Discover a professional 3D printing powder supplier

German Titans vs American Mavericks: Who Rules the Metal 3D Printing Roost?

(is german 3d printing better than desktop metal)

Metal 3D printing heats up. Two giants dominate the babble: the precision-focused German giants and the disruptive force known as Desktop Metal Yet which one absolutely forms the future? We dive deep into the triggers flying in between German design quality and American innovation.

Main Item Keywords: German 3D Printing, Desktop Metal.

1. What Makes German 3D Printing Tick? Accuracy, Power, and Process. .

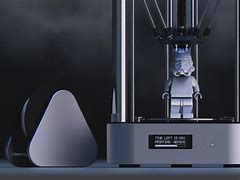

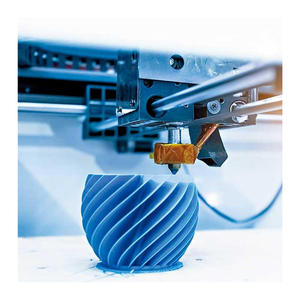

German 3D printing implies significant commercial machinery. Think big names like EOS, SLM Solutions, Trumpf. These aren’t enthusiast printers. They are factory-floor monsters developed for requiring tasks. Their core modern technology is frequently Laser Powder Bed Fusion (LPBF). A high-powered laser diligently thaws fine steel powder, layer by layer, inside a sealed chamber full of inert gas. This procedure supplies incredible information and strength. The parts come out thick, near net-shape, and prepared for tough jobs. German devices do not murmur. They purr with the noise of heavy-duty design. Anticipate robust construction, advanced procedure monitoring, and deep integration with automation. They target aerospace, medical implants, high-end automobile– sectors requiring absolute integrity and top-tier material properties. The German approach worths shown technology, extensive standards, and building makers implied to run for years under heavy lots.

2. Why Desktop Metal Trembled the Sector: Speed, Simpleness, and Access. .

Desktop computer Steel ruptured onto the scene shouting concerning interruption. Their concept? Make steel 3D printing much faster and easier. They saw LPBF makers as also slow, as well complex, as well expensive for numerous producers. Their flagship remedy, the Manufacturing System, utilizes a various technique: Binder Jetting. Consider it like a commercial inkjet printer, yet splashing a liquid binder onto layers of metal powder. This binds the powder fragments with each other loosely. Then comes the clever component: the delicate “environment-friendly” parts enter into a furnace. An unique process called sintering changes the binder with solid steel, reducing the part to its last density. This method is possibly much faster than LPBF, especially for making several components simultaneously. Desktop Steel intended directly at the production flooring. They wished to replace traditional machining for sure parts. Their assurance: lower cost per part, simpler procedure, and systems made for volume manufacturing, not simply prototyping. They targeted markets such as automotive, consumer goods, and commercial equipment makers needing lots of metal parts promptly.

3. Exactly how Do They In fact Contrast? Head-to-Head on Secret Aspects. .

Putting German LPBF versus Desktop Metal’s Binder Jetting reveals clear compromises. Surface finish and detail? German LPBF typically wins. The laser melting creates smoother surfaces and finer functions. Product residential or commercial properties? LPBF parts commonly have higher thickness and much better mechanical stamina, vital for important elements. Material choice? LPBF currently supports a wider variety of high-performance alloys. Currently, speed and expense? Below, Desktop Metal’s Binder Jetting aims to control. Building an entire layer at once is quicker than mapping it with a laser. Binder Jetting can pack the develop volume densely with components, reducing the expense for each one. Complexity? Operating a German LPBF equipment requires considerable know-how. Managing the inert gas ambience, laser criteria, and support frameworks is complicated. Desktop Metal’s process is easier. Print the environment-friendly parts, then sinter them. Assistance structures are marginal or different. Volume manufacturing? Desktop Metal explicitly targets high-volume outcome. German LPBF is frequently utilized for lower volumes of high-value components. The selection depends: need the absolute ideal product performance? Lean German. Required great deals of parts fast and cost-effectively? Desktop Steel looks strong.

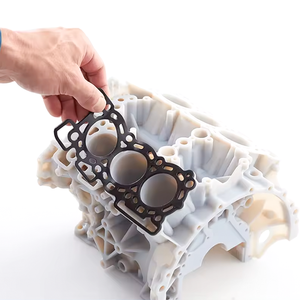

4. Applications: Where Each Modern Technology Beams Brightest. .

Various devices for various tasks. German LPBF excels where product stability is non-negotiable. Think jet engine generator blades, complex gas nozzles, spinal implants, or facility tooling inserts. These components deal with severe tension, heat, or require biocompatibility. The accuracy and strength of LPBF are essential. Its capability to create complex internal networks impossible to machine is a significant plus. Desktop computer Metal’s Binder Jetting finds its wonderful place in quantity. Required countless brackets, real estates, warmth sinks, or fluid system elements? Binder Jetting aims to make this affordable. It’s terrific for get rid of simpler geometries created wholesale. Automotive suppliers use it for lightweighting components. Durable goods firms discover it for complex styles formerly as well pricey. Commercial devices makers utilize it for sturdy jigs, components, and replacement components. It brings steel 3D printing closer to the economics of typical automation techniques for ideal components.

5. Frequently asked questions: Your Burning Questions Answered. .

Individuals ask these concerns frequently. Can Desktop computer Steel suit German LPBF top quality? Not rather yet for the most demanding applications. Binder Jetting components are getting better, however LPBF still holds the edge in best thickness and toughness. Which is cheaper? It depends. Desktop computer Metal usually wins on expense per component for high-volume manufacturing runs. German LPBF devices have a high preliminary expense, but also for low-volume, high-value components, they can be affordable. Is Desktop computer Metal easier to use? Generally, yes. The printing process itself is easier. The sintering action needs careful control yet is less complex than managing an LPBF construct. What concerning materials? LPBF offers much more unique alloys today. Desktop Metal sustains typical metals like stainless-steels, device steels, and is increasing. Is German technology outdated? Vice versa. They continually innovate, boosting rate, automation, and process control, focusing on their high-performance specific niche. Who wins? There’s no single winner. German LPBF regulations supreme for vital, high-performance parts. Desktop Steel leads the fee for high-volume production of less geometrically complex components. The best option depends completely on your details component needs and production goals.

(is german 3d printing better than desktop metal)

Both courses push limits. German engineers refine a tried and tested champion. Desktop computer Metal bets large on a quicker future. The competition just makes steel 3D printing stronger for everybody.