Discover a professional 3D printing powder supplier

Title: From Digital Dreams to Wrist Wonders: Your Metal Bracelet 3D Printing Adventure Starts Here!

(how do you 3d print metal bracelet)

Main Product Keywords: 3D print metal bracelet

1. What Exactly is 3D Printing a Metal Bracelet?

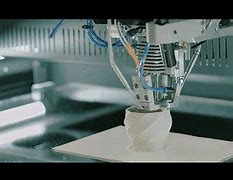

Forget everything you know about traditional jewelry making. 3D printing a metal bracelet isn’t about carving wax or soldering links. Think of it like a super-precise robot building your design layer by layer, but using real metal. It starts as a digital file on your computer, a detailed blueprint of your bracelet. This file gets sliced into super thin layers. The printer then reads these layers. It uses powerful lasers or electron beams to selectively melt fine metal powder, fusing it together exactly where your design dictates. Layer builds upon layer. Slowly, carefully, your bracelet emerges from a bed of unused powder. It’s not magic, it’s advanced manufacturing. It turns complex digital designs into tangible, wearable metal art. This process is often called Metal Additive Manufacturing (AM). It opens doors to shapes impossible to make any other way.

2. Why Choose 3D Printing for Your Metal Bracelet?

Why go high-tech for jewelry? The reasons are compelling. First, design freedom is huge. Imagine intricate lace patterns, impossible interlocking parts, or complex geometric shapes flowing around your wrist. Traditional methods struggle or fail with these. 3D printing handles them easily. Second, customization is king. Want a bracelet engraved with a unique pattern, your name, or a special date? It’s simple. The digital file is easily modified. Print one unique piece just for you. Third, it allows for complex functionality. Think integrated hinges, hidden clasps, or even elements designed to hold gemstones securely, all printed as one piece. Fourth, it can be surprisingly efficient for small batches or prototypes. No need for expensive molds. Just design it and print it. Finally, material choice matters. You aren’t limited to common jewelry metals. High-tech alloys like titanium, cobalt chrome, or specialized stainless steels become options. These offer unique colors, strength, and biocompatibility.

3. How Does 3D Printing a Metal Bracelet Actually Work?

Let’s break down the journey from screen to wrist. Step one is design. You create a detailed 3D model using CAD software. This model must be watertight, meaning no gaps or errors. Step two is preparation. Special software slices the model into ultra-thin horizontal layers, like digital blueprints for the printer. Step three is printing. The printer chamber fills with a thin layer of fine metal powder. A high-power laser or electron beam scans across the powder. It melts and fuses the powder particles exactly following the first slice of your design. The build platform lowers slightly. A new layer of powder spreads over the previous one. The laser scans again, melting this new powder onto the solidified layer below. This repeats hundreds or thousands of times. Step four is cooling. Once printing finishes, the entire chamber, filled with powder and your buried bracelet, cools down slowly. This prevents stress. Step five is post-processing. Workers carefully dig out the bracelet from the unused powder. Supports (temporary structures holding the design during printing) get removed. The bracelet undergoes finishing: sandblasting, polishing, maybe heat treatment for extra strength. Finally, it’s cleaned and inspected.

4. Cool Applications: Beyond Just Pretty Wrist Candy

3D printed metal bracelets aren’t just fashion statements. Their unique capabilities unlock fascinating uses. High-fashion designers love them. They create avant-garde pieces with impossible geometries, pushing artistic boundaries. Medical fields find value too. Custom-fitted bracelets could monitor health signals or deliver medication. Some designs integrate sensors discreetly. Prosthetics benefit greatly. A bracelet could be part of a larger prosthetic limb interface, tailored perfectly for comfort and function. Athletes might use specialized bracelets. These could track performance data or provide targeted support without restricting movement. The military explores durable, functional bracelets. These could carry identification, tools, or communication devices. Collectors seek limited edition art pieces. Artists leverage the technology for unique sculptures worn on the wrist. The blend of technology, art, and personalization creates endless potential.

5. FAQs: Your Metal 3D Printed Bracelet Questions Answered

People always have questions about this futuristic jewelry. Here are the common ones:

Is it strong enough? Absolutely. Properly printed and finished metal bracelets are very strong. They match or exceed the strength of traditionally made pieces. Material choice matters, but metals like titanium or stainless steel are robust.

How much does it cost? Costs vary. Simple designs in common metals start around $100-$300. Complex designs, larger sizes, or premium metals (like titanium or gold alloys) cost more, easily reaching $500-$2000+. It’s often more expensive than mass-produced pieces but competitive with high-end custom work.

What metals can be used? Popular choices include Stainless Steel (316L is common), Titanium (lightweight, strong, hypoallergenic), Cobalt Chrome (hard, durable, used in dental/medical), and precious metals like Gold or Platinum alloys. Bronze and Aluminum are also options.

Is the surface smooth? Right out of the printer, the surface is rough. It looks sandy. Post-processing is key. Sandblasting gives a matte finish. Polishing creates a shiny, smooth surface. Textured finishes are also possible. The final feel is like any quality metal bracelet.

Can I get it in different colors? Metal color depends on the material. Stainless steel is silver-gray. Titanium can be naturally gray or anodized to vibrant blues, purples, golds. Gold is gold. You can’t change the base metal color drastically like plastic, but finishes and coatings offer some variety.

How long does it take? Printing itself can take several hours to over a day, depending on size and complexity. The whole process, including design, printing, cooling, post-processing, and finishing, often takes 1-3 weeks.

(how do you 3d print metal bracelet)

Is it safe for sensitive skin? Metals like Titanium and Surgical Stainless Steel (316L) are highly biocompatible. They are excellent choices for sensitive skin. Always check the specific material used.