Discover a professional 3D printing powder supplier

Is Metal 3D Printing the Future of Fabrication?

(how well does 3d printing work with metal)

Metal 3D printing sounds like something straight out of science fiction. Printing solid metal objects layer by layer? It seems almost magical. But it’s very real, and it’s rapidly changing how we make things. This technology isn’t just a novelty anymore. It’s becoming a powerful tool in industries from aerospace to medicine. So, let’s dive in and see what all the excitement is about.

1. What Exactly is Metal 3D Printing?

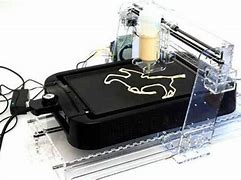

Think of metal 3D printing as a super-precise welding torch controlled by a computer. Instead of ink, it uses fine metal powder or wire. Instead of a printer head, it uses a high-powered laser, electron beam, or even a binder jetting system. The machine reads a digital 3D model, slicing it into incredibly thin layers. Then, it builds the object one layer at a time, fusing the metal together. This process has several names. You might hear it called metal additive manufacturing (AM), direct metal laser sintering (DMLS), selective laser melting (SLM), or binder jetting. Each method has its own quirks, but the core idea is the same: building complex metal parts directly from a digital file, adding material only where needed. This is a big shift from traditional machining, which cuts away material from a solid block. It allows for shapes and internal structures that were once impossible to make.

2. Why Choose Metal 3D Printing?

Traditional metalworking methods like casting or machining have served us well for centuries. So why switch to 3D printing? The reasons are compelling. First, it offers incredible design freedom. Engineers are no longer limited by what a cutting tool can reach or a mold can release. They can create parts with intricate lattices, internal channels, or organic shapes that optimize strength and minimize weight. Think about aerospace parts – saving weight without sacrificing strength is crucial. Second, metal 3D printing excels at making complex parts as a single piece. Parts that used to require welding or bolting multiple components together can now be printed whole. This reduces potential failure points and simplifies assembly. Third, it can be more efficient with materials. Since you only use the metal needed for the part itself (and some support structures), there’s far less waste compared to machining away a large block. Finally, for low-volume production or custom one-off parts, metal 3D printing is often faster and cheaper than setting up traditional tooling like molds. This makes it ideal for prototypes, bespoke medical implants, or specialized tooling.

3. How Does Metal 3D Printing Actually Work?

While different technologies exist, let’s look at two common ones: Powder Bed Fusion and Binder Jetting. In Powder Bed Fusion (like DMLS or SLM), a thin layer of fine metal powder is spread across a build platform. A powerful laser or electron beam then scans across the powder, selectively melting it according to the digital slice of the part. Once a layer is done, the platform lowers slightly, a new layer of powder is spread, and the process repeats. The part is built inside a bed of powder, which supports it during printing. After printing, the whole build chamber cools down. The unused powder is removed and recycled. The printed part is then taken out. It often still has support structures attached. These supports are crucial. They anchor the part to the build plate and prevent warping as the metal cools. Removing these supports requires careful cutting or machining. The part might also need heat treatment (like an oven bake called annealing) to relieve internal stresses and improve its strength. Finally, surface finishing steps like polishing or sandblasting give it the desired look and feel. Binder Jetting works differently. Here, a print head (like an inkjet nozzle) deposits a liquid binding agent onto a layer of metal powder. This binder glues the powder particles together in the shape of the part. The build platform lowers, more powder is spread, and the process continues layer by layer. After printing, the part is still fragile, made of glued-together powder. It goes into a furnace for sintering. Sintering heats the part just below the melting point of the metal. This causes the particles to bond together permanently, and the binder burns away. Sintered parts are dense and strong, though they might shrink slightly.

4. Where is Metal 3D Printing Used Today?

The applications are expanding rapidly. Aerospace companies love it. They use it to make lightweight, complex components for jet engines, satellites, and rockets. Think turbine blades with internal cooling channels or fuel nozzles impossible to machine conventionally. The medical field is another big user. Surgeons can now get custom titanium implants – hip joints, spinal cages, or cranial plates – perfectly shaped for an individual patient. This leads to better fits and faster recoveries. The dental industry uses it for crowns, bridges, and orthodontic devices. Automotive companies use metal 3D printing for high-performance parts in racing cars. They also use it to create custom tools and jigs used on the assembly line. Even the energy sector benefits. Oil and gas companies print unique drill bits and components that withstand extreme underground pressures and temperatures. Turbine manufacturers create complex parts for power generation. Beyond these, the technology is finding uses in making custom jewelry, intricate heat exchangers, and even components for consumer electronics. As machines become faster and materials more affordable, its reach will only grow wider.

5. Metal 3D Printing FAQs: Your Burning Questions Answered

(how well does 3d printing work with metal)

Is it strong? Yes! Properly printed and processed metal parts can be just as strong, sometimes even stronger, than traditionally made counterparts. They meet demanding industry standards. How much does it cost? It depends. The printers themselves are expensive, and metal powder isn’t cheap. For simple parts made in large quantities, traditional methods might be cheaper. But for complex, custom, or low-volume parts, metal 3D printing often wins on cost. What metals can you print? A growing list! Common ones include titanium (great for medical and aerospace), stainless steel (versatile and strong), aluminum (lightweight), nickel alloys (heat resistant), cobalt-chrome (biocompatible for implants), and even precious metals like gold and silver. New materials are constantly being developed. Are the parts smooth? Not always straight off the printer. Parts often have a slightly rough surface from the layered process or sintered texture. Post-processing like machining, polishing, or blasting is usually needed for a smooth finish. This adds to the time and cost. Is it fast? Printing itself can take hours or even days for large, complex parts. The whole process includes design, printing, support removal, heat treatment, and finishing. So, it’s not instant. But for complex parts, the total time from design to finished part can still be faster than traditional methods involving tooling setup. How precise is it? Very precise. Modern machines can achieve details and tolerances suitable for demanding engineering applications. The level of precision depends on the technology and the specific machine used.