Discover a professional 3D printing powder supplier

Metal vs. Plastic 3D Printing: Is the Price Jump Worth It? .

(how much more does 3d printing metal cost vs resin or plastic)

So you’ve seen the amazing things 3D printers can do. Possibly you began with plastic or resin. After that you hear about publishing steel. It seems effective. But one question appears: Just how much a lot more does 3D printing steel really cost contrasted to material or plastic? The answer isn’t just one number. It’s a whole tale about products, devices, and what you in fact require. Allow’s damage down the actual cost of stepping into metal.

1. What Makes Steel 3D Printing A Lot Much More Pricey? .

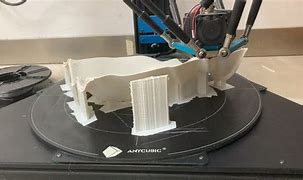

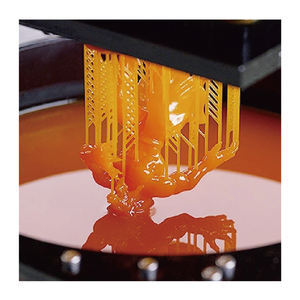

Metal 3D printing isn’t simply swapping plastic for steel powder. It’s a different world. First, the machines themselves. Industrial steel printers, like those using SLM (Selective Laser Melting) or DMLS (Direct Steel Laser Sintering), are complicated monsters. They need powerful lasers, firmly managed inert concentration camp (generally argon or nitrogen), and super-precise heater. This tech costs lots of money. Assume numerous thousands of dollars, conveniently reaching into the millions. Contrast that to a great desktop FDM (plastic) or SLA/DLP (material) printer costing a few hundred to a couple of thousand dollars.

Next, the raw stuff. Steel powders aren’t like plastic filament or fluid material. Making them is hard. Particles require to be flawlessly spherical and extremely penalty. For steels like titanium, Inconel, or stainless steel, the powder cost per kilogram is high. Often 10 times or more than leading design plastics. Resins sit somewhere in the middle price-wise.

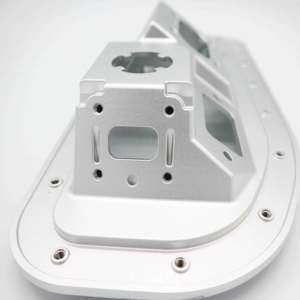

After that comes the after-party. Metal parts fresh off the printer are normally adhered to a construct plate and surrounded by extra powder. They need cautious removal. Extra significantly, they often require major warmth treatment in a furnace (tension eliminating or warm isostatic pressing – HIP). This makes them solid and sturdy. Finally, exact machining is almost always needed to accomplish smooth surface areas and specific dimensions. Plastic and resin parts need support removal and possibly some sanding or treating. Steel requires a commercial post-processing line. This adds significant time and cost.

2. Why Does Steel Expense More Than Material or Plastic? .

The cost gap come down to physics and precision. Thawing steel, even tiny particles, demands extreme power. Those lasers are power-hungry. Keeping oxygen out during printing is crucial. Oxygen damages steel components. This needs sealed chambers and constant gas circulation. Plastic and material printing occur mostly in outdoors or basic covers.

Safety and security is one more huge element. Fine metal powders can be explosive and are certainly bad to take a breath. Handling them calls for special equipment, like handwear cover boxes, and stringent treatments. Ventilation systems should be top-notch. Splashed plastic filament is irritating. Spilled steel powder is a hazard. This contributes to the operational price and complexity.

The equipments themselves are developed to last under extreme problems. Think high temperatures and constant laser shooting. This requires robust, expensive elements. Desktop computer plastic printers make use of easier technicians and electronics. Material printers rely upon specific source of lights but stay clear of the thermal extremes of metal. The intricacy drives the first financial investment overpriced.

Ultimately, the scale is different. Industrial steel printing targets high-value parts for demanding markets. Lower-volume production suggests costs aren’t spread out thin like mass-produced plastic things. Every part lugs even more of the device’s overhead.

3. How Do the Costs Really Compare? .

Allow’s get functional. Forget just the printer price. Believe “total price per part.” This includes the equipment (spread over its life), materials, labor, power, and post-processing.

Equipment Cost (Devaluation): Metal printers set you back greatly a lot more. Spreading this price over the components made makes each metal component begin costly. Plastic/resin devices are more affordable. Their expense per part is much lower.

Product Cost: Steel powders win the “most expensive material” prize. Common engineering plastics (like Nylon, ABS) set you back $20-$ 100/kg. Advanced resins may be $100-$ 300/kg. Typical metal powders? Titanium can be $300-$ 600/kg. Stainless steel $80-$ 150/kg. Aluminum $50-$ 100/kg. You utilize extra worldly also, as parts are usually solid or near-solid.

Power: Melting metal with lasers makes use of much more electricity than extruding plastic or healing resin.

Labor: Operating a steel printer often requires customized training. Post-processing metal components is labor-intensive and needs skilled machinists. Plastic/resin assistance elimination is easier.

Post-Processing: Heat treatment furnaces and precision CNC machining for steel components are significant price facilities. Plastic may require a little sanding. Resin requires cleaning and healing.

Outcome: A little, easy metal part could set you back numerous dollars. A similar plastic part could set you back a few dollars. Resin sits closer to plastic yet can be greater for big, thick components. Metal just becomes affordable for complicated, high-value components where its unique advantages (toughness, warm resistance, complicated interior structures) warrant the cost. Believe airplane braces or personalized medical implants. For prototypes or decorative items? Plastic or resin victories on cost each time.

4. Applications: Where Metal Printing’s Price Makes good sense .

Why pay the steel costs? Since occasionally only steel will certainly do. The cost is warranted when the part’s function needs metal buildings. Right here’s where it beams:.

Aerospace & Protection: Weight is vital. Strength is non-negotiable. Steel printing makes complex, light-weight titanium or Inconel parts impossible to device generally. Believe gas nozzles, generator blades, architectural brackets. The cost is high, however so is the worth of performance and weight cost savings.

Medical & Dental: Biocompatibility is key. Titanium is the gold requirement for bone implants. Custom-made, patient-specific implants (knees, spine cages) are excellent for metal printing. Dental crowns, bridges, and copings made from cobalt-chrome are strong and specific. The cost per component is acceptable for these essential applications.

Automotive (High-Performance): Competing teams use steel printing for custom, maximized components like turbocharger real estates, warm exchangers, or suspension elements. Reducing weight or enhancing warmth administration warrants the cost on top rate. Mainstream production? Still mostly plastic prototyping and tooling.

Industrial Tooling & End-Use Components: Producing complicated shot molds with conformal cooling channels drastically cuts cycle times. The high mold expense is offset by huge manufacturing gains. Publishing solid, sturdy jigs, components, or replacement components for heavy machinery conserves downtime. The cost defeats waiting weeks for a machined component.

Power (Oil & Gas, Power): Parts needing severe warmth, corrosion resistance, or pressure resistance in severe settings. Assume shutoff parts, warm exchanger components. Metal printing delivers alloys that can handle it.

In these locations, steel 3D printing isn’t just a choice; it’s the best option. The greater price buys unique efficiency, personalization, and rate for critical parts.

5. Metal 3D Printing Expense FAQs .

Allow’s take on some common money questions:.

Is metal printing always much more costly than machining? No. For straightforward forms machined easily from supply product, machining is usually less expensive. Metal printing wins when the part is very complicated (internal networks, lattices), needs pricey alloys with high waste in machining, or needs quick manufacturing of custom one-offs. It often matches machining.

Can I obtain low-cost metal printing solutions? “Inexpensive” is loved one. Solution bureaus make metal printing available without getting an equipment. Prices are still high compared to plastic/resin solutions. Anticipate $100s for little parts. Rates rely on material, dimension, intricacy, and post-processing demands. Get quotes!

Are material expenses dropping? Gradually. As even more metal powder providers get in the marketplace and production scales, rates inch down. But the basic procedures (atomization) stay costly. Do not expect plastic-like costs soon.

Does component dimension significantly transform the cost comparison? Yes. Bigger metal parts require larger, much more expensive equipments, more powder, longer print times, and extra intricate post-processing. The expense void widens substantially contrasted to big plastic parts. Plastic/resin ranges up extra economically.

Is the cost practically the print? Not! Bear in mind post-processing. Factor in stress and anxiety easing, HIP (if needed), support elimination, and machining. This can conveniently double the effective part expense. Plastic/resin parts avoid the furnace and heavy machining.

(how much more does 3d printing metal cost vs resin or plastic)

The steel 3D printing price tag is a fact check. It’s an effective tool, however not an inexpensive one. Understanding the “why” behind the expense aids choose when it’s the appropriate option. For stamina, heat resistance, and intricate geometry in vital applications, that expense purchases unparalleled value. For everything else? Plastic and resin maintain the spending plan pleased.