Discover a professional 3D printing powder supplier

Metal Matchmaking: Finding Your Perfect 3D Printing Partner

(how to pick your metal for 3d printing)

Choosing the right metal for your 3D printing project feels like matchmaking. It’s not just about what looks good. You need a partner that performs under pressure, handles the heat, and fits your budget. Get it wrong, your beautiful printed part might crack, warp, or simply fail its job. Get it right, you unlock incredible strength, complex designs, and real-world functionality. This guide cuts through the confusion. We explore the key players in the metal 3D printing world and how to pick your champion.

1. What Exactly is Metal 3D Printing?

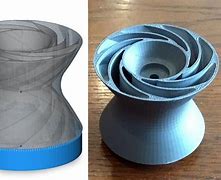

Forget plastic trinkets. Metal 3D printing builds solid, functional parts directly from digital designs using real metal powders. Think of it as welding, but controlled by a computer, layer by incredibly thin layer. The most common methods involve lasers or electron beams. A high-power beam selectively melts or sinters (fuses) tiny metal particles together, precisely following the part’s cross-section. After one layer finishes, the build platform lowers slightly. A fresh layer of powder spreads over the top. The beam goes to work again. This repeats hundreds or thousands of times until the complete part emerges from the powder bed. Other methods exist, like binding metal powder with glue then sintering it later, or directing energy jets to fuse metal powder as it’s deposited. The core idea remains: building complex metal shapes directly, often impossible with traditional machining or casting. It opens doors to lightweight structures, internal cooling channels, and custom one-off parts.

2. Why Metal Matters in 3D Printing

Not all metals are created equal. Your choice dramatically impacts what your printed part can actually do. The wrong metal leads to disaster. Imagine a jet engine turbine blade printed in a metal that melts too easily. Bad news. Metal selection dictates critical properties. Strength is obvious. Can it handle the load without bending or breaking? Heat resistance is vital for parts near engines or hot processes. How well does it conduct electricity or heat? This matters for electronics housings or heat exchangers. Corrosion resistance keeps parts functioning in harsh environments like chemical plants or saltwater. Biocompatibility is essential for medical implants. The metal must be friendly to the human body. Weight matters for aerospace and automotive applications. Every gram saved improves fuel efficiency. Finally, cost plays a huge role. Some exotic metals perform amazingly but cost a fortune. Others offer a good balance. Choosing the right metal ensures your printed part survives and thrives in its intended role.

3. How to Choose Your Metal Material

Picking your metal isn’t guesswork. It’s a deliberate process focused on your part’s job. Start with the application. What does this part need to do? List the non-negotiables. Does it need to be super strong? Resist high temperatures? Handle corrosive chemicals? Be lightweight? Conduct electricity? Be implanted in the body? Next, consider the printing process itself. Not all metals work well with all 3D printing methods. Some machines are optimized for specific alloys. Check compatibility with your chosen printer or service provider. Cost is always a factor. Balance performance needs against your budget. Exotic alloys like Inconel offer incredible properties but come with a hefty price tag. Common steels or aluminums are far more budget-friendly. Look at the powder characteristics too. Flowability and particle size distribution affect how well the powder spreads and melts during printing. Finally, think about post-processing. Will your part need heat treatment for extra strength? Machining for precise tolerances? Surface finishing for looks or corrosion protection? Some metals respond better to these treatments than others. Match the metal’s strengths to your part’s demands.

4. Metal 3D Printing Applications

Metal 3D printing isn’t science fiction. It’s solving real problems right now. Aerospace leads the charge. Companies print lightweight, complex brackets, fuel nozzles with intricate internal channels, and turbine blades designed for extreme heat and stress. These parts often weigh less than traditional ones, saving fuel. The medical field embraces it too. Surgeons implant patient-specific hip and knee replacements printed from biocompatible titanium. Dental labs create crowns and bridges. Researchers develop custom surgical tools. Automotive engineers use it for prototyping high-performance parts like custom intake manifolds or lightweight suspension components. Racing teams rely on it for bespoke, optimized components. The energy sector prints complex parts for oil and gas drilling equipment and heat exchangers. Toolmakers create injection molds with conformal cooling channels that drastically reduce cycle times. Jewelers craft intricate designs previously impossible. From rugged industrial tools to life-saving implants, metal 3D printing delivers functional solutions.

5. Metal 3D Printing FAQs

Let’s tackle some common questions about metal 3D printing materials.

Are 3D printed metal parts as strong as forged or machined ones? Yes, often stronger. The process allows for very fine microstructures. Properly printed and heat-treated parts can meet or exceed the strength of traditionally made equivalents. Testing confirms their mechanical properties.

What’s the most common metal used? Stainless steel, especially 316L and 17-4 PH, is incredibly popular. It offers a great mix of strength, corrosion resistance, and cost-effectiveness. It’s a reliable workhorse for many applications.

Is titanium really used? Absolutely. Titanium alloys like Ti6Al4V are prized for aerospace and medical implants. They are incredibly strong yet lightweight and biocompatible. The cost is higher than steel, but the performance justifies it for critical parts.

Can I print with regular metals like aluminum? Yes. Aluminum alloys, particularly AlSi10Mg, are widely printed. They are lightweight, reasonably strong, conduct heat well, and cost less than titanium or nickel alloys. Great for housings, heat sinks, and lightweight structures.

(how to pick your metal for 3d printing)

Are there any metals I absolutely cannot print? Pure copper is notoriously difficult with laser-based systems because it reflects the laser light so well. Special machines or processes are needed. Very high melting point metals like tungsten are also challenging but possible with specific electron beam methods. Research continues to expand the printable metal library.