Discover a professional 3D printing powder supplier

Transform Plastic Dreams right into Steel Reality: The Ultimate Guide to Casting 3D Prints

(how to cast 3d prints in metal)

1. What is Casting 3D Prints in Steel?

Casting 3D prints in metal transforms plastic models right into strong steel items. You begin with a 3D published part. This part becomes a theme for a mold and mildew. Molten metal fills up the mold and mildew. After cooling down, you break away the mold material. What stays is a steel replica of your original print. This procedure combines electronic design with old metalworking. It transforms lightweight plastic into durable, heavy steel. Think of it as state-of-the-art alchemy.

2. Why Cast 3D Prints in Metal?

Plastic has limitations. It cracks under pressure. It melts near warmth. Metal resolves these problems. Casting provides you steel parts without buying a metal 3D printer. Steel printers set you back countless bucks. Casting usages economical devices. You obtain toughness and long life. Metal components handle engines, devices, or exterior wear. They look specialist. A plastic gear really feels cheap. A bronze gear feels industrial. Metal likewise withstands corrosion. You open new applications. Fashion jewelry put on weight and luster. Prototypes endure real-world testing. It’s cost-effective for one-off tasks.

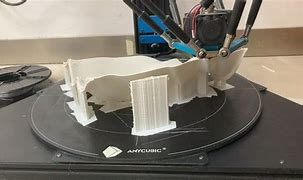

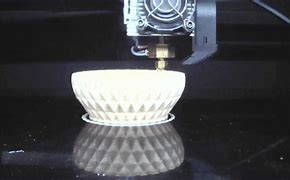

3. Exactly How to Cast 3D Prints in Metal: A Detailed Trip

Initially, layout your 3D design. Prevent slim walls. Include vents and sprues. These networks help steel flow. Print the model in PLA or resin. Sand it smooth. Next off, develop a mold and mildew. Use financial investment powder blended with water. Put this slurry around your print inside a steel flask. Allow it solidify overnight. Now, burn out the plastic. Warmth the flask in a kiln to 1300 ° F. The plastic evaporates. This leaves a hollow tooth cavity. Thaw your metal. Aluminum requires 1200 ° F. Bronze requires 1900 ° F. Usage a propane furnace. Put the liquified steel right into the mold and mildew dental caries. Use heat-resistant gloves and a face shield. Let the steel cool for hours. Damage the mold with a hammer. Eliminate your metal component. Cut off excess steel sprues. Sand and brighten the surface. Done.

4. Applications of Metal-Cast 3D Prints

Metal-cast 3D prints beam in real-world use. Custom fashion jewelry is a leading instance. Layout elaborate pendants in resin. Cast them in silver or gold. Artists shape detailed porcelain figurines. Bronze casting adds ageless value. Functional components prosper in engineering. Change busted device brackets. Develop lightweight light weight aluminum drone elements. Hobbyists build steam engine components. Metal deals with heat much better than plastic. Automotive remediations benefit. Vintage car handles recreated in brass. Also aerospace utilizes this. Test models for satellite installations. Clinical fields embrace it also. Surgical tools need sterile steel. Customized implants fit clients flawlessly. The key is personalization. Automation isn’t needed. One best steel item is sufficient.

5. FAQs on Casting 3D Prints in Steel

Q1: What steels work best for beginners?

A: Beginning with aluminum. It melts at reduced temperatures. Bronze is following. Avoid steel. It needs extreme warmth.

Q2: Can I utilize any 3D printer?

A: Yes. FDM printers with PLA work. Material printers catch finer details. Both burn out cleanly.

Q3: Is special equipment needed?

A: Fundamental tools include a heater, crucible, and security gear. Kilns help for financial investment spreading. Sand spreading uses less complex mold and mildews.

Q4: How comprehensive can the final steel part be?

A: Material prints attain 0.05 mm details. Steel duplicates these well. Surface area texture relies on mold and mildew quality. Polish enhances shine.

Q5: What security dangers exist?

A: Molten metal causes serious burns. Job outdoors. Use complete safety gear. Usage fire-resistant surfaces. Maintain a fire extinguisher nearby.

Q6: Why not just print in steel filament?

A: Metal filaments are plastic blended with powder. They look metallic yet do not have toughness. Real spreading creates strong metal.

Q7: How long does the procedure take?

(how to cast 3d prints in metal)

A: Printing takes hours. Mold setup needs over night curing. Casting and cooling down add an additional day. Persistence is essential.