Discover a professional 3D printing powder supplier

Metal Magic: Have You Experienced 3D Printing’s Wildest Technique?

(have you ever seen 3d printing in metal?)

Metal 3D printing sounds like sci-fi. Envision building facility metal parts layer by layer straight from a digital data. Forget carving or casting. This is additive manufacturing at its most progressed. It’s improving just how we make points. This blog site explores this fascinating innovation.

1. What is Metal 3D Printing?

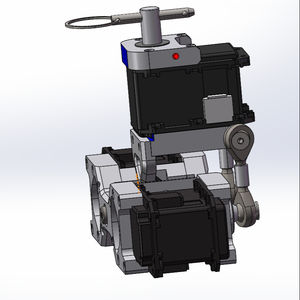

Metal 3D printing builds solid steel things. It uses electronic blueprints. Consider it like a really exact, sophisticated welding procedure. Rather than starting with a block of metal, it develops components by adding little amounts of product. Layer upon layer develops the last form. Numerous approaches exist. Some thaw metal powder with lasers. Others bind powder along with glue. Then warmth merges it. Another approach extrudes metal paste. Each strategy has pros and cons. But the core idea is the same. They create complicated metal parts straight. This prevents many typical production actions. It unlocks new design possibilities. Components can have intricate interior channels. Or shapes difficult to device. This is additive production for metal.

2. Why Pick Metal 3D Printing?

Why use steel 3D printing? It supplies special benefits. First, design liberty is huge. Facility geometries are easy. Think hollow structures inside solid components. Or natural shapes inspired by nature. These styles are frequently lighter and stronger. Second, it minimizes waste dramatically. Standard machining remove product. This leaves great deals of scrap. Metal printing makes use of only the material needed for the component. This saves material expenses. Third, it enables rapid prototyping and manufacturing. Designs transform quickly. New parts print fast. No need for expensive tooling or molds. 4th, it allows modification. Making unique parts is simple. Batch sizes of one are economical. Fifth, it combines several parts right into one. This streamlines assemblies. Fewer parts imply much less opportunity of failure. These advantages drive its fostering. Industries worth these capacities.

3. Just How Does Metal 3D Printing Work?

How does steel 3D printing really function? The major process is called Powder Bed Blend. A thin layer of fine steel powder spreads out throughout a develop system. A powerful laser or electron beam of light checks the powder bed. It complies with the cross-section of the part. The beam of light thaws or sinters the powder bits. They fuse together. The platform reduces a little. Another layer of powder spreads on the top. The laser checks once again. This melts the brand-new layer. It bonds to the layer listed below. This repeats hundreds or thousands of times. Layer by layer, the component expands inside the powder bed. When finished, the build chamber cools down. The excess powder is eliminated. The component is recovered. It often requires post-processing. This consists of eliminating support structures. Warm treatment enhances strength. Surface area finishing boosts look. Other approaches exist. Binder Jetting uses a fluid binder to adhesive powder bits. Then sintering integrates them. Directed Energy Deposition feeds metal cord or powder right into a thaw swimming pool produced by a laser. Steel Extrusion pushes metal-filled filament via a nozzle. Each approach matches various requirements.

4. Applications of Steel 3D Printing

Where is metal 3D printing utilized today? Its applications grow regularly. Aerospace and aviation like it. They print solid, lightweight parts. Wind turbine blades and fuel nozzles prevail. These components stand up to severe problems. Weight savings improve gas performance. The clinical area uses it extensively. Personalized implants fit people completely. Knee replacements and spinal implants advantage. Oral crowns and bridges are additionally printed. The automobile industry adopts it also. High-performance cars make use of published components. Prototyping brand-new engine elements is quicker. Custom-made tooling aids assembly line. Power markets use it. Oil and gas need sturdy components for severe settings. Power generation utilizes published wind turbine components. Consumer goods see applications. Premium watches make use of published cases. Jewelry developers create complex items. Even art and sculpture use this modern technology. Its reach increases daily.

5. Frequently Asked Questions About Metal 3D Printing

People often ask inquiries concerning metal 3D printing. Here are some usual ones.

Are metal published parts solid? Yes. Correctly published and processed parts are very solid. They satisfy or exceed standards for actors or created components. Material residential or commercial properties are superb.

Is it expensive? It can be expensive upfront. Machines and materials lug high rates. However, for intricate parts or low volumes, it commonly saves money overall. It eliminates tooling costs. It reduces product waste.

What metals can be printed? Numerous steels job. Typical ones include stainless-steel, titanium, light weight aluminum, and nickel alloys like Inconel. Copper and tool steels are additionally. New products arise regularly.

Is the surface area coating good? As-printed parts typically reveal layer lines. They call for ending up. Methods like machining, polishing, or blasting attain smooth surfaces. Some newer procedures supply far better surface high quality directly.

(have you ever seen 3d printing in metal?)

How large can published components be? Size depends on the device. Desktop units take care of small parts. Industrial printers build big parts. Some machines publish parts over a meter in size. Multiple parts can be printed together. Bigger systems are developed constantly.