Discover a professional 3D printing powder supplier

**Metal Magic: Is 3D Printing Metal Real?**

(can you 3d print metal?)

So you saw that cool plastic toy printed on a 3D printer. Maybe you even made one yourself. It got you thinking. What about tougher stuff? What about metal? Can those machines really print things out of solid metal? The answer isn’t just yes. It’s a resounding “Yes, and it’s kind of amazing.”

Forget plastic trinkets for a moment. Picture this: complex jet engine parts, custom medical implants shaped perfectly for a patient’s bone, or lightweight car components impossible to make any other way. This is the reality of metal 3D printing. It sounds like science fiction, but factories and labs are doing it right now.

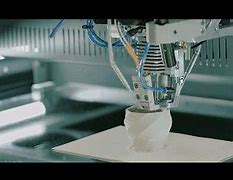

How does it work? It’s not like squirting molten metal like a glue gun. That would be messy and dangerous. Instead, most metal printers use super powerful lasers or electron beams. Think of them as incredibly precise, super-hot torches. They work inside a sealed chamber filled with an inert gas, like argon, to stop the metal from burning.

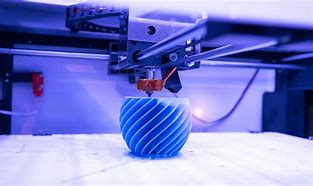

Here’s the basic idea. A thin layer of super-fine metal powder, finer than sand, gets spread across a build plate. This powder could be titanium, stainless steel, aluminum, nickel alloys, even gold. Then, the laser beam zaps across the powder bed. It follows a digital blueprint, melting the powder only where the final object needs to be solid. The heat is intense. It melts the tiny grains of powder instantly, fusing them together into a solid speck of metal. The build plate lowers slightly. Another layer of powder spreads on top. The laser zaps again, melting this new powder and welding it firmly to the layer below. This happens over and over, layer by layer, until the whole metal object is built up from nothing but powder and light.

This method has a fancy name: Powder Bed Fusion. It’s the most common way to 3D print metal. Other methods exist, like squirting a paste loaded with metal particles and then baking it, or using a welding arc to build up layers. Powder Bed Fusion gives the strongest, densest results, like solid metal.

Why bother? Why not just machine metal or cast it the old way? Metal 3D printing unlocks designs traditional methods simply cannot do. Imagine parts with intricate internal channels for cooling fluids, shapes with complex curves and lattices that are super strong but incredibly lightweight, or one-off custom parts made quickly without expensive molds. It lets engineers dream up wild new shapes and then actually make them. It reduces waste too. You use only the metal powder needed for the part, not big blocks you carve away.

You won’t find a metal printer in most homes yet. These machines are expensive, big, and need careful handling. The powder is hazardous, needing special air filtration. The process requires expert knowledge. But the results are game-changing. Aerospace companies use it for lighter, stronger plane parts. Doctors use it for personalized implants. Car makers experiment with it for high-performance components. Artists even create stunning metal sculptures with it.

(can you 3d print metal?)

Metal 3D printing is real. It’s transforming how we make things. It turns impossible designs into solid metal reality. It’s not magic, but the results sure feel like it.