single-shot devices that might fire once, but risk exploding in the user’s hand or becoming unusable immediately after. The real-world application is currently confined to dangerous proof-of-concept experiments, not practical weapons. Law enforcement worries more about hybrid guns – those combining printed parts with readily available metal components like barrels or bolts kits.

5. FAQs: Burning Questions About Plastic Pistols

Can you 100% print a working gun with no metal at all? Realistically, no. Not a reliable, safe, or durable firearm using current common 3D printing tech and materials. Something critical will likely be metal, or the gun will fail quickly.

What parts absolutely need to be metal? The barrel (or at least a metal liner), the bolt or breech face, the firing pin, and springs are almost always metal in functional designs. The chamber containing the explosion must be incredibly strong.

Isn’t the plastic strong enough? Not for critical pressure-bearing parts. Standard 3D printing plastics are brittle under impact or soften with heat. The forces inside a firing gun are far beyond what these plastics can reliably handle multiple times.

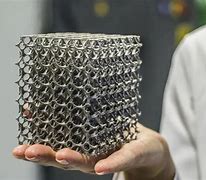

What about exotic plastics? Materials like PEEK or PEKK are much stronger and more heat-resistant. They are extremely expensive, require specialized high-temperature printers, and are difficult to work with. Even then, they often still fall short of steel’s performance and are not accessible for typical “ghost gun” printing.

Could future technology make it possible? Maybe. Advancements in materials science (stronger, heat-resistant polymers) and printing methods (like metal 3D printing becoming cheaper) could change things. But metal remains the superior material for handling the extreme conditions inside a firearm. Regulations will also likely evolve to counter new threats. The all-plastic gun remains a significant technical and regulatory hurdle.

(can a 3d gun be printed without metal plate)

Is it legal? Laws vary wildly by country and even within countries (like state laws in the US). Manufacturing any firearm for personal use may be legal in some places but often requires serialization and background checks for certain components. Possessing or manufacturing unserialized “ghost guns,” regardless of material, is illegal in many jurisdictions. Laws are changing rapidly in response to this technology. Never assume it’s legal.