Discover a professional 3D printing powder supplier

**What’s the Price Tag on 3D Printing a Metal Piece? Spoiler: It’s Not Just About the Money**

(how much does it cost to get a metal part 3d printed)

So you want to 3D print a metal part. Maybe it’s a custom gear for your bike, a prototype for an invention, or a replacement piece for a broken appliance. Whatever it is, the first question that pops up is: *How much will this cost?* The answer isn’t as simple as a number on a receipt. Let’s dig into what shapes the price—and why “cheap” might not always be the best goal.

First, the type of metal matters. Aluminum is common and affordable. Stainless steel costs a bit more. Titanium or nickel alloys? Those can make your wallet wince. The material choice affects durability, weight, and how the part behaves under stress. Picking the right metal isn’t just about cost—it’s about function.

Next, size plays a role. A tiny bracket might use $10 worth of material. A larger component could need $200 or more. But wait—bigger parts also take longer to print. Machines run for hours, sometimes days. Time equals electricity, labor, and machine wear. A palm-sized piece might cost $50. A football-sized one? Maybe $500.

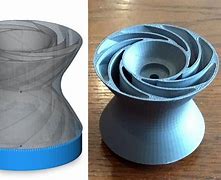

Design complexity is another factor. A basic shape with smooth surfaces is easier to print. Intricate details, hollow sections, or fine threads need more precision. Complex designs eat up time and require supports—temporary structures that hold the part steady during printing. More supports mean more material, more post-processing, and higher costs.

Who you hire matters too. Online services offer convenience but might mark up prices. Local workshops could be cheaper but lack advanced equipment. High-end industrial firms charge premium rates but deliver flawless finishes. Always ask for quotes. Compare not just prices but quality guarantees.

Post-processing sneaks into the bill too. Freshly printed metal parts often look rough. They might need sanding, polishing, or heat treatment. Some require machining to meet exact specs. These steps add labor and time. A part that costs $100 to print could jump to $200 after finishing touches.

Location isn’t irrelevant. Shipping heavy metal parts isn’t free. If you’re sourcing from overseas, taxes or import fees might bite. Local production avoids this but might limit material options.

Now for the big question: What’s the average cost? For a small, simple aluminum part, budget around $50 to $150. Stainless steel could push it to $200. Fancy metals or complex designs? Think $300 to $1,000+. But here’s the kicker—the cheapest option isn’t always smart. A poorly printed part might break, misfit, or corrode fast. Paying a little extra for quality saves headaches later.

Want to save cash? Simplify your design. Remove unnecessary details. Stick to standard sizes to avoid custom fees. Order multiple parts at once—bulk discounts exist. Some companies even offer lower rates for slower turnaround times.

(how much does it cost to get a metal part 3d printed)

At the end of the day, 3D printing metal isn’t like buying a soda. Prices swing wildly because every project is unique. But understanding the variables helps you make smarter choices—and maybe even haggle like a pro.