Discover a professional 3D printing powder supplier

The Steel Enigma: What’s Actually Inside Those 3D Printed Weapons? .

(do 3d printed guns have metal in them?)

We see photos online. Smooth, futuristic-looking guns relatively birthed from a printer. It sparks questions. One big one appears constantly: Do these plastic-looking weapons in fact have any kind of metal inside? The solution isn’t simple yes or no. It’s a mix of plastic resourcefulness and crucial steel components. Allow’s fracture open the misconception and see what truly makes these devices tick.

1. What Components Actually Contain Metal? .

Neglect the sci-fi desire for a completely plastic gun shooting bullets. Reasonably, functional 3D published weapons rely greatly on metal for critical parts. Think about what a gun has to do. It has an explosion. It channels extreme pressure. It strikes a guide with sufficient energy to stir up. Plastic alone typically stops working at these work under firing stress.

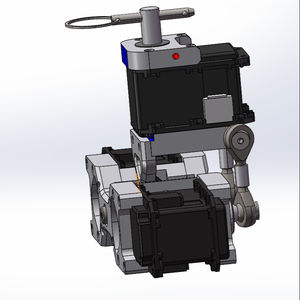

The essential metal parts are typically called “non-printable elements” or “regulated components.” These are the little bits you can not conveniently make at home with a conventional 3D printer. The barrel is a big one. The intense pressure and warm from firing a bullet would certainly damage most published plastics promptly. A metal barrel liner or sleeve is usually required. The chamber, where the cartridge blows up, likewise requires metal toughness.

Then there’s the firing pin. This small item needs to hit the guide difficult and specifically. Plastic is as well soft, also weak. A solidified steel firing pin is essential. Springs are another steel must-have. The hammer springtime, recoil spring, trigger spring– they all need the flexibility and strength just steel gives. Finally, the screw or breechblock, which secures the chamber and deals with recoil, usually incorporates metal inserts or is totally metal for reliability. So indeed, considerable metal lurks inside the plastic shell.

2. Why Steel Parts Are Non-Negotiable .

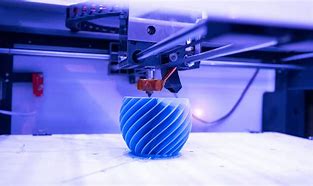

Plastic printers are incredible. They develop complex shapes from electronic layouts. But physics sets tough restrictions. When a basic bullet fires, pressures inside the chamber can go beyond 50,000 PSI. Temperatures soar. No typical 3D printing plastic like PLA or abdominal can withstand that repetitively. They would melt, fracture, or ruin violently. Steel handles this atmosphere.

Strength is the first reason. Steel alloys supply incredible tensile stamina and warmth resistance. They contain the explosion safely. Longevity is next. A plastic firing pin might work when, perhaps two times. Then it flaws or damages. A set steel pin lasts. Dependability issues. Springs made of springtime steel offer constant force shot after shot. Plastic springtimes just don’t function efficiently for this purpose.

Security is paramount. A plastic barrel failing under pressure resembles an explosive taking off in your hands. Steel elements protect against catastrophic failing. They make certain the power decreases the barrel, thrusting the bullet, not damaging the weapon and harming the user. While some unique, high-strength polymers exist, they are uncommon, pricey, and not typically used in home-printed firearms. Common sense and fundamental design need metal for these critical, high-stress jobs.

3. Just How Contractors Integrate Plastic and Metal .

Producing a functional 3D published weapon isn’t just striking “print.” It’s a setting up procedure. Think about the published plastic components as the frame, the real estate, the framework. They wait with each other. Styles are shared online as electronic data (like STL or G-code). Customers download these and print the plastic parts on their desktop computer FDM (Molten Deposition Modeling) printers, layer by layer.

The metal components are sourced separately. This is the essential step. Contractors purchase these parts. Often they are conventional hardware shop products (like details nails utilized as firing pins in very early designs). More often, they are specialized weapon parts: barrel linings, shooting pins, springs, screws. These could originate from on-line retailers, gun part distributors, or perhaps be restored from existing firearms.

Setting up involves fitting these metal components into the printed plastic components. A published reduced receiver may house a metal trigger setting up and hammer. A published upper receiver could hold a steel barrel liner and screw. Screws, pins, and epoxy glue are frequently utilized to safeguard every little thing. The skill depends on exactly adhering to the layout instructions and making certain the metal components fit snugly and safely within the published structure. The printer makes the covering; the metal gives the working guts.

4. Practical Applications Beyond Hype .

The media usually focuses on the debatable side of 3D published guns. Yet the modern technology has broader, genuine uses. Enthusiasts and gunsmiths discover this room for testing and custom-made tasks. Printing one-of-a-kind holds, supplies, or non-critical accessories is preferred. These components see little stress and anxiety and add customization without needing metal.

Prototyping is one more crucial application. Guns makers use advanced industrial 3D printers (far more advanced than home models) to develop models swiftly and inexpensively. They examine type, fit, and feature before dedicating to costly steel tooling. This accelerates layout cycles considerably.

Educational usage exists too. Shut off versions or non-firing reproductions, typically completely plastic and safe, are printed for historic screens, training aids, or motion picture props. They provide a secure means to examine weapon mechanics. Some fanatics style and print specialized devices for gunsmithing– jigs, alignment devices, or cleansing help. These devices utilize the personalization power of printing without entailing functional gun components. The core innovation of additive production is effective; its application to guns is just one, extremely controlled, facet.

5. Burning Concerns Addressed .

Allow’s tackle some regular queries head-on:.

Can you really publish a entire weapon without metal? Technically, yes, for really basic styles shooting low-pressure ammo (like.22 rimfire) possibly one or two times. However it’s unbelievably dangerous, unreliable, and prohibited in the majority of locations. It’s not useful or secure. Metal parts are needed for anything appearing like a usable firearm.

Are the plastic parts legal? Laws vary hugely by nation and also by state or area. In lots of locations, publishing certain plastic parts (particularly frames or receivers legitimately categorized as the “weapon”) is unlawful without licenses. Having documents to print guns can also be illegal. Always understand your neighborhood legislations.

Do they appear on metal detectors? This depends totally on the amount and placement of steel. A weapon with a full metal barrel lining, bolt, and firing pin will likely trigger a detector. One with marginal metal (like simply a little firing pin) may not, but its functionality and safety are extremely doubtful. Do not count on this.

Are they as dependable as normal weapons? Generally, no. Home-printed firearms are frequently prototypes or pastime jobs. Product weak points, print flaws, and setting up variations make them less trustworthy and possibly more dangerous than readily made firearms developed to stringent requirements.

(do 3d printed guns have metal in them?)

Why is this innovation controversial? The major concern is the possibility for untraceable weapons (” ghost guns”) bypassing background checks and serial number policies. This raises significant police and public security issues. The modern technology itself is neutral; its application in weapons is greatly discussed and controlled.