Discover a professional 3D printing powder supplier

Steel Ink Magic: Your Overview to Packing Up for 3D Printed Steel

(how to load ink in any 3d printer print metal)

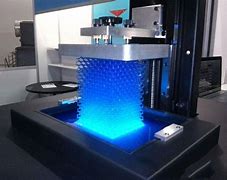

Ever check out a solid metal things and think, “Could I simply … print that?” The response is increasingly of course. Steel 3D printing is transforming exactly how we make points. But before you begin crafting small engine components or personalized fashion jewelry, you require the know-how to obtain the “ink” flowing. This isn’t your typical desktop computer printer ink. We’re discussing steel powder, the important ingredient for creating strong, functional steel parts layer by layer. Packing this specialized material appropriately is crucial. Allow’s dive into the world of metal ink and obtain you prepped for publishing success.

1. What Steel Ink Implies

Fail to remember fluid ink cartridges. In steel 3D printing, the “ink” is fine metal powder. Believe tiny grains, better than sand. Common steels include stainless steel, titanium, light weight aluminum, even tool steel and rare-earth elements like gold. The printer does not press this powder out of a nozzle like plastic. Instead, a powerful laser or electron beam uniquely melts the powder bits together, developing your object slice by piece from a bed of this material. So, filling ink implies carefully filling the printer’s develop chamber or powder supply system with this particular steel powder. It’s even more like filling resources than standard ink. Understanding this powder is key. Its size, form, and composition directly impact the quality of your final printed metal component. Making use of the incorrect powder, or managing it badly during packing, can bring about fallen short prints or weak outcomes. It’s the structure of your metal development.

2. Why Steel Ink Matters

Getting the steel powder filling action right is absolutely vital. Below’s why. Initially, uniformity is king. An unequal layer of powder in the develop chamber means the laser or beam won’t thaw equally. This leads to vulnerable points, warping, or the print falling short outright. Think about attempting to develop a brick wall surface on an uneven structure– it simply will not work well. Second, contamination is the enemy. Metal powders are sensitive. Even little bits of dirt, wetness, or oils from your skin can mess up the melting process. This contamination can cause porosity (tiny openings inside the steel), making the component weaker. Or it can transform how the metal acts under the warmth, once more resulting in fractures or failures. Third, safety and security. Numerous steel powders are responsive. Some can also be flammable under the best problems. Loading them meticulously minimizes the risk of spills, dust clouds, or accidental ignition. Correct handling secures you and the maker. Ultimately, metal powder is pricey. Wasting it through spills or fell short prints because of negative loading hurts your wallet. Doing it appropriate saves cash and material. Loading isn’t just a chore; it’s a crucial step for safety and security, high quality, and price.

3. Exactly How to Tons Steel Ink

Packing steel powder requires care and focus. While certain steps differ a little between printer brand names, the core principles are similar. Constantly begin by reviewing your printer’s handbook. Safety and security initially! Use the appropriate equipment: safety glasses, nitrile gloves, and typically a lab layer or protective garments. A respirator may be required for finer powders. Ensure your workspace is tidy and well-ventilated. Switch off the printer. Open up the build chamber or the designated powder packing port very carefully. Often, printers use secured containers or bags to move powder securely and lessen dust. Connect the container safely to the printer’s filling up system. Comply with the machine’s directions for initiating the fill process. This might involve shutoffs or automated systems. See the fill level meticulously. Overfilling can create troubles, much like underfilling. Many printers have sensing units, however hands-on checks are excellent. When filled, shut the system up firmly. Tidy any type of spilled powder promptly using authorized methods– generally unique vacuum made for steel powders, never ever brooms. Tape-record the kind of powder loaded and the quantity used. Shop any type of remaining powder in its original, closed container in a completely dry, refuge. Keep in mind, perseverance and accuracy are your ideal tools here.

4. Metal Ink Applications

Once packed and prepared, what can you actually make with metal 3D printing? The opportunities are growing fast. Aerospace firms use it for light-weight, complicated engine components and architectural elements. Think generator blades with intricate air conditioning channels difficult to make any other way. The medical field advantages extremely. Surgeons utilize published titanium for custom hip replacements, spinal implants, and even cranial plates customized flawlessly to a person’s composition. The auto market prints high-performance parts like custom pistons, light-weight brackets, and also elements for electrical automobiles. Jewelers develop spectacular, comprehensive pieces in gold, silver, and platinum utilizing this technology. Industrial makers depend on printed steel for robust jigs, components, and tooling components that endure heavy usage. Also research study labs print specialized equipment. The magic depend on creating intricate geometries, lowering waste contrasted to machining, and allowing quick prototyping and manufacturing of strong, functional metal parts directly from digital designs. Packing that powder appropriately opens this entire globe of technology.

5. Metal Ink Frequently Asked Questions

Allow’s deal with some typical inquiries about taking care of steel powder for 3D printing.

Can I make use of any steel powder? No. Printers are developed for certain powder kinds and sizes. Using the wrong one can harm the maker or develop risky conditions. Constantly utilize the powder advised by your printer supplier.

Is it dangerous? Some powders can be. Particular metals are poisonous if breathed in, others could respond with wetness or air. Constantly deal with the powder with regard. Comply with safety guidelines strictly. Usage appropriate PPE and dealing with treatments.

How much time does the powder last? Powder can degrade gradually, especially if subjected to dampness or air. Store it secured in a dry setting. Lots of printers reuse unused powder from around the published component, mixing it with fresh powder for the next work. However even recycled powder has a life expectancy before it requires changing.

Suppose I spill powder? Do not move it. Sweeping produces dust clouds. Utilize a specialized vacuum cleaner approved for metal powders, frequently with unique filters. Tidy the area extensively. Report substantial spills following your safety and security procedures.

(how to load ink in any 3d printer print metal)

Can I mix various powders? Usually, no. Blending powders usually causes unforeseeable outcomes and prospective contamination. Adhere to one kind per print job unless you have certain directions and a valid reason.