Discover a professional 3D printing powder supplier

Title: 3D Metal Printing: Is It Really Your Wallet’s Best Friend?

(is 3d metal printing cheaper)

1. What Exactly is 3D Metal Printing?

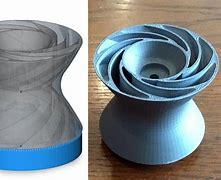

Forget plastic trinkets. 3D metal printing builds solid, usable metal parts directly from a digital file. Think of it like a super-precise robotic welder building things layer by tiny layer. Instead of cutting away metal from a big block (like traditional machining), it adds metal only where needed. This process goes by fancy names like Metal Additive Manufacturing (AM), Direct Metal Laser Sintering (DMLS), or Selective Laser Melting (SLM). Different machines use lasers or electron beams to fuse fine metal powder, melting it point-by-point following the computer’s exact blueprint. The result? Complex shapes, internal channels, and lightweight structures often impossible to make any other way. It’s manufacturing, but built digitally from the ground up.

2. Why the “Cheaper” Question is So Tricky for 3D Metal Printing

“Is 3D metal printing cheaper?” sounds simple. The answer is frustratingly complex. It depends heavily on what you’re making, how many, and why. Comparing it directly to traditional methods like CNC machining or casting is like comparing apples and moon rocks. Traditional methods often win hands-down on cost for simple, high-volume parts. The raw material for machining (a solid block) is usually cheaper per pound than the specialized powder for 3D metal printing. Setup for machining might be faster too. But 3D metal printing shines where complexity is free. Imagine a part with intricate cooling channels inside it. Machining that would take hours of skilled labor, special tools, and create tons of waste metal. 3D metal printing just builds it, hollow channels and all, in one go, with minimal waste. So, “cheaper” isn’t a flat yes or no. It’s about the specific part, quantity, and the hidden costs of complexity, waste, and assembly in traditional methods.

3. How Costs Break Down in 3D Metal Printing

Understanding the cost drivers helps see where savings might happen. First, the 3D metal printing machine itself is a major investment. Industrial machines cost hundreds of thousands, sometimes millions, of dollars. This cost gets spread over the parts it makes. Then comes the material. Metal powders (like titanium, stainless steel, aluminum alloys) are specially made for this process. They cost significantly more per kilogram than bulk metal stock. The printing process takes time, often hours or even days for a single part, consuming electricity and machine time. After printing, the part isn’t ready. It needs careful removal from the build plate, and crucially, extensive post-processing. This includes removing support structures (extra printed material holding the part during printing), stress-relieving heat treatment, and often precision machining or surface finishing to meet final tolerances. Post-processing can sometimes cost as much as the printing itself! So, the “print cost” is only part of the story.

4. Applications Where 3D Metal Printing Saves Real Money

So when does 3D metal printing become the cost-effective choice? It excels in specific niches. Aerospace loves it. Making a single, ultra-lightweight, complex titanium bracket for a jet engine using 3D metal printing can replace multiple heavier parts. The weight savings over the plane’s lifetime in fuel costs far outweigh the higher part cost. Same for rocket engines with intricate cooling channels. Medical implants are another winner. Creating a custom, porous titanium hip implant perfectly matching a patient’s bone structure is feasible only with 3D metal printing. The value of a perfect fit and faster healing justifies the cost. Tooling is a smart application. Printing a complex conformal-cooled mold insert for plastic injection molding might cost more upfront. But the drastically improved cooling slashes cycle times, boosting production speed and saving massive money over thousands of parts. Low-volume, high-value parts, complex prototypes, and consolidated assemblies (turning 10 parts into 1) are where 3D metal printing often finds its economic sweet spot.

5. 3D Metal Printing Cost FAQs

Let’s tackle those burning cost questions head-on:

Is the powder the main cost? Not usually. While expensive, machine time and especially post-processing often dominate the total cost per part. Powder cost is significant but rarely the biggest slice.

Will printer prices drop soon? Prices are gradually decreasing, especially for smaller or less capable machines. But top-tier industrial systems for critical parts remain high. Expect steady improvement, not a sudden crash.

Is it cheaper for prototypes? Absolutely, often yes. For complex metal prototypes, 3D metal printing can be much faster and cheaper than machining a one-off. You avoid expensive tooling setup and get the part in days, not weeks.

Does part size affect cost a lot? Yes, significantly. Larger parts take more machine time, use more powder, and require larger, more expensive machines and post-processing equipment. Cost scales up quickly with size.

(is 3d metal printing cheaper)

When is it clearly NOT cheaper? For simple shapes, especially in high volumes (hundreds or thousands). Traditional casting or machining will almost always be cheaper per part. Also, if your part only needs basic materials and simple geometry, stick with conventional methods. 3D metal printing isn’t a magic bullet for every metal part.