Discover a professional 3D printing powder supplier

Speed Demons: When 3D Printed Steel Components Outrun Tradition .

(how fast is a 3d printed metal part)

We reside in a world obsessed with speed. Faster net. Faster cars and trucks. Faster distribution. So normally, when steel parts jump from the digital globe right into your hand using 3D printing, one large question appears: exactly how fast is a 3D published steel component? It’s not nearly the printer humming along. It’s about the whole trip, from hitting “print” to holding a useful component. Let’s peel back the layers.

Keywords: 3D published steel components.

What Does “Fast” Mean for 3D Printed Metal? .

” Quick” seems easy. However, for 3D published steel components, it’s complicated. Think of constructing a sandcastle. You can dispose a big bucket of sand swiftly. That’s quick. Or you can painstakingly sculpt small details with a tiny tool. That’s slow yet accurate. Steel 3D printing deals with the same trade-off.

Rate right here isn’t just the device’s motion. It’s the complete time. This consists of preparing the digital data, warming up the printer, the actual printing, cooling off, removing the component, and cleansing it up (post-processing). The real printing time might seem long contrasted to machining a block of metal. However the actual magic? It commonly creates the whole part in one go . No awaiting several makers or devices. For complex forms, that’s a huge convenience overall. Rate is loved one.

Why 3D Printing Metal Can Be Much Faster Than You Believe .

Traditional metal component making commonly involves several steps. Casting demands molds. Machining needs reducing devices and setups. These actions require time, sometimes weeks. 3D printing metal sidesteps many of these obstacles.

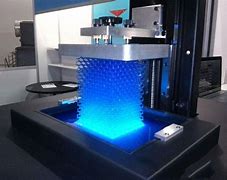

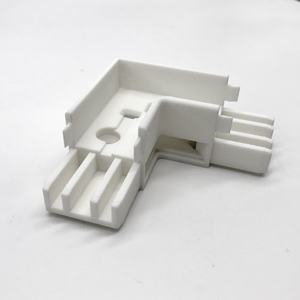

Think of requiring an unique bracket for a race car. Traditionally, you create it, make a mold and mildew, pour liquified metal, let it amazing, maker it to last size. Each step adds days. With steel 3D printing? You create the bracket on a computer system. Send the documents to the printer. The machine constructs it layer by layer straight from metal powder, merging it with a laser or electron light beam. The component comes out virtually complete, requiring only some completing. For one-off components or little batches, especially intricate ones, this process can be dramatically much faster. It eliminates the tooling delay. It consolidates producing steps. The clock begins ticking later, but finishes earlier for lots of work.

Exactly How Rate is Controlled in Metal 3D Printing .

You can’t just hit “turbo” on a steel 3D printer. Yet you can tweak settings to influence speed. Think about it like driving. The printer has setups that imitate the gas pedal and the steering wheel.

Layer density matters a great deal. Printing with thicker layers resembles taking bigger actions– you make strides quicker, however the surface area might be rougher. Thinner layers are smaller sized, much more specific actions, taking longer however offering a smoother surface. The laser (or electron beam of light) power and rate are important also. A much more powerful beam of light moving faster can thaw more powder quicker. However also quick or also effective? You take the chance of poor fusion or bending. The part’s size and complexity are obvious elements. A small, basic gear prints faster than a huge, intricate turbine blade. How densely the components are packed inside the printer’s develop chamber additionally impacts total print time. Load it full? You print more components at the same time, saving time per component. Pack it light? You may complete a solitary component earlier but utilize the equipment much less successfully. Locating the best balance is vital.

Applications Where Speed Makes All the Difference .

Rate in metal 3D printing isn’t simply convenient. It unlocks possibilities. Where does this speed advantage absolutely beam?

Prototyping is a huge one. Designers need examination parts quickly. Waiting weeks for conventional machining eliminates momentum. Metal 3D printing provides practical metal models in days, speeding up design cycles substantially. Extra parts for older equipment or unusual tools are one more winner. Rather than keeping pricey stock or waiting months for a new spreading, firms can publish the part on demand, reducing machine downtime. Custom medical implants, like titanium spine cages or hip mugs, benefit profoundly. Patient-specific geometry is very easy for 3D printing. Obtaining these distinct components made rapidly enhances individual treatment. Aerospace frequently pushes for lighter, more powerful get rid of intricate internal air conditioning networks. Publishing these elaborate parts directly is often quicker than setting up dozens of smaller pieces. Even in high-performance auto racing, the capability to layout, print, examination, and refine a new engine component within days gives groups a crucial side. Speed allows technology.

FAQs on 3D Printed Metal Component Speed .

Individuals constantly have inquiries about just how quick this really is. Here are some usual ones:.

Is it faster than CNC machining for every single component? No. For easy forms, especially high-volume manufacturing, CNC machining is normally much quicker per component. 3D printing shines with complexity, customization, and low-to-medium volumes where arrangement time for traditional techniques controls.

Can I get a metal part published overnight? Perhaps. It depends completely on the part’s size and intricacy. Little, basic components can sometimes be published in hours. Larger, complex parts can take days. Post-processing (eliminating supports, warmth treatment, surface ending up) adds more time.

Does faster printing mean lower high quality? Often, yes. Promoting maximum print rate generally includes concessions. This might suggest thicker layers (rougher surface area), much less enhanced laser settings (capacity for interior issues), or less assistance framework (threat of warping). Quality and rate need cautious harmonizing.

Just how much does speed up affect price? Printer time is expensive. Faster printing minimizes equipment time price per component. Yet hurrying can cause stopped working prints or poor quality, enhancing expenses. Optimizing settings for both rate and integrity is vital for cost-effectiveness.

(how fast is a 3d printed metal part)

Will metal 3D printing get significantly faster quickly? Yes, progression is constant. New modern technologies like several lasers working concurrently, faster scanning systems, and boosted powder handling are already improving rates. New steel alloys designed particularly for faster handling are likewise emerging. Expect constant enhancement.