Discover a professional 3D printing powder supplier

just how warm to 3d print steel

(how hot to 3d print metal)

What Is How Hot to 3D Print Steel .

When people ask how hot to 3d print metal, they are truly inquiring about the extreme temperature levels required to melt or fuse metal powders throughout additive production. Unlike printing with plastic, which could only require a few hundred levels Celsius, steel 3D printing needs much higher warm. The precise temperature depends on the kind of steel used. For instance, light weight aluminum melts around 660 ° C, while titanium requires concerning 1,668 ° C. Stainless-steel rests someplace in between at approximately 1,400– 1,450 ° C. These numbers are not simply trivia– they are vital to the success of the entire procedure. Without striking the best thermal sweet place, you end up with weak parts, warped shapes, and even fell short builds. If you would like to know more regarding which steels can actually be published, take a look at this overview on what kind of 3D printing can print metal.

Why Temperature Level Issues in Metal 3D Printing .

Obtaining the temperature incorrect in metal 3D printing leads to significant troubles. Also reduced, and the steel powder will not totally thaw or bond. That implies your final part might have fractures, openings, or bad mechanical toughness. Too high, and you run the risk of buckling the piece as a result of irregular cooling or perhaps harming the printer itself. Heat also impacts how the metal strengthens. A controlled cooling rate aids develop the appropriate microstructure inside the product, which straight influences durability and performance. In aerospace or clinical applications, where safety is non-negotiable, this control is whatever. That’s why designers invest so much time adjust laser power, check speed, and chamber temperature. It’s not nearly melting metal– it has to do with doing it exactly, consistently, and safely. Interested regarding whether you can really print a solid steel object in the house? See the reality in can you 3d print a piece of steel.

How Metal 3D Printing Gets To Extreme Temperatures .

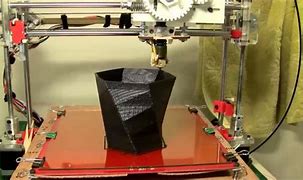

The majority of metal 3D printers make use of either main techniques: powder bed fusion or directed power deposition. In powder bed blend, a thin layer of steel powder is spread out throughout a build plate. Then, a high-powered laser or electron beam of light checks the surface area, melting specific spots to form a strong layer. This repeats until the complete item is constructed. The laser can get to temperature levels well above 2,000 ° C– sufficient to thaw also the hardest alloys. Electron beam of light systems work in a vacuum and use magnetic fields to guide the beam of light, often running hotter than lasers. Both systems require inert gas atmospheres (like argon) to stop oxidation. The entire device must be crafted to manage intense heat without warping. Even the construct chamber wall surfaces are particularly protected. So when somebody asks exactly how hot to 3d print steel, the solution isn’t simply a number– it’s a whole system created to handle that heat from beginning to end.

Applications That Count On Specific Steel Printing Temperatures .

Industries that depend on high-performance parts are the greatest customers of steel 3D printing. Aerospace business publish turbine blades and fuel nozzles that need to endure extreme heat and anxiety. Medical device manufacturers produce personalized implants– like hip joints– from biocompatible steels such as titanium, which have to be processed at specific temperature levels to make sure body compatibility and stamina. Automotive firms utilize it for light-weight, intricate engine components that improve performance. Even tooling and mold-making advantage, as conformal cooling networks can be published straight right into molds, something impossible with typical machining. All these applications share one point: they need regular, reliable outcomes. And that starts with toenailing the right temperature level every single time. If you’re wondering about the real-world price of all this precision, take a look at how much does 3D printing in steel cost.

FAQs Regarding Exactly How Warm to 3D Print Metal .

Can you 3D print steel at home? No, not actually. The machines are pricey, require special precaution, and run at precariously heats. Many home configurations can’t take care of steel powders or the energy needed to melt them.

Does every metal require the same temperature level? No. Each alloy has its own melting factor and ideal processing window. Inconel, for instance, requires much more warmth than aluminum.

Why can not I simply utilize a regular 3D printer with metal filament? Some “metal-filled” filaments exist, but they’re mainly plastic with steel dirt. After printing, they need to be sintered in a kiln– a separate, high-heat step. True metal 3D printing avoids the plastic completely.

Is greater temperature level always better? Not. Excess warm causes grain growth, recurring stress, and distortion. Accuracy issues greater than raw power.

Just how do printers control such high warm? Via innovative software program, calibrated lasers or electron beam of lights, and sealed chambers full of inert gas. Sensors constantly keep track of problems to readjust in genuine time.

(how hot to 3d print metal)

Understanding how warm to 3d print metal isn’t almost cranking up the heat. It’s about understanding a fragile equilibrium between product scientific research, design, and thermal control. Obtain it right, and you open opportunities that typical manufacturing merely can’t match.