Discover a professional 3D printing powder supplier

Is 3D Metal Printing Still Alive? Kicking or Collecting Dirt?

(do people stil use 3d metal printing)

Individuals see remarkable points online. Complex metal forms popping out of devices. Headlines shriek concerning making revolutions. Yet after that, you look around. Is anyone actually using this stuff? Is 3D steel printing just an amazing technique, or is it developing the future? Let’s dig in.

1. Exactly What is 3D Metal Printing? .

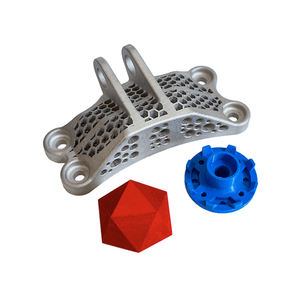

Forget those plastic playthings you could publish in the house. 3D metal printing is something else completely. It’s a method to construct strong metal parts, layer by layer, right from a computer system documents. No hammers. No molds. Think about it like a really accurate welder drawing in mid-air, or a printer utilizing metal dust and lasers instead of ink. The magic happens inside unique devices. They use effective lasers or electron light beams to thaw little fragments of steel powder, merging them together specifically where required. Layer after layer builds up till you have a total part. It’s manufacturing, yet done digitally. This modern technology has genuine names too, like Additive Manufacturing (AM) for steels, or particular kinds such as Direct Metal Laser Sintering (DMLS) or Careful Laser Melting (SLM). It’s complicated innovation striving.

2. Why Trouble with 3D Metal Printing? .

So why jump through these modern hoops? Why not just machine a block of steel like constantly? The reasons are strong. Initially, style liberty. Traditional methods frequently limit what forms you can make. Need complicated contours, inner networks, or hollow frameworks? 3D printing makes fun of those restrictions. It can make forms difficult differently. Second, it’s wonderful for complex, low-volume parts. Making a personalized clinical implant or a specialized aerospace brace? Publishing one may be less costly and faster than establishing traditional tooling. Third, it utilizes material intelligently. Instead of cutting away a lot of a metal block, printing adds material just where it’s required. Much less waste is great. Fourth, it can incorporate parts. As opposed to welding or bolting a number of pieces together, you can publish the entire setting up as one strong piece. That implies less powerlessness and much less assembly time. These benefits fix real problems for engineers and designers.

3. Just How Does 3D Metal Printing In Fact Work? .

The process appears like sci-fi, yet it’s real. Several methods exist, however 2 are common. The initial is Powder Bed Fusion. Visualize a slim layer of fine steel powder spread across a system. A super-focused laser or electron beam of light zaps particular places, melting the powder fragments with each other. The platform goes down somewhat. Another layer of powder spreads. The laser attracts once again, melting brand-new powder and bonding it to the layer below. This repeats hundreds or countless times up until the part is done. The unused powder sustains the component throughout printing and is reused later. The second major approach is Binder Jetting. Right here, a print head (like an inkjet printer) sprays small decreases of a fluid binder onto a layer of steel powder. The binder glues the powder fragments with each other in the preferred form. After building layer by layer, the part is still breakable. It enters into a stove for sintering– heating it to bond the metal bits properly. In some cases, added metal is instilled also. Both methods require mindful control and effective equipment.

4. Where is 3D Metal Printing Made Use Of Today? .

This technology isn’t sitting in a laboratory. It’s around functioning. Look at aerospace. Firms print light-weight, super-strong components for jet engines and spacecraft. Believe complex gas nozzles or turbine blades with inner cooling networks. The medical area loves it as well. Surgeons utilize patient-specific implants printed to flawlessly fit bone frameworks. Oral laboratories publish crowns and bridges. The auto market uses it for prototyping new layouts quickly and making high-performance customized parts for auto racing or deluxe autos. Even hefty markets such as oil and gas usage published parts for devices that endure severe problems. It’s turning up in making personalized fashion jewelry and thorough art pieces also. From life-saving implants to faster race autos, 3D steel printing is proving its worth across many areas. It addresses specific problems where traditional methods fail.

5. Frequently asked questions: Your Burning Concerns Answered .

Individuals constantly have questions regarding this tech. Below are the common ones:.

Q: Is it really solid? Like, actual metal solid? .

A: Yes. Printed metal components can be equally as strong, sometimes stronger, than traditionally made components. It relies on the steel made use of and the printing setups. They undergo the very same extensive screening.

Q: Just how much does it set you back? Is it only for gigantic firms? .

A: It can be expensive. The makers and materials set you back a lot. However it’s ending up being extra obtainable. Service bureaus allow smaller sized firms send styles out for printing without getting the equipment themselves. Expenses are dropping.

Q: Can I print anything I desire? .

A: Almost, however not rather. Design policies still use. You require supports for looming features throughout printing. Likewise, large parts might need special, large equipments. The liberty is significant, yet not limitless.

Q: What metals can be printed? .

A: Lots! Common ones include stainless steels, titanium alloys (terrific for medical and aerospace), aluminum alloys, nickel-based superalloys (for hot engine parts), and also rare-earth elements like silver and gold.

Q: Is the surface area coating good? .

A: Right off the printer, parts typically have a slightly rough surface. Assume great sandpaper. For lots of uses, this is fine. If an incredibly smooth surface is required, you can maker or polish it afterwards, similar to any various other steel component.

Q: For how long does it require to print something? .

(do people stil use 3d metal printing)

A: It depends. Small, straightforward parts could take hours. Large, complex ones could take days. It’s frequently quicker than making tooling for conventional production, particularly for one-offs or small batches.