Discover a professional 3D printing powder supplier

Bridging the Gap: How 3D Printing Supercharges Traditional Metal Casting

(how does 3d print to metal casting work)

Metal casting is an ancient art. People poured molten metal into molds for centuries. Creating those molds was often slow and expensive. This is where 3D printing steps in. It changes the game dramatically. This blend of old and new technology is fascinating. It offers huge benefits for making complex metal parts. Let us explore how 3D printing transforms metal casting.

1. What is 3D Printing for Metal Casting?

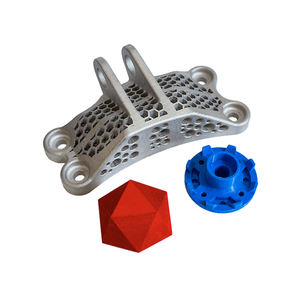

Think of metal casting like baking cookies. You need a mold to shape the dough. In metal casting, the mold shapes the molten metal. Traditionally, making this mold pattern involved carving wood or shaping clay. It took a long time. 3D printing for metal casting uses a different approach. It prints the pattern directly. The pattern is the shape you want your metal part to be. Instead of wood or clay, we use plastic or wax-like materials. A 3D printer builds this pattern layer by layer. It follows a digital design file. This printed pattern becomes the core of the casting process. It is placed inside a special sand box. The sand is packed around it. When the pattern is removed, it leaves a cavity. This cavity is the perfect shape for pouring molten metal. So, 3D printing creates the master copy for the mold quickly and precisely.

2. Why Use 3D Printing for Metal Casting Patterns?

Speed is a major reason. Carving a complex pattern by hand takes days or weeks. 3D printing can create the same pattern in hours. This drastically cuts down the time to get a finished metal part. Cost is another big factor. Making intricate patterns manually requires skilled labor. It is expensive. 3D printers automate this process. They reduce labor costs significantly. Design freedom is perhaps the biggest advantage. Traditional methods struggle with complex shapes. Think of internal channels or intricate details. 3D printing excels here. It can create patterns with almost any geometry. It is only limited by the designer’s imagination. This allows for parts that were impossible or too costly before. Prototyping becomes much faster too. Designers can print a pattern, cast a part, test it, and tweak the design quickly. This iterative process accelerates innovation. Using 3D printing reduces waste. It uses only the material needed for the pattern itself.

3. How Does 3D Printing Work in the Metal Casting Process?

The process starts with a digital design. Engineers create a 3D model on a computer. This model represents the final metal part. This file is sent to the 3D printer. The printer uses materials like special plastics or waxes. These materials are designed to burn away cleanly later. The printer builds the pattern layer by layer. It is a precise replica of the part design. Once printed, the pattern is ready for casting. Foundry workers use it to create a mold. The most common method is sand casting. The printed pattern is placed in a box. Special sand mixed with a binding agent is packed around it. The sand hardens. The pattern is then removed. Its removal leaves a cavity in the sand. This cavity matches the pattern’s shape exactly. Molten metal is poured into this cavity. The metal fills the space. It cools and solidifies. The sand mold is broken away. The rough metal casting is revealed. Any leftover sand is cleaned off. The casting might need finishing touches like grinding or machining. The printed pattern is often destroyed during mold making. But making a new one is easy and fast with the 3D printer.

4. Applications: Where is 3D Printed Metal Casting Used?

This technology is finding its way into many industries. Aerospace uses it heavily. Aircraft need strong, lightweight parts with complex shapes. Turbine blades and engine components are good examples. 3D printed patterns make creating these parts more efficient. The automotive industry benefits too. Car makers use it for prototypes and custom parts. Think of unique intake manifolds or specialized brackets. It helps them test new designs quickly. Art and sculpture have embraced this method. Artists can create intricate bronze sculptures. They first print the pattern digitally. This allows for amazing detail impossible by hand. Jewelry makers use it for detailed master patterns. They cast precious metals like gold and silver. Industrial machinery relies on it for bespoke parts. Pumps, valves, and gears often need custom shapes. Medical device manufacturing uses it too. Specialized surgical tools or implant prototypes are made this way. It offers speed and precision for low-volume production. Even heritage restoration uses this technique. Replicating damaged or missing parts for old machinery or structures becomes easier. The flexibility is key across all these fields.

5. FAQs: Common Questions About 3D Printing for Metal Casting

(how does 3d print to metal casting work)

Can any metal be cast this way? Yes, almost any metal that can be traditionally cast works. This includes aluminum, steel, iron, bronze, brass, and more. The printed pattern creates the mold cavity. The molten metal poured into it determines the final material. Are the final metal parts as strong as traditionally cast parts? Absolutely. The strength depends entirely on the metal alloy used and the casting quality. The mold creation method does not affect the metal’s inherent properties. A well-made sand mold produces a strong casting, regardless of how the pattern was made. How detailed can the cast parts be? Extremely detailed. 3D printers can capture fine features very well. The detail level depends on the printer’s resolution and the casting process control. It often surpasses traditional pattern-making methods. Is this process expensive? The initial setup for 3D printing has a cost. However, for complex parts or small batches, it is usually cheaper overall. It saves time and labor compared to traditional pattern making. The cost per part decreases significantly for prototypes or low volumes. What materials are used for the printed patterns? Common materials are photopolymer resins or special casting waxes. These materials are chosen because they burn out cleanly. They leave no ash residue when the mold is heated before casting. This ensures a smooth mold cavity surface. Can the same pattern be reused? Typically, the pattern is destroyed during the mold-making process. This is especially true for sand casting where the pattern is removed from the packed sand. However, since the pattern is digital, printing another identical one is simple and fast.