Discover a professional 3D printing powder supplier

Unlock the Magic: Crafting Steel with Your 3D Printer

(how to 3d print with metal)

Steel 3D printing transforms digital desires right into solid metal objects. This modern technology constructs complicated components layer by layer. It utilizes metal powders and high-powered warmth resources. Industries now produce once-impossible geometries. Hobbyists check out new frontiers. Let’s dive into steel’s 3D change.

1. What is Steel 3D Printing?

Steel 3D printing constructs items from powdered steels. It thaws fragments with lasers or electron light beams. Layers fuse together to create solid structures. This process is called additive manufacturing. It differs from carving steel blocks. No hammers or blades needed. Typical strategies include DMLS and SLM. DMLS means Direct Steel Laser Sintering. SLM stands for Careful Laser Melting. Both utilize great steel powders. Stainless steel, titanium, aluminum job best. Printers range from desktop units to commercial titans.

2. Why Choose Steel 3D Printing?

Steel printing addresses conventional production migraines. It produces hollow structures inside solid steel. Weight goes down without losing toughness. Aircraft components end up being lighter. Rockets fly farther. Modification is effortless. Dental experts publish distinct oral implants. Doctors make patient-specific bone plates. Waste reduces dramatically. Traditional machining remove 80% product. 3D printing wastes under 5%. Rate is an additional advantage. Models take hours as opposed to weeks. Production scales quickly.

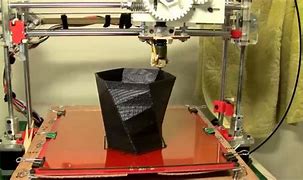

3. How Does Steel 3D Printing Job?

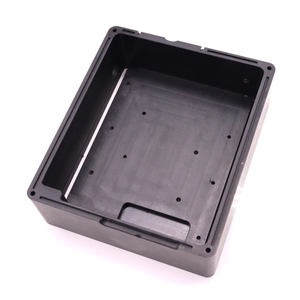

The procedure starts electronically. Layout your version making use of CAD software program. Cut it right into slim layers. Tons metal powder right into the printer. A wiper spreads out powder throughout the build plate. Lasers struck precise areas. Metal melts and solidifies quickly. Home plate decreases a little. New powder spreads over it. Lasers melt the next layer. This repeats hundreds of times. Assistance structures hold overhanging attributes. After printing, get rid of the part from the powder bed. Wipe excess powder. Heat-treat the piece for additional stamina. Complete surfaces by fining sand or brightening. Safety and security matters. Metal powders can blow up. Printers make use of argon gas to avoid fires.

4. Applications of Metal 3D Printing

Aerospace leads the charge. SpaceX publishes rocket engine parts. Complicated fuel nozzles carry out better. Weight financial savings cut fuel prices. Clinical implants transform lives. Cobalt-chrome knee replacements fit completely. Permeable titanium spine cages fuse with bone. Automotive business race in advance. Bugatti evaluates titanium brake calipers. Personalized gearshift handles personalize supercars. Jewelers craft detailed gold pendants. Mold makers installed air conditioning channels inside devices. Factories print unusual substitute components promptly. Artists form difficult metal geometries.

5. Metal 3D Printing FAQs

Q: Is published metal strong?

A: Yes. Properly published parts match built metal stamina. Titanium aerospace parts take care of severe stress and anxiety.

Q: What steels work best?

A: Stainless-steel dominates. Titanium fits clinical uses. Light weight aluminum saves weight. Copper prints warmth exchangers.

Q: Just how expensive is it?

A: Industrial printers cost over $100,000. Desktop versions start at $50,000. Solution bureaus cost per cubic centimeter.

Q: Can I publish big objects?

A: Industrial printers take care of briefcase-sized parts. Larger jobs join published areas.

Q: What prevail problems?

A: Buckling occurs if layers cool unevenly. Powder contamination creates weak spots. Assistance elimination leaves marks.

(how to 3d print with metal)

Metal 3D printing improves production. It transforms creative imagination right into concrete steel. Design flexibility blows up. Manufacturing cycles reduce. From garage tinkerers to , metal printing unlocks new worlds.