Discover a professional 3D printing powder supplier

Unlocking the Magic: How to 3D Print Metallic Wonders

(how to 3d print metallic)

People talk a lot about 3D printing plastic toys and prototypes. But what about printing things made of real metal? That sounds like science fiction, right? It’s not. Metal 3D printing is here, and it’s changing how we make things. Forget the old image of noisy factories and hot forges. This is the future of making strong, complex metal parts. Let’s dive into this fascinating world.

1. What is Metal 3D Printing?

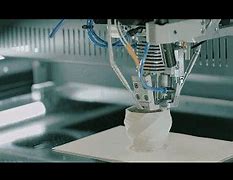

Metal 3D printing, or additive manufacturing, builds solid metal objects layer by layer. It’s not like your desktop plastic printer. Think lasers, high temperatures, and powdered metal. A computer guides a powerful laser or electron beam. This beam melts or fines metal powder, precisely where it needs to solidify. Layer upon layer gets added, building the final part from the bottom up. The main methods include Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). Each uses a focused energy source to melt metal powder. The powder is usually very fine, like dust. Common metals used are stainless steel, titanium, aluminum alloys, and even super-strong stuff like Inconel. It’s complex tech, but the result is a solid metal part made directly from a digital design.

2. Why Choose Metal 3D Printing?

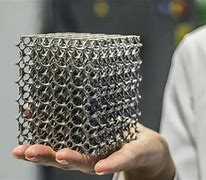

Why go through this high-tech process? Traditional methods like machining or casting have limits. Metal 3D printing offers unique advantages. First, it allows incredible design freedom. You can make shapes impossible with other methods. Think complex lattices, internal channels, and intricate geometries. This freedom leads to lighter, stronger parts. Second, it’s great for complex, low-volume parts. Need just one special component? Printing it might be faster and cheaper than setting up traditional tooling. Third, it can combine multiple parts into one. This simplifies assembly and reduces potential failure points. Fourth, it uses material efficiently. Unlike machining away a big block, printing adds material only where needed, reducing waste. Finally, it enables rapid prototyping and production for specialized applications. It brings metal parts closer to the speed and flexibility of plastic printing, but much stronger.

3. How Does Metal 3D Printing Work?

The process is precise. It starts with a 3D digital model, sliced into thin layers by software. Inside the printer, a chamber fills with an inert gas like argon or nitrogen. This prevents the hot metal from reacting with oxygen. A thin layer of metal powder spreads across the build platform. A powerful laser or electron beam scans the powder bed. It follows the pattern for that specific layer, melting the powder particles together. The build platform lowers slightly. Another layer of powder spreads over the first. The laser melts the new layer, bonding it to the one below. This repeats hundreds or thousands of times until the part is complete. After printing, the part is still encased in unused powder. Operators remove the build platform and extract the part. Post-processing is critical. This usually involves removing support structures, heat treatment for strength, and surface finishing like sandblasting or machining. The entire process requires careful control of temperature, gas flow, and laser power.

4. Cool Applications of Metal 3D Printing

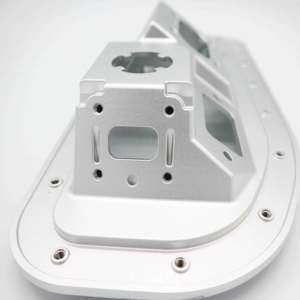

This tech isn’t just for labs anymore. It’s making real things in exciting fields. Aerospace loves it. Companies print lightweight, strong components for jets and rockets. Think fuel nozzles, turbine blades, and complex brackets impossible to cast. The medical field benefits hugely. Surgeons use custom-printed titanium implants shaped perfectly for a patient’s bone. Dentists create crowns and bridges faster. Automotive companies use it for prototyping and making high-performance parts, like custom engine components or lightweight brackets. Even the energy sector uses it for tough parts in oil, gas, and power generation equipment. Jewelers are exploring it for intricate designs in precious metals. Toolmakers print custom jigs, fixtures, and molds with internal cooling channels. It’s finding uses everywhere strength, complexity, and customization matter.

5. Metal 3D Printing FAQs

Many people have questions about this technology. Here are some common ones:

Is it affordable? It can be expensive. The printers cost hundreds of thousands to millions. The metal powders are pricey. For simple parts in large quantities, traditional methods are often cheaper. But for complex, custom, or low-volume parts, it can be cost-effective overall.

Is it safe? Printing happens inside sealed chambers with inert gas. Operators handle fine powders safely. Proper ventilation and protective gear are essential. The process generates heat, so thermal management is key. Following safety protocols is crucial.

How strong are the parts? Properly printed and post-processed parts can be very strong. They often match or exceed the strength of traditionally made parts from the same metal. The quality depends heavily on the machine, the material, and the print settings.

What metals can be printed? Many! Common ones include stainless steels (like 316L, 17-4 PH), titanium alloys (like Ti-6Al-4V), aluminum alloys (like AlSi10Mg), nickel-based superalloys (like Inconel 625, 718), cobalt-chrome, and even some precious metals like gold and silver.

Can I do this at home? Not really. Desktop metal printers exist but are still expensive and complex. They require significant expertise, safety measures, and post-processing equipment. It’s not like plug-and-play plastic printing. It’s mainly an industrial technology for now.

(how to 3d print metallic)

Metal 3D printing is powerful. It unlocks new ways to design and build. It moves us beyond the limits of traditional manufacturing. The ability to create complex, strong metal parts directly from a computer file is revolutionary. It’s not magic, but it’s pretty close. This technology keeps evolving, becoming faster, more reliable, and accessible. It’s reshaping industries and opening doors to innovations we haven’t even imagined yet. Keep an eye on metal 3D printing; it’s the superhero of modern manufacturing.