Discover a professional 3D printing powder supplier

Title: Metal from Machines: How 3D Printing Builds Real Steel

(how does 3d printing metal)

Product Keywords: 3D printing metal

1. What Exactly is Metal 3D Printing?

Forget plastic trinkets. Metal 3D printing is serious business. It builds real, solid metal parts directly from digital designs. Think of it like a super-precise robotic welder or a high-tech metal baker. Instead of cutting away material from a block, it adds material layer by tiny layer. The result? Complex shapes impossible with old methods, using tough metals like titanium, stainless steel, aluminum, or even exotic alloys. This technology has many names: additive manufacturing (AM), direct metal laser sintering (DMLS), selective laser melting (SLM), binder jetting. They all aim for the same goal: creating metal parts directly from a computer file. This process opens doors to designs once thought unmakeable.

2. Why Bother Printing Metal? What’s the Big Deal?

Traditional metalworking often means waste. Machining cuts away huge chunks of expensive metal. Casting needs complex molds that take ages to make. Metal 3D printing flips this. It uses only the metal needed for the part itself. This saves material and cuts costs for expensive alloys. The real magic is design freedom. Imagine parts with internal channels for cooling or fuel flow, hidden inside the solid metal. Think of lightweight structures like bone, strong but full of intricate holes. Printing makes these complex geometries easy. Need a unique part fast? Printing can do it quicker than setting up traditional tooling. It allows for custom medical implants matching a patient’s bone, or lightweight rocket parts impossible to machine. This flexibility changes how we design and make things.

3. How Does It Actually Work? Turning Powder into Parts

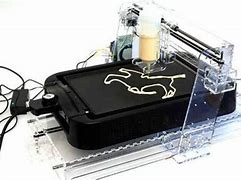

The details vary, but core ideas are similar. Most methods start with fine metal powder, finer than sand. Here’s a common process:

A thin layer of this powder spreads across a build platform inside a special machine chamber.

A powerful laser or electron beam precisely scans the powder layer. It follows the shape of the part’s cross-section from the digital file.

Where the beam hits, the metal powder melts and fuses solid. The surrounding powder stays loose, supporting the structure.

The build platform lowers slightly. Another layer of powder spreads on top.

The laser scans again, melting the new layer and fusing it to the one below.

This repeats hundreds or thousands of times. Layer by layer, the solid metal part grows upwards inside the powder bed.

Once finished, the entire block cools. Workers carefully remove the loose, unused powder (which can often be reused). The printed part might need some final machining or heat treatment. Other methods might use metal wire melted by an electric arc, or bind metal powder with a liquid glue before sintering it solid in a furnace. The laser-powder-bed method is very common for high-precision parts.

4. Where is Printed Metal Making Waves? Real-World Applications

This isn’t science fiction. Metal printing solves real problems right now:

Aerospace & Rockets: Weight is critical. Printing creates ultra-light, super-strong components like fuel nozzles, turbine blades, and structural brackets. Complex internal cooling channels in rocket engines are printed specialties.

Medical Implants: Titanium hip joints, spinal cages, and cranial plates can be printed to perfectly match a patient’s unique anatomy. The porous surface even helps bone grow into the implant.

Custom Tooling: Factories print specialized jigs, fixtures, and molds faster and cheaper than machining them. Conformal cooling channels inside molds improve plastic part quality.

Automotive: High-performance cars use printed parts for lighter weight and better performance. Prototyping new engine components is much faster.

Energy: Complex parts for gas turbines, heat exchangers, and oil & gas equipment benefit from printed designs that boost efficiency and durability.

Art & Jewelry: Designers create intricate, impossible metal sculptures and unique jewelry pieces.

5. FAQs: Your Metal Printing Questions Answered

Let’s tackle common questions:

Is it strong? Absolutely. Properly printed and processed metal parts meet or exceed the strength of traditionally made parts. They are dense, solid metal.

What metals can be printed? Many: Titanium alloys (Ti6Al4V), stainless steels (316L, 17-4PH), aluminum alloys (AlSi10Mg), tool steels, nickel superalloys (Inconel), cobalt-chrome, even precious metals like gold. New options develop constantly.

How smooth is the surface? As-printed parts often have a slightly rough, grainy surface. Post-processing like machining, polishing, or shot peening smooths them out for final use.

Is it expensive? Costs are high compared to mass production casting or stamping. It excels for complex parts, low volumes, custom items, or where weight savings justify the cost. Prices continue to fall as technology improves.

How big can parts be? Machines are getting bigger. Industrial printers can handle parts meters long, though most common machines build parts fitting within a shoebox to a microwave oven size. Larger parts can sometimes be printed in sections and joined.

(how does 3d printing metal)

Can I print at home? Not really. Industrial metal printers cost hundreds of thousands to millions of dollars. They need special facilities for handling fine metal powder (which can be hazardous) and powerful lasers. Safety is a major concern.