Discover a professional 3D printing powder supplier

From Rough to Fantastic: Your No-Fuss Guide to Polishing Steel 3D Prints

(how to smooth a metal 3d print)

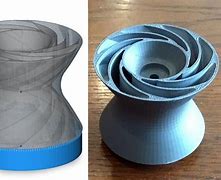

Allow’s be sincere– steel 3D prints don’t always appear looking prepared for the spotlight. Harsh sides, visible layers, and uneven structures can make even the coolest design appear a little bit … unfinished. However do not panic. With a couple of standard methods, you can transform that bumpy metal mess right into something smooth and expert. Below’s how.

** Begin with Sanding **.

Sanding is your very first step. Consider it like filing down a harsh diamond. Get some sandpaper– start with coarse grit (around 80-120) to take on large bumps or layer lines. Rub it over the surface in tiny circles. Press hard sufficient to remove flaws but not so difficult you warp the form. Switch to finer grits (200-400) when the worst defects are gone. This smooths things additionally and preps the surface area for other methods. Pro pointer: Damp sanding (utilizing water or oil with the sandpaper) reduces dust and offers a cleaner surface.

** Attempt Grinding for Tough Places **.

Some locations are as well stubborn for sandpaper alone. That’s where grinding tools can be found in. A rotating device with a grinding little bit lets you focus on tiny gaps or tight corners. Work gradually. Steel heats up fast, and excessive friction can harm the print. Keep the device transferring to avoid developing brand-new grooves. If you fidget, practice on scrap prints first.

** Chemical Smoothing Magic **.

Chemicals aren’t just for laboratories. For steel prints, acid-based services like nitric acid or specialized dips can dissolve microscopic roughness. Dip the print into the remedy for a few seconds, then rinse completely with water. Safety initially: Wear handwear covers and safety glasses. Evaluate the chemical on a small location first– some metals react differently. This approach works best for detailed layouts where sanding is not practical.

** Warm It Up (Very Carefully) **.

Warmth treatment isn’t simply for toughness. A controlled blast from a lantern or a kiln can melt surface blemishes. Make use of a low fire and move it evenly throughout the print. Watch very closely– overheating reasons deforming or discoloration. This method is high-risk yet fulfilling if done right. Exercise on examination pieces up until you nail the timing and temperature.

** Toppling for Attire Shine **.

Ever before seen a rock brush? Rolling works similarly. Toss your print into a vibrating container filled with abrasive media like ceramic pellets or steel shot. Allow it shake for hours. The constant rubbing enthusiasts the surface area equally, perfect for complicated forms. Various media provide different surfaces– experiment to discover your favorite.

** Seal the Deal **.

Once smooth, secure your work. Clear metal sealants or lacquers add a shiny surface and protect against corrosion. Spray a slim, also coat and allow it dry entirely. Want extra sparkle? Usage metal gloss and a soft towel to buff the surface till it beams.

** Persistence Settles **.

None of these techniques are immediate. Hurrying results in errors. Take breaks. Inspect the print under bright light to find missed out on spots. Mix methods– sand initially, after that tumble, after that seal. Every print is various, so adapt your method.

(how to smooth a metal 3d print)

Metal 3D printing opens doors to wild layouts, however completing is what transforms “meh” into “wow.” Grab your devices, welcome the mess, and remember: Even the shiniest masterpiece began as an outline.