Discover a professional 3D printing powder supplier

** Crafting Laser Paths for Flawless Steel 3D Prints **.

(how make scan path metal 3d printing)

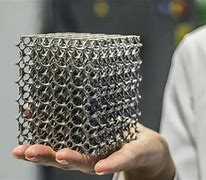

Steel 3D printing seems like magic. You make a component on a computer, hit print, and enjoy layers of steel fuse into truth. But behind the scenes, there’s a covert hero: the check course. This is the path the laser or electron beam takes to thaw metal powder into strong shapes. Getting it right implies the difference between a strong work of art and a fractured mess. Allow’s break down just how to plan these paths like a pro.

Initially, comprehend what a check course does. Picture cutting a yard. If you zigzag randomly, you’ll leave patches of high turf. Do it in cool rows, and the outcome is smooth. The exact same logic applies to 3D printing. The laser must move in patterns that uniformly disperse heat, prevent overlaps, and protect against bending. Mess this up, and anxiety builds up inside the metal, resulting in cracks or distortions.

So exactly how do you create an excellent check course? Start with the fundamentals. The majority of printers make use of an approach called “hatching,” where the laser fills areas with identical lines. Yet spacing matters. As well close, and warmth accumulate. Too much, and layers won’t bond. Software application devices assist here, allowing you fine-tune specifications like hatch range and check speed. Still, no software application can replace human instinct. You need to balance rate with accuracy.

Warm monitoring is one more huge offer. Steel cools rapidly, however unequal air conditioning causes difficulty. One trick is revolving the scan instructions in between layers. If layer one has straight lines, layer two shifts to diagonal, and layer 3 goes upright. This spreads out warmth much more uniformly, like turning a pan in the stove to bake cookies perfectly. Some experts even utilize spiral or fractal patterns to stay clear of hot spots.

Geometry additionally contributes. Facility forms require adaptable techniques. Sharp edges? Reduce the laser there to prevent getting too hot. Thin wall surfaces? Usage much shorter scan lines to keep the framework stable. Think about it like drawing with a pen– press more challenging on thick lines, lighter on fragile information.

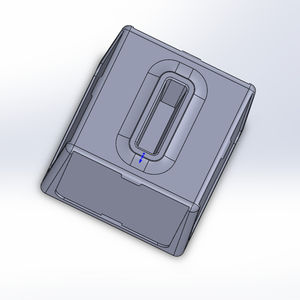

Software does the hefty lifting, however you still need to guide it. Programs like Netfabb or Materialise Magics allow you imitate just how heat moves throughout printing. Run examinations, area weak points, and readjust the path. Some systems even use AI to predict tension factors and auto-correct the check course. Still, always double-check. Equipments learn from mistakes, but humans fix them much faster.

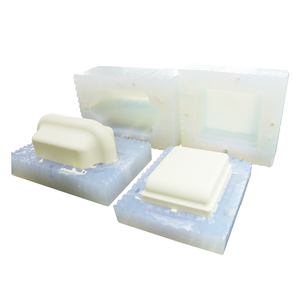

Obstacles pop up all over. Recurring stress and anxiety is a sneaky one. Despite having best scan courses, metal can warp as it cools down. Preheating the construct plate helps, but so does including assistance frameworks. These imitate scaffolding, holding the component in place until it’s completely cooled down. Simply keep in mind to eliminate them later– nobody desires additional steel balls spoiling their layout.

New tech is changing the video game. Multi-laser systems can divide the job, reducing print time while keeping warm balanced. Real-time monitoring devices utilize cameras and sensing units to track melt swimming pools, adjusting the scan course instantly if something looks off. Scientists are even checking adaptive paths that change mid-print based on thermal data.

(how make scan path metal 3d printing)

The future looks brilliant. As equipments obtain smarter, scan path planning will blend human creativity with AI accuracy. However, for now, mastering the basics– warm control, geometry tweaks, and clever software use– is vital. Every excellent metal print starts with a well-crafted laser dancing.