Discover a professional 3D printing powder supplier

** Metal Magic: Exactly How Does 3D Printing Turn Dust into Durable Masterpieces? **.

(how do you 3d print metal)

Picture crafting a complicated steel object not with hammers or mold and mildews yet with lasers and powdered dust. This isn’t science fiction– it’s 3D printing for steel, a process that seems like alchemy for the modern-day age. Allow’s damage down exactly how this technology changes tiny steel bits right into every little thing from rocket parts to custom-made precious jewelry.

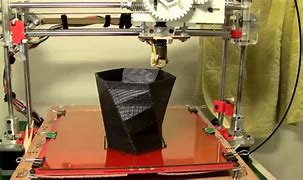

First, think of how regular 3D printing works. Plastic filaments thaw layer by layer to develop things. Metal 3D printing adheres to a similar concept yet swaps plastic for metal powder and warmth sources powerful sufficient to thaw or fuse metal. The goal coincides: construct things layer by layer from an electronic layout.

The procedure starts with a 3D version. Designers make use of software to slice the layout right into slim layers, like digital breadcrumbs. These layers assist the printer. Next, a fine steel powder– stainless-steel, titanium, or perhaps gold– is spread out evenly across a build system. Here’s where points get intense.

The majority of metal printers make use of lasers or electron beams to melt the powder. The laser zaps particular areas, complying with the electronic plan. Each dissolved layer cools into solid metal. After that, an additional layer of powder is added, and the laser repeats. With time, the things expands, buried in unused powder like a fossil in sand.

But melting metal isn’t the only method. Another technique, called binder jetting, works like a sophisticated adhesive weapon. The printer sprays a binding agent onto metal powder, sticking fragments together. The “eco-friendly” part is then warmed in a heater. The binder burns away, and the metal fragments fuse– a process called sintering. This develops a solid, thick item without complete melting.

Post-processing is crucial. Freshly published steel parts commonly look rough. They’re cleaned of excess powder, polished, or heat-treated to enhance strength. Some parts even enter into hydraulic presses to get rid of little spaces. The result? Steel parts as solid as those made by typical techniques.

Why choose 3D printing for metal? Conventional manufacturing often wastes product. Sculpting a part from a metal block leaves scraps. 3D printing utilizes just the powder needed, reducing waste. It additionally handles designs difficult for conventional devices. Believe hollow structures, complex latticeworks, or custom-made medical implants customized to a patient’s body.

Industries like this. Aerospace business publish light-weight generator blades with interior air conditioning channels. Medical professionals produce permeable bone implants that urge tissue growth. Carmakers model parts much faster. Even musicians explore steel prints, combining creativity with engineering.

Not all metals work the exact same. Some, like titanium, thaw efficiently. Others, like aluminum, need exact control to stay clear of problems. New alloys are being created simply for 3D printing, broadening what’s feasible.

The tech isn’t perfect. Metal printers cost millions, and sintering furnaces aren’t inexpensive. Handling fine metal powder requires safety and security gear– inhaling it is dangerous. Printing huge things takes hours or days. Engineers likewise fight deforming from unequal cooling.

Still, progression zooms ahead. Scientist test quicker lasers, less costly products, and crossbreed strategies. Startups trying out desktop computer steel printers, intending to make the tech accessible. Someday, 3D-printed steel could be as typical as plastic toys.

(how do you 3d print metal)

So next time you see a sleek metal gadget, keep in mind– it might have started as a stack of dust, formed not by hands however by light and code.