Discover a professional 3D printing powder supplier

Title: Metal Magic: Is 3D Printing the Real Deal?

(is 3d metal printing practical)

So you’ve heard about 3D printing. Maybe you saw a cool plastic toy made on one. But what about metal? Can we really print strong, usable metal parts? Is 3D metal printing just a fancy lab trick, or is it actually practical for real work? Let’s dive in and find out.

1. What is 3D Metal Printing?

Think of a regular inkjet printer. Instead of ink, imagine it spraying tiny layers of metal powder. Then, a powerful laser or electron beam zaps that powder. It melts the metal exactly where the computer tells it to. The printer lays down one super-thin layer of powder. Then it melts the pattern for that layer. It repeats this over and over. Slowly, a solid metal object builds up from nothing. It’s like magic, but it’s science. This process has fancy names like Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). But the basic idea is the same. It builds complex metal shapes layer by layer.

2. Why Consider 3D Metal Printing?

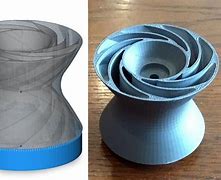

Why would anyone choose this over traditional metalworking? It offers some big advantages. First, it can make shapes that are impossible to cast or machine. Think of parts with crazy twists, internal channels, or super-fine lattices inside. This freedom opens doors for lighter, stronger designs. Second, it’s great for making one-off parts or small batches. Making a metal mold for casting is expensive and slow. 3D printing skips that step. You just send the digital file to the printer. This is perfect for prototypes, custom medical implants, or specialized tools. Third, it can combine parts. Instead of welding or bolting pieces together, you can print them as one single piece. This often means fewer weak spots and better performance.

3. How Does 3D Metal Printing Work?

Let’s get a bit more specific about the process. It starts with a 3D computer model. Software slices this model into hundreds or thousands of super-thin layers. The printer has a build chamber. Inside this chamber is a platform that can move down. A thin layer of fine metal powder is spread across the platform. A high-power laser beam or electron beam then moves across the powder. It melts the powder particles following the pattern for that first slice. The platform lowers slightly. Another layer of powder is spread on top. The laser melts the new layer, fusing it to the layer below. This repeats until the entire part is built. After printing, the part is still surrounded by loose powder. This powder supports the part during printing. The part is removed from the powder bed. It often needs extra finishing. This might involve cutting it off the build plate, sandblasting, heat treatment, or even machining to get a perfect surface. The unused powder is usually collected and reused.

4. Where is 3D Metal Printing Used?

This technology is finding its place in many industries. Aerospace companies love it. They use it to make lighter, stronger parts for jets and rockets. Think fuel nozzles, turbine blades, and complex brackets. Weight savings here mean huge fuel savings. The medical field benefits hugely. Surgeons get custom implants perfectly shaped to a patient’s bone. Dental labs create crowns and bridges faster. Even complex surgical tools are printed. The automotive industry uses it for high-performance parts. Think custom engine components, lightweight brackets, and even parts for racing cars. It’s also big in tooling. Companies print specialized jigs and fixtures for their assembly lines. These tools hold parts in place during manufacturing. Making these tools traditionally takes weeks. Printing can take days. Even the energy sector uses it. They print parts for turbines and drilling equipment. Sometimes it’s for prototypes. Other times, it’s for end-use parts in hard-to-reach places.

5. 3D Metal Printing: Your Questions Answered

People have lots of questions about this technology. Let’s tackle some common ones.

Is it strong? Yes, absolutely. Printed metal parts can be just as strong as traditionally made parts. Sometimes even stronger. This is because the process allows for optimized internal structures. Proper heat treatment after printing also ensures strength.

How much does it cost? It’s not cheap. The printers themselves cost a lot. The metal powders are expensive too. Printing a part can be costly compared to mass production methods like casting. But it saves money for low volumes, complex parts, or urgent needs. You avoid tooling costs. As the technology improves, costs are slowly coming down.

How fast is it? It’s slower than stamping out parts. Printing a complex metal part can take many hours, sometimes even days. It’s not yet suitable for high-volume production lines. But it’s getting faster. And for prototypes or custom parts, the speed can be much better than traditional machining.

What metals can be printed? A growing list! Common ones include titanium alloys (great for aerospace and medical), stainless steels (versatile and strong), aluminum alloys (lightweight), nickel superalloys (heat resistant), and even cobalt-chrome. New materials are being developed all the time.

Are the parts smooth? Straight off the printer, the surface is usually rough. It looks a bit like fine sandpaper. This is because of the layered process. For many functional parts inside machines, this is fine. If you need a smooth surface, you need to machine or polish it afterwards. This adds cost and time.

(is 3d metal printing practical)

Can I print anything? Almost! The design freedom is incredible. But you still need to follow some design rules. Features can’t be too thin. Overhangs might need support structures during printing. Engineers are learning how to design specifically for this process to get the best results.