Discover a professional 3D printing powder supplier

Unlocking the Truth: Metal’s Role in 3D Printed Firearms

(do 3d printed guns have any metal parts)

What Exactly Are 3D Printed Guns?

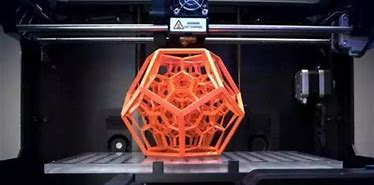

People hear “3D printed gun” and picture something straight out of science fiction. Maybe a weapon made entirely from colorful plastic, popping out of a machine ready to fire. But the reality is much more complex. At its core, a 3D printed gun refers to a firearm where some key parts are created using additive manufacturing, commonly known as 3D printing. This process builds objects layer by layer, typically from plastic filaments. It offers a way to create complex shapes that might be difficult or expensive to make otherwise. However, calling them “plastic guns” is a big oversimplification. These aren’t toys you can assemble after printing a single file. Understanding what makes them tick requires looking under the hood. Most designs aren’t complete weapons fresh off the printer. Often, the printed parts form the frame or receiver – the body that holds everything else together. Think of it like the chassis of a car. The engine, wheels, and other critical components still need to be added. So, while 3D printing plays a role, it’s usually just one part of the puzzle. The printed pieces provide structure, but they rarely handle the intense forces of firing a bullet alone. That job usually falls to more traditional materials. The term covers a spectrum, from simple single-shot devices to more complex designs mimicking commercial firearms. The level of printing involved varies greatly.

Why Metal Parts Remain Essential (For Now)

Plastic is amazing for many things. It’s lightweight, moldable, and relatively cheap. But firing a gun creates extreme pressures and heat. When a bullet is fired, the explosion inside the chamber pushes the bullet forward and also slams the bolt or firing mechanism backward. This generates a huge amount of force. Most common plastics used in 3D printing, like PLA or ABS, simply aren’t strong enough to withstand this repeated stress for long. They can crack, warp, or even shatter catastrophically. Metal parts, like the barrel, bolt, firing pin, and springs, are crucial because they can handle these forces reliably. The barrel guides the bullet and contains the explosive pressure. It needs to be incredibly tough. A plastic barrel would likely fail instantly, possibly injuring the user. Similarly, the bolt slams back and forth with significant energy. Plastic bolts often break after just a few shots. Springs, needed to reset the firing mechanism, lose their tension quickly if made from plastic. Using metal for these high-stress components is about safety and functionality. A gun that explodes in your hand is useless. Metal provides the necessary durability and strength that plastic currently lacks. While researchers explore stronger printed materials, metal remains the practical choice for critical parts today. It’s the difference between something that works once and something that works consistently.

How 3D Printed Guns Combine Plastic and Metal

So how do these hybrid weapons actually come together? The process usually starts with a digital design file. Someone designs the parts intended for printing – often the lower receiver or frame – using CAD software. This file is then sent to a 3D printer. The printer melts plastic filament and deposits it layer by layer to build the shape. Once printed, these plastic parts might need some finishing. This could involve sanding rough edges, drilling holes more precisely, or cleaning off support material used during printing. Now comes the key part: assembly. The printed plastic frame or receiver acts as the foundation. Into this foundation, the user installs pre-made metal components. These are typically standard firearm parts you might buy separately or salvage from existing guns. Common metal parts include the barrel, bolt carrier group (for rifles), firing pin, hammer, springs, and sometimes the trigger assembly itself. For example, in designs based on the AR-15 platform, the printed part is often just the lower receiver. The user then buys or sources a complete metal upper receiver assembly (which houses the barrel and bolt) and installs it onto the printed lower. The plastic part holds the metal parts in the right positions. The metal parts handle the explosive forces and the actual firing sequence. It’s a marriage of new manufacturing tech with old-school metal components. The printer makes the body; the metal provides the muscle.

Real-World Applications and Legal Quagmires

It’s tempting to think about 3D printed guns only in dramatic contexts, like spies or criminals. The reality is more nuanced. Hobbyists and gun enthusiasts are often drawn to the technical challenge. Building something yourself is appealing. Printing parts allows for customization that might not be possible with commercial firearms. Some see it as a way to exercise perceived rights, particularly regarding homemade firearms. However, the legality is a major minefield. Laws vary wildly across different countries and even states within the US. In many places, manufacturing a firearm, even for personal use, requires licenses or is outright illegal. Laws like the Undetectable Firearms Act in the US mandate that guns must contain enough metal to be detectable by security scanners. This often forces builders to include metal parts purely for compliance. There are also significant safety concerns. Homemade guns, printed or not, carry risks if not built correctly. A poorly constructed firearm can be extremely dangerous to the user. Law enforcement agencies worry about untraceable weapons entering circulation. The technology itself is neutral. But its application touches on complex issues of regulation, public safety, and individual freedoms. It’s a topic sparking heated debates worldwide. Understanding the laws in your specific location is absolutely critical before even considering such a project. Ignorance is not a defense.

FAQs: Burning Questions Answered

(do 3d printed guns have any metal parts)

Let’s tackle some common questions head-on. Are 3D printed guns completely plastic? No. Almost all functional designs require metal parts for critical components like the barrel, bolt, and firing pin. Plastic alone can’t handle the stress. Are they undetectable? Not if they follow laws like the US Undetectable Firearms Act. These laws require enough metal to trigger metal detectors, usually achieved by adding a metal block or using metal parts. Can you buy them online? Finding complete working guns is unlikely on mainstream platforms. You might find digital design files, but manufacturing the gun falls to the individual. Are they reliable? It depends heavily on the design, materials used, and build quality. Many printed guns are single-shot or have limited reliability compared to commercial firearms. They can be dangerous if they fail. Are they legal? This is the biggest question. Laws are complex and vary. In many places, manufacturing firearms without a license is illegal. Laws regarding unserialized or “ghost” guns are changing rapidly. Always consult current, local laws. The technology evolves, and so do the regulations. It’s a constantly shifting landscape. Safety is paramount. These devices are not toys.