Discover a professional 3D printing powder supplier

Steel 3D Printing: Budget Plan Innovation or Simply Hype?

(id 3d metal printing cheaper than the normal way?)

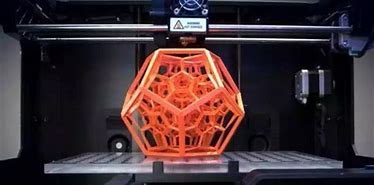

Picture printing cars and truck components like records. Steel 3D printing makes this feasible. Individuals call it cutting edge. But is it in fact less expensive than old means? That’s the huge question. Let’s go into the real expenses.

1. What is Steel 3D Printing? .

Steel 3D printing constructs objects layer by layer. It makes use of lasers or electron beam of lights. These melt metal powder to form shapes. It’s not like normal printing. Think about it as high-tech welding. A computer system controls the entire procedure. This permits complicated shapes impossible before. Usual approaches consist of DMLS and SLM. These fuse great metal powders. One more method binds powders with adhesive first. Then it sinters them in an oven. Metal 3D printing provides design freedom. It minimizes waste dramatically. Traditional machining remove material. 3D printing includes product just where needed. This is a huge distinction.

2. Why Take Into Consideration Metal 3D Printing Price? .

Expense issues for any type of service. Metal 3D printing can conserve cash in specific situations. The main cost savings come from less waste. Typical machining starts with a strong block. It cuts away as much as 90% of the product. That’s pricey steel thrown away. 3D printing uses only the powder needed. This reduces product expenses a great deal. Configuration expenses are lower as well. Making mold and mildews for casting costs thousands. It takes weeks. 3D printing requires minimal configuration. Simply pack the electronic data. This suggests much faster start times. For little batches, it’s frequently cheaper. It allows complex components unharmed. This reduces setting up expenses. No need for multiple components and bolts. Tooling prices vanish. You don’t require unique fixtures or mold and mildews. This makes low-volume production budget-friendly. Preparations reduce dramatically.

3. How to Make Metal 3D Printing Cheaper? .

Making metal 3D printing cheaper entails wise selections. First, style especially for it. Use geography optimization. This software program creates strong shapes utilizing very little product. Burrow inner sections. Include lattices inside parts. This keeps strength while decreasing weight and material. Choose the right metal powder. Criterion alloys set you back much less than exotic ones. Inconel is pricier than stainless-steel. Optimize component placement inside the equipment. Nest components successfully. Pack as several as possible per develop. This spreads the device cost. Take into consideration the entire manufacturing circulation. In some cases publishing near-net shapes helps. Then completed with light machining. This equilibriums rate and accuracy. Collaborate with seasoned company. They recognize exactly how to optimize maker usage. They prevent failed builds losing cash. Invest in high quality powder handling. Reusing unused powder cuts prices. Good systems permit high reuse rates. Correct storage avoids dampness. This keeps powder good longer.

4. Applications Where Steel 3D Printing Saves Cash .

Where does metal 3D printing beat conventional prices? Aerospace is a huge champion. Components are light and complex. Saving weight conserves fuel. Fuel costs are big gradually. Printing fuel nozzles as one piece is common. It changes several welded parts. This is more affordable and extra reputable. Clinical implants profit too. Custom-made hip joints fit people perfectly. Standard methods have problem with personalization. 3D printing manages it easily. Expense per custom-made component drops. Tooling for production is another location. Making shot mold and mildews takes weeks. Steel 3D printing makes them faster. It permits conformal cooling channels. These trendy plastic components quicker. Faster cycles imply even more components per hour. This conserves money. Fixing high-value parts functions well. Repairing generator blades is costly. Printing metal onto harmed locations restores them. This costs much less than full substitute. Prototyping complex parts saves cash money. Faster versions suggest quicker choices. Getting to market quicker is cheaper.

5. Metal 3D Printing Price Frequently Asked Questions .

(id 3d metal printing cheaper than the normal way?)

Individuals ask several questions about prices. Is steel 3D printing cheaper than CNC machining? In some cases. For straightforward shapes in big sets, CNC wins. For complicated components in small numbers, 3D printing is better. Just how much does the steel powder expense? It varies. Common steels cost $50-100 per kg. Titanium sets you back $200-400 per kg. Special alloys set you back more. Is the maker cost high? Yes. Industrial equipments cost $500,000 to over $1 million. This requires high volume to validate. However service bureaus use gain access to without buying. What concerning component high quality? It’s excellent now. Printed parts match forged metal toughness. Surface surface may need polishing. Can I publish large parts? Makers are getting bigger. Publishing meter-sized parts is possible currently. Cost per part scales with size. Huge parts cost even more powder and time. Is it safe? Dealing with great powders needs care. Good systems take care of dust and fumes. Operators wear safety gear.