Discover a professional 3D printing powder supplier

Title: Metal Matters: The Bare Minimum for Practical 3D Printed Firearms .

(how much metal does a 3d printed gun have o contain)

Just what is the “Metal” Demand? .

Allow’s cut through the lingo. When individuals discuss “steel” in a 3D published gun, they aren’t typically talking about the whole thing being shiny steel. Most functional published guns make use of plastic polymers for the main body– the grasp, the framework, the housing. The vital “steel” component refers particularly to parts that should manage severe pressure and warmth during shooting. Think of the barrel (where the bullet takes off down) and typically the screw or shooting pin assembly. These parts experience pressures that plastic simply can’t hold up against dependably. The need isn’t about weight or looks. It’s purely about physics. Blowing up gunpowder develops tremendous pressure and heat. Plastic thaws. Plastic warps. Plastic shatters. Metal, particularly certain qualities of steel or titanium, withstands this. So, the “metal” mandated is the outright vital equipment required to consist of the bang safely, also just as soon as. Without it, the gadget is dangerously uncertain, extra like a pipeline bomb than a firearm.

Why Can Not You Just Publish the entire Point in Plastic? .

Safety and security. Dependability. Validity. Publishing a whole gun in plastic is practically feasible for some basic layouts. The outcomes are typically dreadful and unbelievably hazardous. Plastic barrels lump, crack, or burst under shooting stress. This isn’t just a misfire; it’s a disastrous failure inches from your hand and face. Shrapnel flies. The gun essentially takes off. This makes them unusable for anything past a single, risky examination shot. Lawfully, in position like the United States, the ATF (Bureau of Alcohol, Cigarette, Firearms and Dynamites) defines a weapon partly by its capability to fire projectiles. Crucially, they additionally have regulations about “undetected weapons.” A gun made entirely of plastic can possibly evade steel detectors. To avoid this, government legislation requireds that any useful weapon have to consist of enough metal to be observable by typical safety screening devices. This isn’t an idea. It’s a tough requirement to stop plastic guns from coming to be unseen protection risks. So, metal isn’t practically making the weapon job; it’s about making it obvious and marginally more secure.

Exactly how Do You Actually Integrate the Metal? .

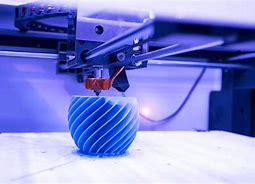

It’s less concerning publishing steel and even more concerning adding it. While metal 3D printing exists, it’s pricey, complicated, and usually not easily accessible for hobbyists making firearms. The common technique uses hybrid production. The main body– the framework, receiver, hold– is printed using strong thermoplastics like ABS, Nylon, or specialized PLA blends on a common desktop FDM printer. This develops the framework. The crucial steel elements are separate, pre-made things. These are usually straightforward, unregulated pieces of metal equipment. Think about things like:.

Barrel Liners: A short length of steel pipe or tubing inserted into the printed plastic barrel shadow. This steel tube is what actually has the surge and overviews the bullet.

Screw Elements: A solid steel screw face, shooting pin, or extractor claw. These parts pound forward and back, handling influence pressures plastic can’t.

Pins and Springs: Important steel pins for triggers and screws, plus springs.

The printed plastic parts are created with details ports, holes, or channels. You print the plastic covering. After that, you physically insert, adhesive, or screw these pre-made metal components right into their marked areas. The plastic acts as the housing and structural assistance. The embedded steel components take care of the important shooting tensions. Obtaining the dimensions right for these inserts is essential for the gun to function safely. A badly fitted barrel liner is just as hazardous as no metal at all.

Where Do These Hybrid Guns Program Up? .

The applications are niche and debatable. You won’t discover these in routine weapon shops or military collections. Their existence is largely in 2 areas:.

1. Home Hobbyists & Experimenters: Some tech-savvy firearms lovers see 3D printing as an expansion of typical gunsmithing. They appreciate the difficulty of designing, printing, and constructing useful tools themselves, typically concentrating on historical reproductions or novel concepts. For them, it has to do with the technical accomplishment and understanding mechanics, not necessarily producing practical tools. On the internet communities share documents and construct overviews, highlighting safety and security and validity (like including the called for steel).

2. Illicit Manufacturing & Ghost Guns: This is the darker side. Wrongdoers and people prohibited from purchasing weapons look for untraceable weapons. A 3D printer and some basic hardware shop metal parts provide a means to make a weapon without any identification number, no background check. These are frequently unrefined, single-use “zip weapons” developed for minimal metal material– simply sufficient to maybe work once and escape discovery briefly. Police worldwide are increasingly encountering these unserialized, home made plastic-and-metal crossbreeds during examinations. They stand for a substantial challenge for mapping and control.

Frequently Asked Questions: Breaking Misconceptions Concerning 3D Printed Gun Metal .

1. Is there a certain weight or portion of metal needed? No taken care of weight. The demand is functional and legal. Functionally, sufficient steel has to be present in important tension points (barrel, bolt) to securely have firing pressure. Legally (in the United States), enough metal should be present to set off standard airport-style metal detectors (usually comparable to around 3.7 ounces/105 grams of steel). Fulfilling the discovery need typically pleases the practical minimum for extremely simple designs.

2. Can you 3D print the metal components directly? Technically yes, but practically no for the majority of. Industrial metal 3D printers (like DMLS/SLM) can create high-strength parts, yet they cost 10s or thousands of countless dollars. Desktop steel printing (like FDM with metal filament) generates parts that are metal-filled plastic , hollow metal. They lack the density and stamina needed for weapon parts. They may assist meet the detectability weight, however they will fail catastrophically under shooting pressure. Actual firearm-grade metal parts need traditional machining or specialized industrial 3D printing.

3. Does the metal have to be a specific kind? Functionally, yes. It needs to be strong sufficient. Light steel may benefit a single shot in an unrefined style. Proper firearm barrels make use of details, solidified steel alloys (like 4140 or 4150 chromoly steel) to take care of duplicated firing and high pressures. The legal detectability demand does not define the alloy, simply the obvious mass equivalent.

4. Are plastic-only weapons actually that dangerous? Exceptionally. Attempting to terminate any type of significant quality (also.22 LR) via a plastic-only barrel is highly most likely to lead to a catastrophic failure. The plastic can not contain the stress. This risks severe injury or death to the individual from shrapnel and the explosion itself. They are not viable guns.

(how much metal does a 3d printed gun have o contain)

5. Is it lawful to make one? Legitimacy differs enormously by nation and even within countries/states. In many places, producing any kind of firearm without a license is illegal. Also where home manufacturing might be legal for personal usage (like some interpretations in the US), stringent regulations apply. These consist of the undetectable firearms act (needing noticeable steel), prohibitions on totally automatic tools, and bans for forbidden persons. Lack of knowledge is not a defense. The legal risks are substantial.