Discover a professional 3D printing powder supplier

Is Your Steel 3D Publish Asking for a Hot Day? The Warm Treatment Lowdown .

(do you have to heat metal 3d printed parts?)

Steel parts fresh off the printer appearance impressive. They really feel strong. But looks can deceive. That shiny metal things could be hiding inner anxiety. It could be remarkably fragile. Typically, it requires a little extra love. It requires heat. Allow’s discover why home heating steel 3D published components isn’t just an option, it’s generally important.

1. What Are Steel 3D Printed Components? .

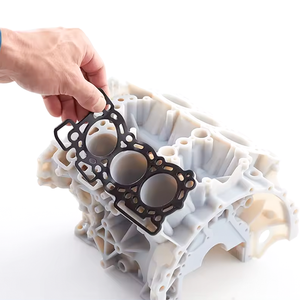

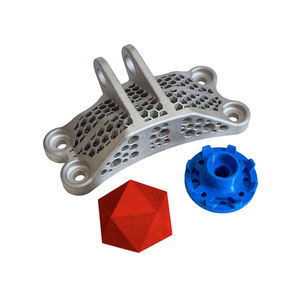

Metal 3D printing builds things layer by layer. Consider it like welding tiny dots of metal powder with each other utilizing a laser or electron light beam. Common approaches include Direct Steel Laser Sintering (DMLS) and Selective Laser Melting (SLM). Products vary from stainless-steel and titanium to light weight aluminum and unique superalloys. The printer develops complex shapes difficult with conventional approaches. Think complex cooling channels inside an engine part or light-weight aerospace braces. The process is powerful. However the intense, localized heating and rapid cooling create distinct difficulties inside the steel. The component comes out warm, but its internal framework is far from perfect. It’s like baking a cake also quick; the outside could look done, but the within is untidy.

2. Why Warmth Metal 3D Printed Parts? .

Heating, or warm treatment, solutions problems created during printing. The major factor is anxiety alleviation. The printing procedure subjects the steel to wild temperature level swings. Tiny areas thaw and cool extremely quick. This traps considerable inner stresses. Laid off, these stress and anxieties can create bending over time. Worse, they can make the component split unexpectedly. Heat treatment unwinds these locked-in tensions. Another large factor is enhancing mechanical residential properties. As-printed steel often has a non-ideal microstructure. It can be too tough and brittle. Managed heating modifications this interior framework. It can make the metal harder. It can make it stronger. It can enhance its ability to flex without breaking (ductility). For some alloys, heating is the only means to accomplish the needed toughness. It transforms the part from a vulnerable model into a trusted component.

3. How Do You Warm Metal 3D Printed Components? .

You don’t simply toss these parts in a cooking area stove. Precision is crucial. The most usual approach is heater heat therapy. The published components enter into a special, controlled furnace. The temperature climbs slowly to a specific factor. This factor depends entirely on the steel alloy. For stress relief, temperatures may be around 650-750 ° C for stainless-steel. Greater temperatures are made use of for full annealing or solidifying. The parts saturate at this temperature for hours. This offers time for the inner changes to occur. Then, cooling occurs gradually inside the heater. For parts requiring optimal stamina and absolutely no inner issues, Hot Isostatic Pushing (HIP) is made use of. HIP integrates high warm with enormous gas pressure from all sides. This stress squeezes inner voids shut. It likewise enhances the metal’s density. Both approaches call for cautious control. The exact dish (temperature, time, cooling down price) is essential. Get it incorrect, and the part can be destroyed.

4. Applications of Warmed Steel 3D Printed Components .

Where do these heat-treated parts radiate? Practically anywhere requiring high efficiency. Aerospace is a major user. Think turbine blades, fuel nozzles, and architectural brackets in aircrafts and rockets. These components encounter severe tension and temperature. Warmth treatment guarantees they won’t fail. The medical field relies upon them too. Implants like hip stems or back cages need extraordinary biocompatibility and toughness. Titanium components are often warmth dealt with to achieve this. The automotive industry uses them for high-performance engines and light-weight components. Warm therapy makes these components resilient sufficient. Even complex tooling benefits. Mold and mildews and dies made using 3D printing can incorporate air conditioning networks. Warm treatment hardens the surface. It makes the tool last longer under penalizing problems. Essentially, any application requiring solid, intricate, trusted metal components likely uses heat-treated 3D prints.

5. FAQs Regarding Heating Steel 3D Printed Components .

Is home heating constantly essential? Often, yes. For useful components needing toughness and dependability, avoiding warmth treatment is high-risk. Attractive items could escape without it, however also after that, anxiety might trigger issues later.

What happens if I avoid it? The component may warp unexpectedly. It could be much weaker or more fragile than anticipated. It may crack under load, specifically exhaustion tons. Its performance will certainly be unreliable.

Does it transform the part’s dimension? Yes, a little. Warmth treatment creates little dimensional changes. This is foreseeable. Good developers make up this shrinking or development in the initial part style. Accuracy parts could require machining after warmth therapy.

Can I warm deal with at home? Highly not suggested. Accomplishing the accurate, regulated temperature levels needed needs commercial devices. Cooking area stoves can’t reach or maintain these temperatures securely. Trying it could damage the component, the stove, or trigger a fire.

(do you have to heat metal 3d printed parts?)

Does it make the part weak? Usually the opposite! Correct warm treatment significantly increases toughness and strength. The goal is to maximize the material’s residential properties for its intended task. Particular processes like annealing may soften the steel deliberately, making it easier to device, yet this is controlled and valuable.