Discover a professional 3D printing powder supplier

** Title: Can 3D Printed Steel Parts Make It Through the Real Life? Let’s Learn **.

(how strong are 3d printed metal parts)

Envision a cars and truck part that snaps under pressure or a rocket element that fractures mid-flight. Scenarios like these make people wonder: are 3D printed metal parts hard sufficient for real jobs? The solution isn’t easy. Allow’s go into the facts and see just how these advanced creations stand up.

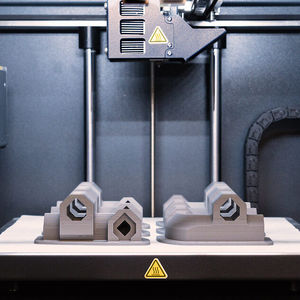

Initially, recognize how 3D printing steel functions. Unlike typical methods that cut or shape steel blocks, 3D printing builds things layer by layer utilizing lasers or electron beam of lights to thaw metal powder. This procedure, called “additive manufacturing,” lets engineers create complicated shapes impossible with older techniques. Typical steels utilized consist of titanium, stainless steel, and aluminum. These materials are preferred in aerospace, medical implants, and also customized bikes.

Now, the big question: stamina. Individuals usually presume 3D published parts are weaker due to the fact that they’re made in layers. However fact is a lot more interesting. The stamina depends upon three major variables: just how the layers stick, the quality of the metal powder, and the style of the component itself.

Layer bonding is critical. If the laser does not melt the powder completely, tiny voids or vulnerable points can develop. Consider it like cooking a cake. If one layer isn’t completely prepared, the whole cake may fall down. Advanced printers now make use of exact temperature level controls to fuse layers smoothly, developing components nearly as thick as strong metal.

Product quality matters as well. Low-cost or contaminated steel powder can cause splits or rust. Reputable producers examination every batch of powder for purity and grain dimension. Top quality powder means fewer defects and stronger components.

Layout plays a significant duty. Typical production restrictions forms to what drills or mold and mildews can take care of. 3D printing breaks these guidelines. Engineers can develop hollow frameworks, honeycomb patterns, or internal networks that conserve weight without sacrificing strength. A 3D published bracket might appear like a spiderweb, but it can hold even more weight than a strong block of metal.

So how do these parts contrast to created or cast steel? Studies reveal effectively published parts can match or even beat typical ones. For instance, Plane examined 3D printed titanium brackets in planes and found they handled stress and anxiety just as well as forged parts. GE utilizes 3D printed gas nozzles in jet engines, declaring they’re lighter and last longer.

Yet there’s a catch. Not all 3D published steels are equal. Printing settings, equipment calibration, and post-processing (like warmth treatment) make a large distinction. A part printed as well fast could have hidden problems. One printed too sluggish could warp from overheating. Experienced specialists tweak these variables to make sure reliability.

One more advantage? Less waste. Conventional machining carves away up to 90% of a metal block. 3D printing uses just the product needed, saving expenses and resources. This effectiveness is a huge deal for sectors like aerospace, where every gram counts.

Still, difficulties stay. High-end metal printers cost millions. Publishing a solitary component can take hours or days. Post-processing steps like polishing or layer add time. For little batches or prototypes, this works. For automation, standard methods are frequently quicker and less costly.

What about everyday uses? Companies are already checking 3D printed steel tools, dental implants, and even precious jewelry. A bike firm in Europe markets custom-made titanium frames printed to match a biker’s body. Medical professionals use 3D published cobalt-chrome hips due to the fact that they fit individuals much better than conventional sizes.

The greatest difficulty is trust. Individuals see 3D printing as experimental. However qualifications from groups like the FAA and ISO are altering that. These criteria guarantee printed components meet stringent safety demands. With proper screening and high quality checks, 3D metal parts are earning their place in vital applications.

(how strong are 3d printed metal parts)

So, can they survive the real life? Absolutely. The tech isn’t magic, but when done right, it’s a game-changer. From rockets to replacement knees, 3D published steel is proving it’s not just solid sufficient– it’s opening doors to advancements we’re just starting to explore.