Discover a professional 3D printing powder supplier

Title: Steel Magic: Publishing Strong Metal on Your 3D Printer .

(how to print metal on a 3d printer)

Main Item Keywords: Metal 3D Printing.

1. What is Steel 3D Printing? .

Steel 3D printing seems like sci-fi. It develops real, solid steel items directly from a digital file. Neglect plastic ornaments. This constructs practical metal components. Believe equipments, tools, also custom-made jewelry. The process makes use of steel powder as its ink. Unique printers bind this powder layer by layer. Warm then merges it into solid steel. The major methods are binder jetting and metal extrusion. Binder jetting sprays a glue-like binder onto metal powder. Steel extrusion utilizes filaments packed with metal fragments. Both require a last step: sintering. Sintering cooks the component in a heater. This burns away the binder or plastic. It leaves just pure, dense metal behind. This isn’t your ordinary desktop printing. It calls for specific printers and cautious steps. The result is genuine metal.

2. Why Pick Steel 3D Printing? .

Standard metalworking is tough. Machining remove metal. It wastes product. Casting demands complicated molds. It takes time and cash. Metal 3D printing supplies different advantages. Initially, it makes complex forms quickly. Inner networks, hollow structures, complex latticeworks. These are basic for 3D printing. Machining or casting struggles with them. Second, it makes use of material effectively. You only use the steel needed for the part. Much less waste occurs. Third, it makes it possible for fast prototyping. Design a steel part today. Print and examine it tomorrow. This speeds up advancement greatly. 4th, it enables personalization. Make one unique piece. Or make small sets. Both are cost-efficient. Fifth, it incorporates parts. Publish assemblies as one solitary piece. This minimizes setting up steps. It boosts strength. For facility, custom, or low-volume steel parts, this method beams.

3. Just How Does Steel 3D Printing In Fact Work? (Concentrate On Desktop Computer Techniques) .

You want metal parts on your desktop printer? 2 primary courses exist: Bound Metal Deposition and Sintering. Right here’s the breakdown:.

Bound Metal Deposition (BMD): This makes use of unique filament. It looks like regular 3D printer plastic. Inside, it’s packed with little metal powder (like stainless steel, copper, or bronze). You print the things on your typical FDM printer. It seems like a breakable “eco-friendly” component. The actual magic takes place next off. You put this part in a debinding solution. This washes away a lot of the plastic binder. After that, it goes into a high-temperature sintering heating system. Sintering heats up the part near its melting point. The steel bits fuse together. The staying binder burn. The part diminishes significantly (around 20%). It becomes a solid steel things. Density gets to over 90% of solid steel. Firms like BASF (Ultrafuse) and The Online Foundry make these filaments.

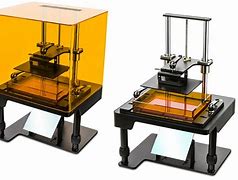

Metal Binder Jetting (Needs Unique Printer): Desktop variations are arising. A great layer of metal powder spreads throughout the develop system. An inkjet print head sprays tiny beads of liquid binder. This binder adhesives the metal bits with each other. Layer by layer, the object forms. It’s still delicate. This “green” part then experiences debinding and sintering. The procedure resembles BMD. The binder is eliminated. The steel particles sinter right into a strong mass. The final part is dense steel. Printers like the Desktop Computer Metal Workshop System work by doing this. This approach uses finer detail than BMD filament.

Security is vital. Metal powder is harmful. Sintering demands extremely high warm. Always follow the producer’s guidelines. Usage correct air flow. Take care of powders very carefully.

4. Applications: Where Does Metal 3D Printing Beam? .

Steel 3D printing isn’t just amazing. It addresses genuine issues throughout lots of fields:.

Aerospace & Automotive: Weight issues here. Complex, light-weight metal brackets. Optimized heat exchangers. Customized engine parts. Prototyping parts quick conserves big prices.

Medical & Dental: Biocompatible steels like titanium are excellent. Custom-made medical guides fit a patient completely. Oral crowns and bridges print quickly. Implant models are simple to make.

Tooling & Manufacturing: Jigs and components break. Publish personalized substitutes quickly. Shot mold and mildews with conformal cooling networks. These networks follow the mold shape. They cool down components quicker. This improves manufacturing speed and top quality.

Robotics & Automation: Resilient equipments, joints, and customized sensing unit installs. Publish strong, intricate components robots require. Repair busted steel elements promptly.

Art, Jewelry & Collectibles: Design liberty is unparalleled. Produce elaborate metal sculptures difficult by hand. Publish custom-made rings or pendants in rare-earth elements. Make unique collectible figures in solid steel. This opens up brand-new creative doors.

5. Metal 3D Printing FAQs: Your Burning Concerns Responded To .

Q1: Is it REALLY solid metal? Yes. After sintering, the component is strong steel. It’s not just layered plastic. The binder and plastic carrier are totally gone. Steel bits fuse with each other. Density is high. Toughness is genuine.

Q2: How strong are these published steel components? Strength depends on the metal and the procedure. Sintered parts get to near-wrought steel toughness. They are practical. They handle genuine loads. They are not constantly as strong as forged metal. For lots of applications, it’s solid sufficient.

Q3: What metals can I print? Typical desktop computer alternatives include Stainless Steel (316L, 17-4PH), Tool Steel, Copper, Bronze, and Titanium. Accessibility depends upon the filament or powder provider. Industrial makers use even more alloys.

Q4: Is this safe to do at home? Caution is vital. Steel powders are a breathing danger. Use handwear covers and masks. Deal with powders in controlled environments. Sintering needs high temperatures (often over 1300 ° C/2372 ° F). Utilize a dedicated, well-ventilated sintering furnace. Follow all safety standards strictly. It’s not like printing PLA.

(how to print metal on a 3d printer)

Q5: How pricey is steel 3D printing? Prices are greater than plastic printing. Special filament or powder prices more. You require a sintering heating system. Heaters are a significant financial investment. Consider material waste and power usage. For intricate models or custom components, it can be affordable. For automation, standard methods are normally less expensive.