Discover a professional 3D printing powder supplier

Can You 3D Publish Steel? The Surprising Truth Behind Modern Manufacturing Magic

(can you 3d print metal objects)

You’ve seen 3D printers make plastic playthings, phone instances, also prosthetic arm or legs. But what concerning metal? Can a machine actually “print” something as tough as steel or titanium? The response is yes– and it’s means cooler than you assume. Allow’s break down how this sci-fi-sounding technology actually works.

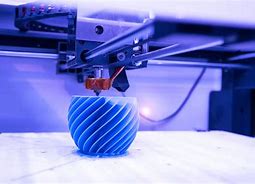

First, forget the plastic-spitting printers you have actually seen online. Steel 3D printing isn’t concerning thawing down cable or pressing goo from a nozzle. Rather, it utilizes lasers, powdered steel, and a whole lot of precision. The most common approach is called “straight metal laser sintering” (DMLS). Envision a super-focused laser beam zapping tiny particles of metal powder, integrating them layer by layer right into solid forms. It resembles constructing a sandcastle, however as opposed to sand and water, you’ve got stainless steel and lasers.

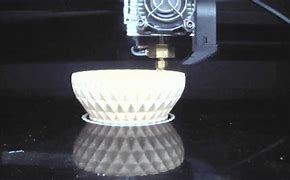

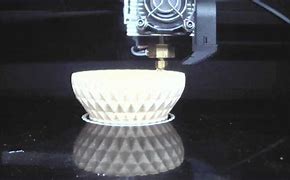

But just how does it actually occur? A printer spreads a slim layer of metal powder onto a construct system. The laser then traces a pattern, thawing the powder right into a strong piece of your item. The system decreases somewhat, one more layer of powder gets included, and the laser repeats the procedure. Over hours– or days– your metal component grows from all-time low up. The remaining powder gets recycled, making it less inefficient than traditional approaches that sculpt metal blocks right into form.

Not all steel printing uses lasers, however. An additional prominent method, “binder jetting,” works like a state-of-the-art glue weapon. The printer sprays a liquid binder onto layers of metal powder, sticking particles with each other like a tiny problem. Once the entire object is “glued,” it’s warmed in a furnace to burn off the binder and fuse the metal. This technique is more affordable and quicker however frequently requires additional completing steps to make the steel strong enough for heavy-duty use.

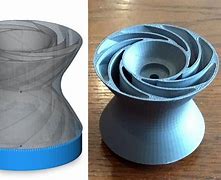

So why bother with metal 3D printing? For starters, it lets engineers produce forms that are difficult with old-school techniques. Believe hollow structures, detailed lattices, or parts with surprise networks for cooling down or airflow. Aerospace firms use it to make lighter rocket parts. Physicians utilize it for custom bone implants that fit individuals completely. Even carmakers are evaluating 3D-printed steel components to enhance efficiency and cut expenses.

However it’s not all smooth sailing. Metal printers are pricey– some cost greater than a residence. The products aren’t cheap either. A kg of titanium powder can establish you back thousands of bucks. Printing is additionally sluggish. A fist-sized component could take 20 hours. Bigger things? Days. Plus, not every steel functions. Usual options include stainless-steel, aluminum, and titanium, yet softer metals like copper or gold are trickier to print without warping.

One more difficulty is stamina. While 3D-printed steel components can be strong, they’re not always as reputable as built or machined ones. Tiny voids or blemishes from the printing procedure can damage the structure. That’s why vital components like jet engine elements undertake strenuous testing prior to they’re approved for usage.

Still, the tech is evolving quickly. Business are explore hybrid printers that integrate 3D printing with machining for smoother coatings. Researchers are establishing new steel alloys developed particularly for printing. Rates are dropping, also. What used to be a device for labs and Fortune 500 firms is currently sneaking right into smaller sized workshops.

(can you 3d print metal objects)

So yes, you can 3D print steel– and it’s improving every little thing from health centers to racecars. But it’s not magic. It’s scientific research, patience, and a great deal of experimentation. Whether you’re an enthusiast or an engineer, one thing’s clear: the future of making points is obtaining hotter, shinier, and means a lot more laser-filled.