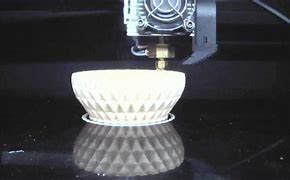

Discover a professional 3D printing powder supplier

** Plastic Pistols? The Steel Truth Concerning 3D Printed Weapons **.

(do 3d printed guns require metal)

The concept of a weapon bulging of a 3D printer sounds like sci-fi. You envision something made totally of plastic, possibly in your garage. It feels advanced and maybe a little terrifying. However just how actual is that picture? Can plastic alone really make a working weapon? The simple solution is no. Reality bites hard here.

Plastic thaws. It deforms. It breaks. Weapons deal with severe pressures. Think of firing a bullet. An explosion happens inside the chamber. Hot gases blow up out at unbelievable speeds. The pressure is huge. Plastic alone just can not handle that. It would certainly shatter or thaw on the very first shot. It might even harm the individual trying to utilize it.

So, what parts actually need steel? The barrel is a huge one. That’s the tube the bullet shoots with. It encounters the most popular temperatures and the greatest stress. Also solid plastics like ABS or nylon soften method as well quickly under that warm. Think of a pastel left in the sunlight. That barrel needs difficult metal to make it through. Steel is the typical option. A plastic barrel is basically ineffective and dangerous.

Successive is the shooting pin. This little piece is important. It smacks the rear of the bullet’s primer to ignite the gunpowder. That needs a sharp, hard factor. Plastic is too soft. It would warp or break immediately. It requires the hardness of metal to function accurately. Think about trying to poke a hole in cardboard with a sponge versus a nail. The steel nail wins each time.

After that there are springs. Weapons depend on springs for lots of things. Publications need springtimes to push bullets up. Activates demand springtimes to reset. Discharging pins typically need springs too. Springs need elasticity. They must stretch or compress and then break back flawlessly. Plastic does not have that springy top quality. It’s also brittle or as well saggy. Steel springs are important for the weapon to function more than once.

Lastly, we have the ammo itself. The bullet casing is almost always metal. It contains the eruptive gunpowder charge. Plastic cases exist, however they are experimental and rare. The case needs to seal the chamber during firing. It must endure the surge without rupturing. Steel does this work reliably. The actual bullet projectile, the component that flies out, is also often metal. Plastic bullets lack the weight and hardness to be efficient.

(do 3d printed guns require metal)

So, the imagine a pure plastic weapon is just that– a dream. While 3D printers can make many weapon components look real, the important little bits require steel. The barrel, the shooting pin, the springs, and the ammunition all count on steel’s toughness and warm resistance. Plastic deals with the shape, the frame, the grip, possibly the stock. Yet the parts that make the bang and manage the force? Those are stubbornly metallic. Constructing a practical firearm still indicates handling metal components. The plastic printer assists, yet it doesn’t change the metal completely.