Discover a professional 3D printing powder supplier

** Metal Magic: Can Stabilizers Supercharge Your 3D Prints? **.

(can you add metal stabilizers to 3d printing)

Ever published something cool, just to enjoy it warp like a depressing banana? Or maybe it snapped method as well conveniently? We all want stronger, harder, extra trusted 3D prints. This got me thinking of something wild: metal stabilizers. Yeah, steel! Can we actually mix tiny bits of steel right into our plastic filament? The idea seems remarkable right? Making our prints act a little bit much more like metal without needing an expensive steel printer. Allow’s dig in.

Initially, what are metal stabilizers anyway? Consider them as super-tiny metal bits. Super little, like dust and even smaller sized. The strategy? Blend these steel little bits straight into the plastic filament before it also goes into your printer. Or possibly blend them right into the liquid material if you make use of a resin printer. The objective is basic: provide the plastic some added muscle.

Why bother? Plastic is terrific for many points. But in some cases you need a lot more. Metal bits could make prints a lot stronger. They might make them handle heat much better, so less bending. Maybe they make parts much heavier and really feel more solid, like genuine steel. For things like machine components or tools, this extra stamina is a large deal. It sounds like an easy upgrade with huge possibility.

However here’s the catch. It’s not nearly discarding steel dust right into plastic. Printing with this mix is difficult. Photo this: your warm nozzle attempting to press out plastic full of tiny steel chunks. It might obstruct. Terribly. Metal little bits might stick inside the nozzle, causing jams. Not enjoyable. Additionally, the metal and plastic need to blend perfectly. If they do not, the steel bits may clump. This makes weak spots in your print. You would certainly obtain a part that looks solid but breaks easily where the clumps are.

Then there’s the nozzle itself. Criterion brass or stainless-steel nozzles? They may wear extremely fast massaging against difficult steel bits. Think about sandpaper grinding away inside. You would certainly need harder nozzles, possibly set steel or even ruby-tipped ones. That adds price. The printing temperature might additionally require altering. Steel performs warm in different ways than plastic. Obtaining the temperature level just right is critical.

So, can you actually do it now? Well, yes and no. You can’t just order metal powder off the shelf and mix it with your routine PLA filament. It will not work well. However business * are * making special composite filaments. These filaments already have actually steel particles mixed in. They design them to move much better via printers. You usually require those tougher nozzles we discussed. These filaments exist. You can acquire them. They make prints that look and feel a bit metallic. They are much heavier. They could be a little bit more powerful than ordinary plastic.

The results? Impressive, yet not magic. Your print will not all of a sudden be as strong as strong steel. It’s still mainly plastic. However it * is * stronger than normal filament. It has that great steel look and weight. For numerous enthusiasts and some professionals, this is a great alternative. It links the space between plastic and metal printing without the insane expense.

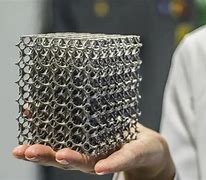

The actual cutting edge? Committed steel 3D printing. This makes use of lasers or binders to fuse steel powder together. It makes * real * strong metal parts. This technology is remarkable however intricate and costly. It’s a various world from your desktop FDM printer.

(can you add metal stabilizers to 3d printing)

Mixing metal stabilizers directly right into typical filament at home? That’s still a big obstacle. The clogging risk is high. Obtaining an excellent mix is hard. Yet those pre-made metal composite filaments? They are a real, sensible remedy today. They let you include a dosage of metal durability to your prints. You get more powerful parts, much less bending, which satisfying metal heft. It’s not sci-fi. It’s happening today on workbenches everywhere.