Discover a professional 3D printing powder supplier

Steel Magic: Can Your 3D Printer Actually Print Steel? .

(can a 3d printer print metal?)

The globe of 3D printing continuously impresses. We see plastic toys, intricate designs, also food arise layer by layer. But what about metal? Can a 3D printer really create strong, useful steel components? The response is a resounding yes! Fail to remember the plastic trinkets. Metal 3D printing is here, building a revolution in exactly how we layout and manufacture complex, high-strength elements. This isn’t sci-fi. It’s sophisticated production taking place today. Let’s dive into the remarkable reality of printing steel.

1. Just What is Metal 3D Printing? .

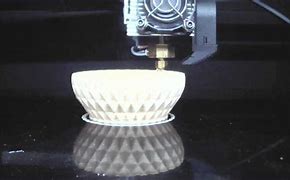

Steel 3D printing refers to advanced manufacturing procedures that build solid steel things layer by layer. This contrasts greatly with the common plastic-extruding desktop computer printers lots of know. Steel 3D printing doesn’t thaw plastic filament. Instead, it makes use of effective power sources like lasers or electron light beams. These specifically fuse fine steel powder or deposit molten metal cord. The result is a totally thick metal component. Consider it as ultra-precise, digitally managed welding developing a things from scratch. This modern technology opens geometries impossible with typical machining. It creates complicated interior networks, light-weight latticework frameworks, and integrated assemblies in a single print. Common metals used include stainless-steel, titanium, aluminum, nickel alloys, and even rare-earth elements like gold. The bottom line is the final component is actual, usable steel.

2. Why Pick Steel 3D Printing? .

So why use metal 3D printing rather than standard methods like casting or machining? The advantages are substantial. First, it offers amazing design flexibility. Complex forms, interior features, and natural geometries are possible. These designs are usually also tough or pricey to make or else. Second, it makes it possible for lightweighting. Components can be developed with elaborate interior latticeworks or hollow sections. This lowers weight without compromising strength. This is important in aerospace and auto applications. Third, it reduces waste. Traditional machining typically starts with a big block of steel. Much material obtains remove. Steel 3D printing includes material just where needed. This reduces scrap. Fourth, it enables part debt consolidation. Multiple parts can be developed and published as a single item. This gets rid of assembly steps and prospective failing points. Fifth, it accelerates prototyping and manufacturing for complex components. Developing a complex steel prototype commonly can take weeks. Metal 3D printing may do it in days. Lastly, it sustains personalization. Making unique, one-off steel parts ends up being financially feasible.

3. How Do Printers Create Metal Things? .

The magic happens via several sophisticated techniques. One of the most typical approaches are Powder Bed Fusion (PBF) and Directed Energy Deposition (DED). In Powder Bed Fusion, a slim layer of fine metal powder spreads out throughout a develop system. A high-power laser or electron beam scans the powder bed. It selectively thaws and integrates the powder bits together. This complies with the cross-section of the component for that layer. The platform reduces a little. Another layer of powder spreads. The process repeats. Layer by layer, the part forms inside a bed of powder. The unfused powder sustains the framework throughout printing. After cooling down, the part is gotten rid of from the powder. Excess powder is wiped. Assistance frameworks are removed. Usually, heat therapy complies with to soothe stress and anxieties and enhance residential or commercial properties. Directed Energy Deposition functions differently. A nozzle deposits steel powder or cord. A focused power source (laser, electron beam of light, or plasma arc) thaws the product as it’s transferred. This builds up material layer by layer. DED excels at adding material to existing components or developing big frameworks. Both techniques require specialized, industrial-grade equipment. They operate in controlled settings, frequently with inert gases to prevent oxidation. Security is paramount as a result of great powders and powerful energy resources.

4. Where is Steel 3D Printing Beaming? (Applications) .

Metal 3D printing is transforming industries. Its unique capacities fix real-world problems. In aerospace, it develops lightweight, high-strength components. Believe complicated gas nozzles, wind turbine blades, and structural braces. Weight cost savings straight equate to fuel efficiency. The medical field accepts it for biocompatible implants. Titanium hip mugs, spinal cages, and cranial plates can be custom-made for a patient’s anatomy. This improves fit and recovery. Oral laboratories use it for crowns, bridges, and frameworks. The vehicle industry leverages it for high-performance parts. Personalized intake manifolds, light-weight suspension parts, and warmth exchangers take advantage of optimized layouts. Tooling and production gain advantages too. Conformal cooling channels inside shot mold and mildews can be printed. These channels comply with the mold and mildew’s contour. This cools plastic parts faster and more equally. It decreases cycle times and improves part quality. The energy industry uses it for facility generator parts and heat-resistant components. Even precious jewelry developers use it to create detailed rare-earth element items difficult to cast. The applications maintain expanding as the technology matures.

5. Metal 3D Printing Frequently Asked Questions: Your Burning Questions Addressed .

Many questions surround this innovation. Let’s take on some usual ones.

Can I do this with my home FDM printer? No. Desktop computer plastic printers utilize various innovation. They can not handle the heats or products required for metal. Metal 3D printing requires costly, industrial devices and stringent safety procedures.

Is the published steel solid? Yes. Parts produced by metal 3D printing attain thickness and mechanical properties comparable to, and in some cases surpassing, traditionally produced parts. Post-processing like warm treatment more boosts stamina and toughness.

Just how expensive is it? Steel 3D printing is significantly extra costly than plastic printing. Costs consist of high maker costs, expensive steel powders, specialized drivers, and post-processing. It’s justified for complex, high-value components where its advantages outweigh the price.

What about surface area coating? As-printed metal parts usually have a rougher surface finish than machined components. Post-processing techniques like machining, brightening, or grain blasting are commonly used to accomplish the desired smoothness.

Is it secure? Industrial steel 3D printing calls for rigorous precaution. Managing great metal powders demands warn to stay clear of breathing or surge threats. Effective lasers and electron beams require protective enclosures and safety and security training. Operators should follow stringent methods.

What steels can be published? A vast array is possible. Common ones include stainless-steels (316L, 17-4 PH), titanium alloys (Ti6Al4V), light weight aluminum alloys (AlSi10Mg), nickel-based superalloys (Inconel 625, 718), cobalt-chrome, and tool steels. Research remains to increase product alternatives.

(can a 3d printer print metal?)

Exactly how large can the parts be? Develop quantity depends upon the certain machine. Industrial printers can generate parts ranging from little dental implants to huge aerospace components numerous feet long. Larger parts normally call for DED innovation.