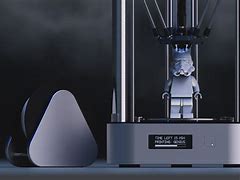

Discover a professional 3D printing powder supplier

Metal Magic: How 3D Printers Build Solid Objects Layer by Layer

(how does a 3d printer print metal)

Ever watched a machine seemingly conjure solid metal parts out of thin air? It sounds like science fiction, right? But it’s very real, and it’s called metal 3D printing. Forget the plastic trinkets you might be familiar with. This is about creating robust, complex metal components directly from digital designs. Let’s dive into this fascinating world.

1. What is Metal 3D Printing?

Metal 3D printing isn’t your average desktop printer spitting out paper. It’s a sophisticated manufacturing process. Think of it as building objects layer by layer, but using metal powder instead of ink or plastic. These machines don’t melt big blocks of metal. They build parts additively. This means they add tiny amounts of material precisely where needed. Several technologies exist. Some use lasers, others use electron beams or binders. The common goal? Creating strong, usable metal parts directly from a computer file. It opens doors to shapes traditional methods struggle with.

2. Why Print Metal? The Big Advantages

So, why bother printing metal when traditional methods like casting or machining exist? The reasons are compelling. First, it offers incredible design freedom. Engineers can create parts with intricate internal channels, honeycomb structures, or organic shapes that are impossible to machine. Second, it minimizes waste. Traditional methods often cut away significant material. Metal printing uses mostly what’s needed. Third, it allows for complex assemblies to be printed as a single piece. This reduces the need for multiple parts and assembly steps. Fourth, it enables rapid prototyping and production of custom or low-volume parts much faster than traditional tooling allows. Finally, it can work with challenging materials like titanium alloys used in aerospace.

3. How Does a 3D Printer Actually Print Metal?

The magic happens inside a sealed chamber. Let’s look at a common method called Powder Bed Fusion. Imagine a thin layer of fine metal powder spread evenly across a build platform. A powerful laser or electron beam scans across this powder bed. It follows the exact cross-section of the part defined by the digital model. Where the beam hits, the metal powder melts and fuses together. Once one layer is done, the build platform lowers slightly. A new layer of powder is spread on top. The beam then fuses this new layer, bonding it to the one below. This process repeats, layer by layer, until the entire part is built, buried within unused powder. After printing, the part cools inside the chamber. Then, technicians remove it from the powder cake. They break away the loose powder. Finally, the part often undergoes heat treatment to relieve stress and improve its strength. Support structures, printed alongside the part to prevent warping, are also removed during post-processing.

4. Cool Applications: Where Metal Printing Shines

This technology isn’t just a lab curiosity. It’s making real impacts across industries. Aerospace companies love it. They print lightweight, complex fuel nozzles and turbine blades for jet engines. These parts can withstand extreme heat and stress. The medical field benefits hugely. Surgeons use custom-printed titanium implants shaped perfectly to fit a patient’s bone structure. Dentists create precise crowns and bridges faster. Automotive manufacturers use it for high-performance parts. Think customized engine components or lightweight brackets. Even the energy sector uses printed metal parts. They go into turbines and drilling equipment. Artists and designers are exploring it too. They create unique sculptures and jewelry impossible to make otherwise. It enables rapid innovation and customization.

5. Metal 3D Printing FAQs: Your Questions Answered

People often have questions about this technology. Here are some common ones:

Are printed metal parts strong enough? Yes. Properly printed and processed parts can match or even exceed the strength of traditionally made parts. They are dense and fully metal.

Is it expensive? The machines and materials can be costly. But for complex, custom, or low-volume parts, it can be more economical than traditional methods needing expensive tooling. The waste reduction also helps.

How smooth is the surface? As-printed parts often have a slightly rough surface. They might need finishing like sandblasting or machining for a smooth look and feel. This depends on the printing method and settings.

What metals can be printed? Lots! Common ones include stainless steel, titanium alloys, aluminum alloys, nickel-based superalloys, cobalt-chrome, and even precious metals like gold. New materials are constantly being developed.

(how does a 3d printer print metal)

Is it fast? Printing a part takes time, hours or even days depending on size and complexity. But remember, it often eliminates weeks or months of tooling production needed for casting or molding. For prototyping and certain production, it’s significantly faster overall.