Discover a professional 3D printing powder supplier

Can Your 3D Printer Really Print Metal?

(can any 3d printers print metal?)

The world of 3D printing is amazing. We see printers making plastic toys, tools, and even parts for machines. But metal? Can those desktop machines sitting on workbenches actually print with metal? The short answer is mostly no, but the full story is much more interesting. Let’s dig into the metal side of 3D printing.

1. What are metal 3D printers?

Metal 3D printing is real. It’s a powerful manufacturing technology. It doesn’t work like your standard plastic printer. Forget about squeezing melted plastic through a nozzle. Printing metal requires serious power and specialized machines.

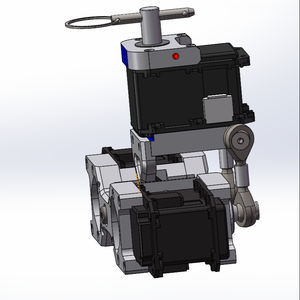

These aren’t the printers you buy for home projects. Metal printers are industrial-grade equipment. They are large, often expensive, and need special handling. They operate inside sealed chambers. These chambers are filled with inert gas or operate under a vacuum. This prevents the metal from reacting with oxygen during printing.

There are a few main ways to print metal. One common method uses a high-powered laser. This laser fuses tiny particles of metal powder together, layer by layer. Another method uses a binder. The binder glues metal powder particles. Later, heat treatment turns this green part into solid metal. Think of it as advanced sintering.

So, metal 3D printers exist. They are complex machines designed for factories and labs. Your average desktop FDM printer uses plastic filament. It simply cannot handle metal powder or the intense heat needed.

2. Why print metal?

Why go through all this trouble? Why not just machine metal parts? Metal 3D printing offers unique advantages. It unlocks new possibilities in design and manufacturing.

Complexity is free. Traditional manufacturing struggles with intricate shapes. Think of internal channels, hollow structures, or organic forms. Machining these can be impossible or very costly. 3D printing builds them layer by layer. It easily creates these complex geometries.

Weight reduction is crucial in many industries. Aerospace and automotive need strong but light parts. Metal printing allows engineers to design optimized structures. They can use lattices and thin walls. This cuts weight without sacrificing strength.

Consolidation is another benefit. An assembly of multiple parts can often be redesigned. It becomes a single, printed component. This reduces assembly time. It can also eliminate potential failure points.

Customization thrives with metal printing. Making unique metal parts is expensive with traditional methods. Printing allows for cost-effective production of bespoke items. This is great for medical implants or specialized tooling.

Speed for prototypes matters. Getting a metal prototype machined takes time. Printing can be faster for complex parts. It offers a quicker turnaround for testing designs.

3. How do metal printers work?

The process is fascinating. It starts digitally, just like plastic printing. A 3D model is sliced into thin layers. This digital file guides the printer.

The most common industrial method is Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). A thin layer of fine metal powder is spread across a build platform. A powerful laser beam scans the layer. It selectively melts the powder particles according to the sliced design. Where the laser hits, the powder fuses into solid metal. The platform lowers slightly. Another layer of powder is spread. The laser melts this new layer. It also bonds it to the layer below. This repeats until the entire part is built, buried in unused powder.

Another method is Binder Jetting. Here, a print head deposits a liquid binding agent onto a layer of metal powder. The binder glues the powder particles together in the desired shape. This creates a fragile “green” part. After printing, the green part undergoes a process called sintering. It’s heated in a furnace. The binder burns away. The metal particles fuse together into a solid piece. Sometimes, additional molten metal is infiltrated to fill gaps.

Metal Jet systems are newer. They work somewhat like inkjet printing. Tiny droplets of molten metal are deposited precisely to build the part. This method shows promise for higher speeds.

After printing, parts usually need finishing. They are removed from the powder cake. Support structures are cut away. Parts might be heat-treated for better strength. Surface finishing like sandblasting or machining is common.

4. Where are metal prints used?

Metal 3D printing is making a big impact across industries. It’s no longer just a lab curiosity.

Aerospace and aviation rely on it. These sectors need strong, lightweight components. Engine parts, turbine blades, brackets, and fuel nozzles are printed. GE Aviation prints thousands of fuel nozzles for jet engines. This reduces part count and weight significantly.

The medical field benefits greatly. Customization is key here. Surgeons use patient-specific models for planning. More importantly, biocompatible titanium is printed into implants. Hip joints, spinal cages, and cranial plates fit patients perfectly. Dental labs print crowns and bridges from cobalt-chrome alloys.

Automotive companies use it too. It’s great for prototyping new engine parts quickly. High-performance cars use printed components for weight savings. Custom tooling for assembly lines is also printed.

Energy sector applications are growing. Turbine components for power generation are printed. Oil and gas exploration uses printed parts that withstand harsh conditions. Heat exchangers with complex internal designs are possible.

Even consumer goods see some use. High-end watches might have printed metal cases. Some luxury brands offer customized metal jewelry printed to order. Industrial designers use printed metal prototypes for product development.

5. Metal printing FAQs

Let’s tackle some common questions about metal printing.

Can I put metal filament in my regular printer? No. Some companies sell metal-filled plastic filaments. These contain tiny metal particles mixed into plastic. You print them like regular PLA or ABS. After printing, you heat treat the part. The plastic burns away. The metal particles sinter together. The result is a metal part, but it’s porous and not as strong as truly printed metal. Your desktop printer still prints plastic.

How strong are printed metal parts? Properly printed and processed parts can be very strong. Their strength approaches, and sometimes matches, traditionally manufactured metal. It depends on the material, the printing process, and the post-processing.

What metals can be printed? Many! Common choices include titanium alloys (great for medical and aerospace), stainless steels, tool steels, nickel alloys (like Inconel for high heat), aluminum alloys, and cobalt-chrome. Copper printing is also advancing.

Is it expensive? Yes, metal printing is generally expensive. The machines cost hundreds of thousands of dollars. The metal powder itself is costly. Post-processing adds more expense. It’s best suited for high-value parts where its benefits justify the cost.

What about safety? Metal powder handling requires caution. Fine metal powders can be hazardous if inhaled. Printing often involves powerful lasers and high temperatures. Industrial facilities have strict safety protocols. This isn’t a hobbyist activity yet.

(can any 3d printers print metal?)

Metal 3D printing is a game-changer for manufacturing. It opens doors to new designs and applications. While your desktop printer sticks to plastic, the world of metal printing is forging ahead.