Discover a professional 3D printing powder supplier

From Alchemy to Automation: The Shocking History of Metal 3D Printing .

(how long have metals been 3d printed)

Metal 3D printing seems like natural science fiction. Visualize creating complicated metal parts directly from a computer file. No giant mold and mildews. No mountains of metal shavings. Just pure, accurate steel magic. But the length of time have we really been doing this? The response is longer than you might think. Let’s study the fascinating journey of transforming steel powder into effective fact.

Main Item Search Phrase: Metal 3D Printing.

1. What is Steel 3D Printing? .

Metal 3D printing is a means to build strong steel items layer by layer. It makes use of a digital design data as the blueprint. Think about it like a really precise, very warm inkjet printer. However as opposed to ink, it utilizes steel powder or cable. As opposed to paper, it builds on a system inside a special machine. The core concept is additive manufacturing. This means including material only where needed. This is different from old techniques like reducing or sculpting metal away. It creates much less waste. It permits forms difficult to make before. Think detailed air conditioning channels inside an engine component. Assume light-weight, strong structures imitating bone. This is the power of metal 3D printing. It transforms electronic dreams into concrete metal.

2. Why Usage Steel 3D Printing? .

Why select steel 3D printing over standard approaches? The factors are strong. First, it allows extraordinary design flexibility. Complex forms, interior features, latticeworks– these are easy for 3D printing. They are often difficult or too pricey with spreading or machining. Second, it makes lightweight parts. Solid parts make use of less product. This is essential for markets like aerospace and auto racing. Lighter airplanes and cars and trucks use much less fuel. Third, it minimizes waste dramatically. Traditional machining can junk over 90% of a steel block. Steel 3D printing makes use of mainly just the material required for the last component. Fourth, it quickens making prototypes. Testing brand-new styles happens much faster. Fifth, it makes it possible for mass modification. Making unique components, like custom-made clinical implants, comes to be sensible. Sixth, it simplifies assemblies. Printing multiple parts as one strong piece minimizes failures. It makes points stronger.

3. Exactly How Does Metal 3D Printing In Fact Function? .

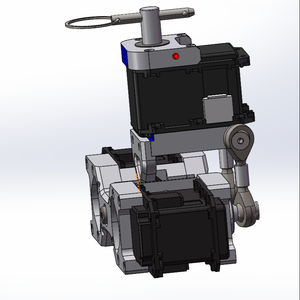

So just how do these machines turn powder right into strong steel? Numerous methods exist. The most typical are Powder Bed Fusion approaches. DMLS (Direct Metal Laser Sintering) and SLM (Selective Laser Melting) are preferred kinds. Here’s the basic idea. A thin layer of great metal powder tops a construct system. Then a powerful laser beam scans the powder. The laser follows the shape of one cross-section of the part. The laser thaws or sinters the steel particles with each other. Sintering fuses them without complete melting. Then the system reduces somewhat. An additional layer of powder spreads on the top. The laser after that thaws or sinters this brand-new layer. It additionally bonds it to the layer listed below. This repeats. Layer by layer, the part builds up inside a chamber filled with inert gas. This gas prevents the warm metal from reacting with oxygen. After printing, the component cools inside the powder. Workers after that dig it out. They remove additional powder. Sustains added throughout printing obtain removed. Lastly, the component often needs warmth therapy. This improves its toughness. Various other techniques exist as well. Binder Jetting sprays a glue-like binder onto powder layers. Metal Extrusion presses metal-paste through a nozzle. Directed Power Deposition (DED) blows steel powder right into a melt swimming pool produced by a laser or electron beam. Each approach fits different demands.

4. Where is Steel 3D Printing Used? Applications Galore .

Metal 3D printing isn’t just a lab plaything anymore. It’s making real points in crucial areas. Aerospace loves it. Business publish jet engine components, gas nozzles, and lightweight braces. These components execute much better. They consider less. This conserves fuel. The clinical field uses it greatly. Surgeons dental implant custom-made 3D published titanium hip joints, knee substitutes, and back cages. These fit people flawlessly. Oral laboratories publish crowns and bridges quickly. The automotive industry uses it. Race vehicles get maximized, printed components. Normal cars get prototypes and custom-made tools quicker. Toolmakers profit. They print mold and mildews with complex air conditioning networks. These molds make plastic components faster and better. The power field utilizes it. Companies publish components for oil and gas removal. They print elements for power generation. Also the precious jewelry industry makes use of precious metal printing. Musicians develop difficult designs. Primarily, anywhere solid, intricate, or custom steel parts are needed, metal 3D printing is locating its place. It fixes hard design issues.

5. Steel 3D Printing Frequently Asked Questions: Your Burning Concerns Responded To .

Lots of people have concerns about this technology. Right here are some usual ones:.

Exactly how strong are 3D published steel parts? Properly printed and processed parts are extremely solid. They can be as solid, in some cases more powerful, than components made the old way. The secret is making use of the appropriate settings. Post-processing like heat treatment is vital.

Is it actually cost-efficient? It depends. For straightforward forms made in lots, conventional approaches are usually cheaper. For intricate components, customized one-offs, or light-weight styles, metal 3D printing normally saves cash. It conserves material. It avoids expensive tooling. It accelerates development.

What steels can be published? Lots! Titanium alloys are preferred for implants and aerospace. Stainless steels prevail for tools and industrial parts. Light weight aluminum alloys are fantastic for light-weight requirements. Nickel superalloys deal with extreme warmth in engines. Cobalt-chrome works well for dental and clinical. Copper, gold, silver, and even tungsten are too. The checklist keeps growing.

For how long does it take to publish a component? Printing time varies a lot. A little, easy part might take a couple of hours. A big, complicated part might take days. Bear in mind, post-processing adds more time. Yet contrasted to making a mold for spreading, it can be much quicker general.

Exist size limitations? Yes, the build chamber size restricts the part size. Industrial printers can make components over a meter tall. But genuinely massive parts require traditional techniques. Or, huge components can be printed in areas and bonded.

(how long have metals been 3d printed)

Is the surface area coating good? Right off the printer, the surface area is often rough. It has a rough appearance. The majority of parts need machining, brightening, or other finishing to get smooth. Think of the print as producing the “close to web form”. Completing makes it perfect.