Discover a professional 3D printing powder supplier

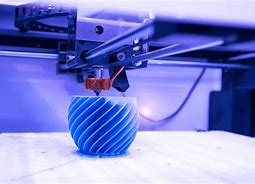

**Metal 3D Printing: What’s the Damage to Your Wallet?**

(how much does it cost to get a part metal 3d printed)

So you want to 3D print a metal part. Cool idea. But let’s cut to the chase: How much cash are we talking here? The answer isn’t as simple as slapping a price tag on it. Think of it like ordering pizza. The base cost gets you cheese and crust, but toppings? Those add up. Metal 3D printing works the same way. Let’s break it down.

First, material matters. Not all metals cost the same. Aluminum or stainless steel? Budget-friendly options. Titanium or nickel alloys? Prepare to pay more. Prices swing from $50 per kilogram for basic metals to $500+ for aerospace-grade stuff. The chunkier your part, the more material you burn. Simple math.

Next, machine time. Metal printers aren’t cheap to run. Industrial machines guzzle power and need expert handling. Hourly rates range from $100 to $300. A small bracket might take two hours. A complex engine component? Days. Time equals money here.

Also, design complexity. Fancy geometries with lattices or internal channels? Cool, but tricky. More design work means higher prep costs. Engineers might charge $200-$500 to tweak your file for printing. Messy designs waste material or cause print fails. Avoid that.

Another thing: post-processing. Freshly printed metal parts aren’t ready to roll. They need cleaning, heat treatment, or machining. Support structures? Those get chopped off. Smooth surfaces? Add grinding or polishing. Each step adds 10%-30% to the total.

Location and provider matter too. Local shops cut shipping costs but might charge more for labor. Overseas suppliers offer lower rates but risk delays. Big companies like Shapeways or Protolabs have set prices. Small shops might haggle. Shop around.

Quantity plays a role. Printing one tiny screw? Expect a premium. Bulk orders? Prices drop. Some shops offer discounts for repeat jobs. If you’re prototyping, start small. Scale up once the design’s nailed.

Still fuzzy on numbers? Let’s ballpark. A fist-sized aluminum part with simple geometry: $200-$500. Same size in titanium with intricate details? $1,000-$2,500. Bigger parts? Add zeros. Always ask for a detailed quote. Hidden fees love to crash the party.

Want to save cash? Simplify your design. Reduce hollow spaces or thin walls. Pick common metals. Batch multiple parts in one print. Skip unnecessary finishes. Compare quotes like a pro.

(how much does it cost to get a part metal 3d printed)

Metal 3D printing isn’t cheap, but it’s magic for custom, strong parts. Costs swing wildly, but now you know the levers to pull.