Discover a professional 3D printing powder supplier

** Can 3D-Printed Metal Components Actually Take the Warm? The Reality About Their Strength **.

(how strong are 3d metal printed parts)

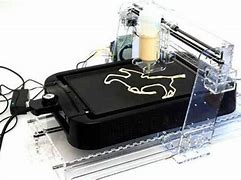

Envision building a car engine, a rocket nozzle, or perhaps a bone dental implant layer by layer– like stacking microscopic steel pancakes. This is what 3D metal printing does. However here’s the large concern: are these printed parts difficult enough to take care of real-world needs, or do they crumble under stress? Let’s go into the gritty details.

Initially, understand this: 3D steel printing isn’t your average workplace printer. It uses lasers or electron beam of lights to melt steel powder into solid forms. The products? Titanium, stainless-steel, aluminum– things you ‘d find in airplanes or clinical tools. The process seems futuristic, yet the actual magic remains in the stamina.

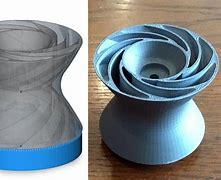

People usually believe printed steel parts are weak since they’re made in layers. Traditional methods like building or casting thaw, extra pound, or mold steel right into form, developing consistent frameworks. Printed parts, however, have tiny layers integrated with each other. Skeptics stress these layers might crack or split. Yet here’s the spin: modern-day 3D printers are so accurate, the bonds between layers are nearly smooth. Examinations reveal published parts can match– and occasionally defeat– the toughness of traditionally made ones.

Take aerospace, for instance. Companies like SpaceX and GE make use of 3D-printed metal components in rockets and jet engines. These components deal with extreme warmth, stress, and resonances. If they fell short, the results would certainly be catastrophic. However they do not. Why? The key remains in the style versatility. 3D printing lets engineers create forms difficult to make with traditional techniques. Honeycomb frameworks, inner air conditioning networks, or hollow rooms minimize weight without sacrificing stamina. Much less weight means better fuel effectiveness in aircrafts or faster speeds in automobiles.

One more element is worldly science. Scientist tweak steel powders to boost efficiency. Some mixes consist of ceramics or carbon fibers for extra durability. Post-processing actions like heat therapy or polishing additionally assist. Home heating printed components in a heating system ravels tiny flaws, making them denser and stronger.

But it’s not all plain sailing. Layer-by-layer printing can leave tiny gaps or irregular areas, especially if the printer isn’t calibrated perfectly. Moisture, temperature, or perhaps a fleck of dirt can ruin the procedure. Designers are still determining how to ensure every component appears flawless. In the meantime, strict top quality checks and advanced scanners assist identify weaknesses prior to components go into use.

Real-world instances confirm the possibility. Clinical implants made through 3D printing fuse with human bone better than mass-produced ones. Customized shapes fit individuals perfectly, lowering surgery time and boosting recovery. Vehicle companies print lightweight brake components that manage high stress without overheating. Even the military usages printed metal parts in vehicles and tools, where failure isn’t a choice.

Price is an additional angle. Printing complex steel components can be less costly than machining them from strong blocks. Much less material waste, faster production times, and no demand for costly molds make it enticing. As printers get faster and products less expensive, sectors from building to robotics are jumping on board.

Still, difficulties remain. Not all steels print similarly well. Some fracture under stress and anxiety or corrode much faster. Designers are racing to create new alloys and printing methods to fix these concerns. The goal? Make 3D-printed metal parts as trusted as conventional ones, but with the benefit of wild, ingenious layouts.

(how strong are 3d metal printed parts)

So, can 3D-printed metal parts take the warm? The response is a mindful “yes”– with area to grow. They’re already holding their own in high-stakes fields, pushing the restrictions of what’s possible. As technology enhances, these published items could simply become the gold criterion for toughness and imagination.