Discover a professional 3D printing powder supplier

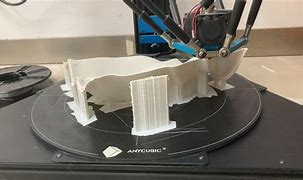

Title: Metal Magic: Exactly How Your 3D Printer Can Craft Solid Steel Creations .

(how to print metal in a 3d printer)

Main Item Keywords: Steel, 3D Printer.

1. Exactly What is Metal 3D Printing? .

Steel 3D printing seems like science fiction. It isn’t your standard plastic filament printer. This innovation builds real steel components layer by layer. Believe lasers, fine metal powder, and major warm. The objective is developing solid, functional steel objects directly from digital layouts. A number of methods exist. The most usual for serious job is Discerning Laser Melting (SLM) or Straight Steel Laser Sintering (DMLS). A high-powered laser beam of light melts small fragments of metal powder together. It traces the shape of one thin layer. After that fresh powder spreads over it. The laser melts the following layer. This repeats until the whole steel part kinds inside a chamber full of inert gas. It’s accurate. It’s effective. It opens geometries impossible with conventional metalworking.

2. Why Bother Printing Steel? What’s the Big Bargain? .

Traditional steel construction has restrictions. Machining cuts away product. This wastes pricey metal. It battles with complicated inner networks or complex latticework frameworks. Casting needs mold and mildews. Mold and mildews are expensive and slow-moving to make. Metal 3D printing addresses these troubles. It develops components additively. Only the necessary metal obtains utilized. Waste is very little. Facility styles are simple. Visualize a cooling flow inside a generator blade. It weaves. Machining this is virtually impossible. Publishing it is simple. Components can be lighter yet more powerful. Optimized internal frameworks achieve this. Prototyping speeds up dramatically. Need a customized metal brace? Design it. Publish it. Test it. All in days, not weeks. Small set production comes to be cost-effective. No enormous tooling financial investment needed.

3. How Does Steel 3D Printing Really Function? Step-by-Step .

The procedure demands specialized devices and treatment. Below’s the core workflow utilizing powder bed blend (like SLM/DMLS):.

Layout: Everything starts with a 3D CAD model. Software slices this design into ultra-thin horizontal layers.

Prep the Maker: The printer chamber gets full of an inert gas like argon. Oxygen is bad. It can oxidize the warm steel. A thin layer of great metal powder tops the construct system.

Laser Melting: A powerful laser scans the very first layer’s cross-section. It uniquely thaws the metal powder bits, fusing them with each other precisely.

Lower & Recoat: The construct system lowers slightly. A fresh layer of powder spreads over the strengthened layer.

Repeat: The laser scans and melts the following layer. It bonds to the layer listed below. This cycle continues. Layer by layer, the metal object grows inside the powder bed.

Cool: After publishing surfaces, the whole build chamber cools down slowly. Quick air conditioning emphasizes the metal.

Post-Processing: This is critical. The published part is buried in unused powder. Employees very carefully eliminate it. Support structures (often printed as well) need elimination. The part typically requires heat treatment (stress and anxiety alleviating, annealing, or hot isostatic pressing – HIP). This boosts strength and minimizes internal anxieties. Lastly, surface ending up like machining or polishing happens. This accomplishes the preferred feel and look.

4. Where is Metal 3D Printing Making Waves? Actual Applications .

This tech isn’t just for labs anymore. It’s changing markets requiring solid, complicated, or custom steel parts:.

Aerospace & Protection: Generator blades, gas nozzles with inner networks, light-weight structural braces, heat exchangers. Weight cost savings right here mean huge gas efficiency gains.

Medical & Dental: Patient-specific implants (hip, knee, spinal), medical guides, oral crowns and bridges. The customized fit improves outcomes.

Automotive: Lightweight elements, complicated consumption manifolds, customized auto racing parts, efficiency thermal barrier. Rate and performance drive adoption.

Tooling & Production: Conformal air conditioning networks inside shot mold and mildews. These trendy plastic components faster and extra equally. Outcome? Shorter cycle times and far better top quality components. Jigs and fixtures tailored for certain assembly tasks.

Power: Facility parts for oil & gas removal, heat exchangers for power generation, components for next-gen nuclear systems. Toughness in extreme environments is vital.

High-End Design: Prototypes for intricate systems, custom robotics components, research study devices elements. Flexibility is the advantage.

5. Metal 3D Printing FAQs: Your Burning Concerns Responded To .

Can I use my home FDM printer for steel? Not actually. Real metal printing requires specialized, expensive makers. Some business provide metal-infused filaments. You print with these on a basic FDM printer. The printed part is “green.” It needs cautious debinding and sintering in a heater. The last component diminishes dramatically. It’s porous. It does not have the stamina of real printed steel. Believe “metal-like” rather than solid steel.

Is printed metal solid? Absolutely. Appropriately processed SLM/DMLS components can attain mechanical residential or commercial properties near and even surpassing commonly cast or functioned metal. Post-processing like HIP is vital for high-performance applications.

What steels can be printed? Numerous! Usual ones consist of stainless steels (316L, 17-4 PH), titanium alloys (Ti6Al4V), aluminum alloys (AlSi10Mg), nickel-based superalloys (Inconel 718, 625), cobalt-chrome, and tool steels. Study continues adding extra alloys.

Is it risk-free? Steel powder handling needs rigorous safety protocols. Great steel powders are flammable and explosive. Breathing risks exist. Printing takes place in secured chambers with inert gas. Operators need training. Correct ventilation and PPE are non-negotiable.

(how to print metal in a 3d printer)

Just how pricey is it? Expenses are high. The printers cost numerous thousands. Metal powders are expensive. Post-processing includes even more price. It makes good sense for complicated components, reduced quantities, or applications where performance justifies the rate. Prices are reducing as modern technology matures.